- Product Details

- {{item.text}}

Quick Details

-

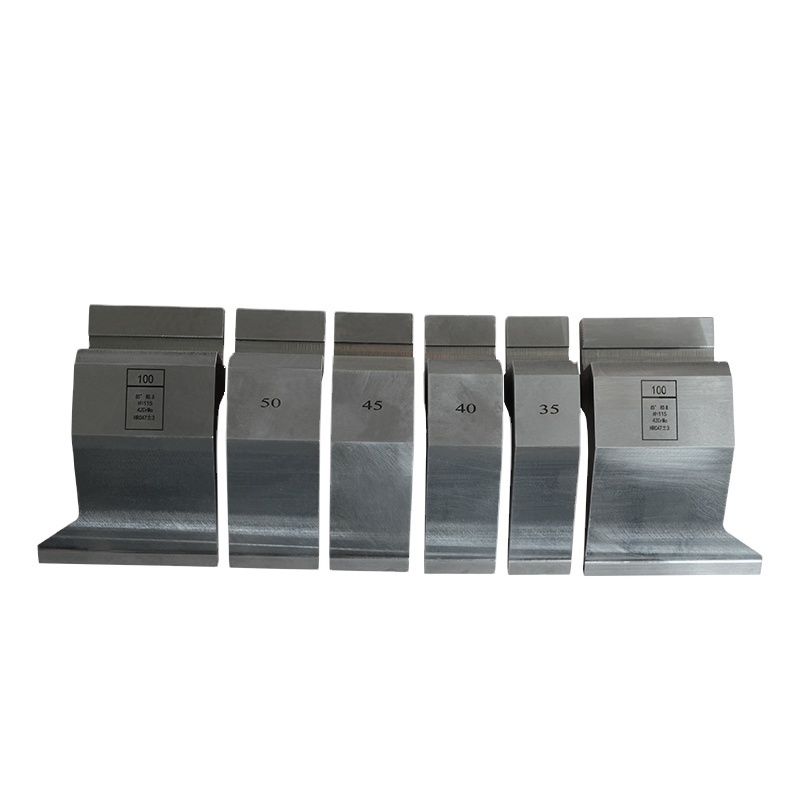

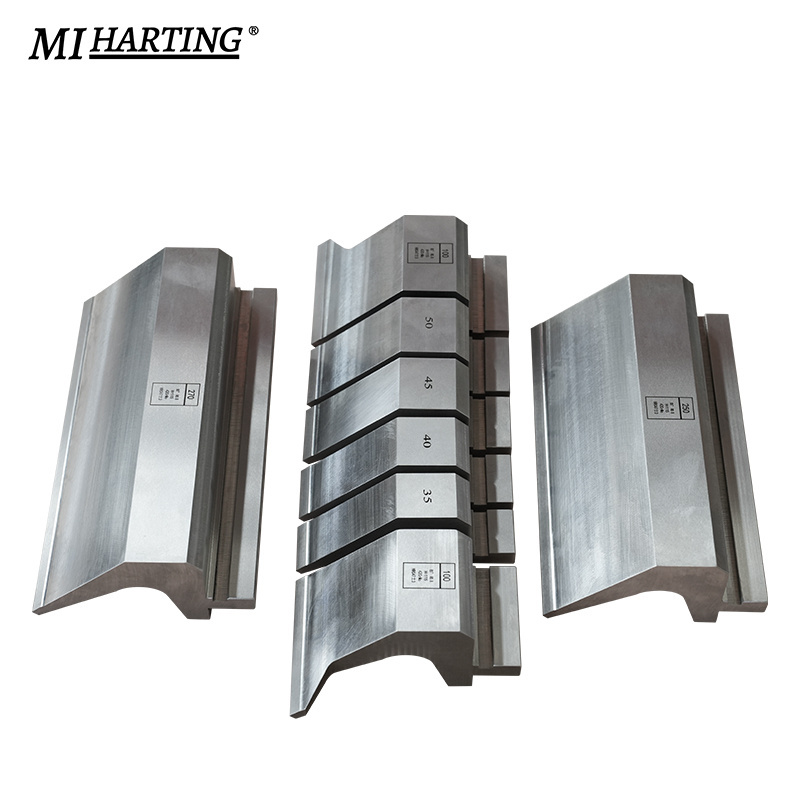

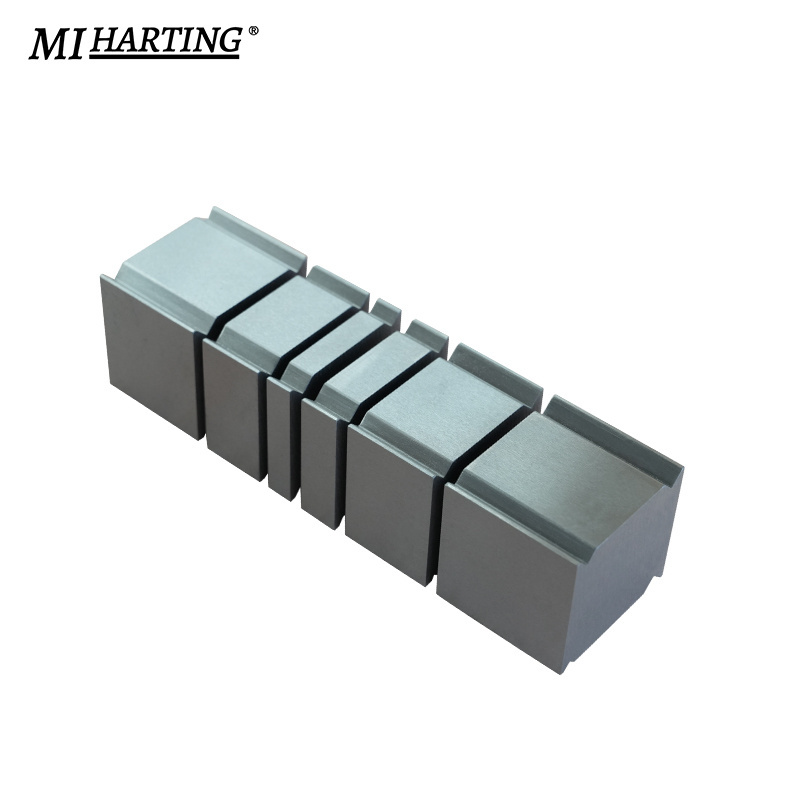

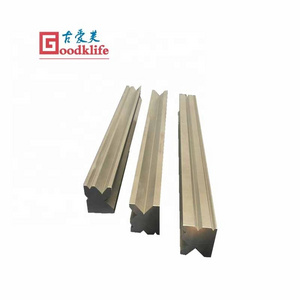

Product Name:

-

Press Brake Tooling

-

Material:

-

42CrMo

-

Surface treatment:

-

Heat Treatment

-

Application:

-

Industry

-

Drawing Format:

-

3D.STP. STEP

-

MOQ:

-

1 Pcs

-

Service:

-

OEM/ODM

-

Delivery Time:

-

25-30 Days

-

Package:

-

Wooden Box

-

Hardness:

-

HRC47+/-2

Quick Details

-

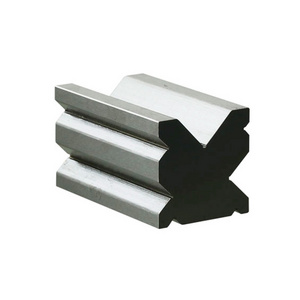

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Miharmle

-

Product Name:

-

Press Brake Tooling

-

Material:

-

42CrMo

-

Surface treatment:

-

Heat Treatment

-

Application:

-

Industry

-

Drawing Format:

-

3D.STP. STEP

-

MOQ:

-

1 Pcs

-

Service:

-

OEM/ODM

-

Delivery Time:

-

25-30 Days

-

Package:

-

Wooden Box

-

Hardness:

