- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

A-300, A-500,A-1000,A-2000

-

Power:

-

As Requirements

-

Material:

-

Standard Packaging

-

Marketing Type:

-

New Product 2024

-

Weight (KG):

-

5000 kg

-

Product name:

-

Waste Battery Recycling Machine

-

Feature:

-

Easy Operation;High Seperation Ratio

-

Voltage:

-

220V/380V/Customized

-

Application field:

-

All Kinds Of Lithium Batteries

-

Color:

-

Customer's Requirement

-

Application:

-

Lithium Battery Manufacturer

-

Raw material:

-

Used Lithium Ion Battery

-

Final product:

-

Lithium Cobalt Powder

Quick Details

-

Production Capacity:

-

500-2000KG

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Believe machinery, Believe

-

Model Number:

-

A-300, A-500,A-1000,A-2000

-

Power:

-

As Requirements

-

Material:

-

Standard Packaging

-

Marketing Type:

-

New Product 2024

-

Weight (KG):

-

5000 kg

-

Product name:

-

Waste Battery Recycling Machine

-

Feature:

-

Easy Operation;High Seperation Ratio

-

Voltage:

-

220V/380V/Customized

-

Application field:

-

All Kinds Of Lithium Batteries

-

Color:

-

Customer's Requirement

-

Application:

-

Lithium Battery Manufacturer

-

Raw material:

-

Used Lithium Ion Battery

-

Final product:

-

Lithium Cobalt Powder

Background

In recent years, with the rapid development of new energy vehicles, smart phones, portable electronic devices, etc., the demand for lithium-ion batteries is increasing day by day. However, the quality control during the manufacturing process as well as the treatment after use are facing great challenges. In this, the application of lithium battery sorting machine plays a vital role. Lithium battery sorting machine Important position in the field of circular economy and environmental protection.

Product Description

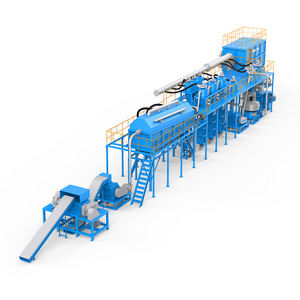

Lithium battery recycling machine

mainly comprises the following steps: after discharging the recovered waste batteries, crushing, magnetic separation, air separation, crushing, gravity separation, screening and other processes are carried out by mechanical equipment.

Raw materials & final products

The Electric Car Traction Battery Lithium Ion Battery Recycling Machine is used for dismantling and recycling the soft package battery, cellphone battery, shell battery, cylindrical battery etc. Different types of lithium batteries have different recycling procedures.

The final products of Battery Lithium Ion Battery Recycling Machine is graphite powder, cobalt acid lithium,aluminum and copper.

Work Process

Shredder -- Hammer Crusher -- Grinder -- Separation Machine -- Pulse Dust Collector -- Classifying Screen -- Magnetic Machine -- Gravity Separator -- High-pressure Blower

Packing & Delivery

We can produce different size according to your pharameter requirement. and we allow proper discount according to the quantity you order.

Customer Visit

Until now, we have customers more than 130 countries, Indonesia, India, Malaysia, Laos, Myanmar, Thailand, Vietnam,Philippines,Pakistan, Sri Lanka, Lebanon, Georgia, Turkey, Poland, Czech, Mongolia, South Korea, Romania, Egypt, Sudan, Tunis,Algeria, Ethiopia, Tanzania Equatorial Guinea, Zambia, Mexico, South Africa, etc.

You're welcome if you'd like to visit our factory! You can contact us now!

Specification

|

WORKING PERFORMANCE

|

|

|

|

Raw Material

|

Lithium Battery

|

|

|

Final Product

|

Mainly Copper, Aluminum, Lithium Cobalt Oxide, Graphite Powder

|

|

|

Technical Parameters

|

|

|

|

Mold

|

Capaticy

|

|

|

A-300

|

300 kg/h

|

|

|

A-500

|

500kg/h

|

|

|

A-1000

|

1000 kg/h

|

|

|

A-1500

|

1500 kg/h

|

|

|

Working voltage:380V

|

|

|

Working voltage:380±10V(415V ,440V also can be custom)

(If you want more detailed parameters and quotations, please contact us.)

About us

Our company has a plant of more than 10,000 square meters, is a focus on R & D, production, sales as one of the

machinery and equipment manufacturers

. So far, the company's products have passed

more than 20 national patents

, but also

through the ISO, TUV, CE and other quality system certification.

Adhering to the business philosophy of

quality and service

, the company is dedicated to providing

quality product services

for new and old customers to meet customer needs to the maximum extent.

Hot Searches