-

HRC47+/-2

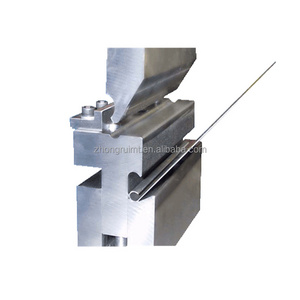

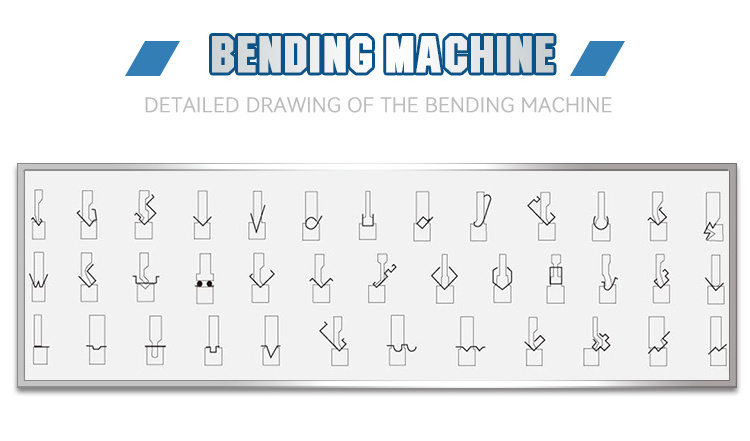

Product Description

Our Workshop

PRESS BRAKE TOOLING Q&A

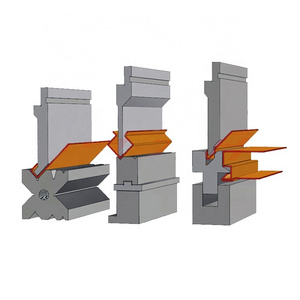

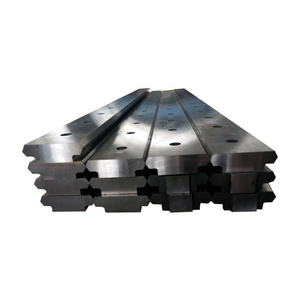

Q1.Do you know what the sheet metal material, thickness, workpiece length, machine model or clamping method determine?

A: different materials have different rebound coefficients. Especially for arc molds, the thicker the sheet, the smaller the

rebound coefficient. The thickness of the sheet determines the width of the bottom die notch.The work piece length determines the die length.And different model machine, different clamping method. This determines the shape of the upper die handle.

Our engineers will design the initial drawing of the tooling based on these data, generally we will check the drawings with the customer within 12 hours. Besides common toolings, we can also customize Amada and Trumpf toolings.

Q2.Do you know what are the advantages of the two materials 42CRMO and 55CRSI?

A: 42CRMO material has good toughness and wear resistance;

The quenching hardness of 55CRSI material is higher.

We will make according to the requirements of customers. If you don't know which material to use, our engineers will help you.

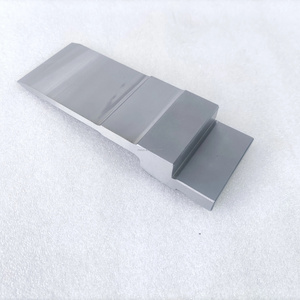

Q3. Do you know the step of raw material forging in the process? What are its benefits?

A: ①The impurities in the material are discharged, and the carbon structure is tighter.

②Forged to the required size for easy processing.

Q4. Do you know vacuum insulation?

A: After the heat treatment and rough grinding of the mold, we will have a step of vacuum insulation, the purpose is to protect the life of the mold, so that the mold is not easy to crack and more wear-resistant. Some factories do not have this step in the production process, which greatly reduces the life of the mold. So next time, when you purchase molds, be sure to ask the factory if they do this step!

Q5. Do you know why the acceptance process runs through the entire mold manufacturing process?

A: ①First inspection: to check before each process, check whether it meets the requirements and whether the previous step is completed

②Process inspection: check in each process

③Final inspection: We will check on the marble working platform, because the marble material is more stable, there will be no changes in thermal expansion and contraction, and the straightness is good.

Q1.Do you know what the sheet metal material, thickness, workpiece length, machine model or clamping method determine?

A: different materials have different rebound coefficients. Especially for arc molds, the thicker the sheet, the smaller the

rebound coefficient. The thickness of the sheet determines the width of the bottom die notch.The work piece length determines the die length.And different model machine, different clamping method. This determines the shape of the upper die handle.

Our engineers will design the initial drawing of the tooling based on these data, generally we will check the drawings with the customer within 12 hours. Besides common toolings, we can also customize Amada and Trumpf toolings.

Q2.Do you know what are the advantages of the two materials 42CRMO and 55CRSI?

A: 42CRMO material has good toughness and wear resistance;

The quenching hardness of 55CRSI material is higher.

We will make according to the requirements of customers. If you don't know which material to use, our engineers will help you.

Q3. Do you know the step of raw material forging in the process? What are its benefits?

A: ①The impurities in the material are discharged, and the carbon structure is tighter.

②Forged to the required size for easy processing.

Q4. Do you know vacuum insulation?

A: After the heat treatment and rough grinding of the mold, we will have a step of vacuum insulation, the purpose is to protect the life of the mold, so that the mold is not easy to crack and more wear-resistant. Some factories do not have this step in the production process, which greatly reduces the life of the mold. So next time, when you purchase molds, be sure to ask the factory if they do this step!

Q5. Do you know why the acceptance process runs through the entire mold manufacturing process?

A: ①First inspection: to check before each process, check whether it meets the requirements and whether the previous step is completed

②Process inspection: check in each process

③Final inspection: We will check on the marble working platform, because the marble material is more stable, there will be no changes in thermal expansion and contraction, and the straightness is good.

Hot Searches