- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

33.5-116 KW

-

Dimension(L*W*H):

-

10*6*4.5m

-

Weight:

-

8000 kg

-

Brand name:

-

Hengyuan

-

Name:

-

Pulp molding egg tray machine

-

Factory visit:

-

Welcome

-

Color:

-

Customized

-

Capacity:

-

500-5000 pcs/hour

-

Raw material:

-

Paper waste, pulp, pulp waste

-

Final product:

-

Egg tray, fruit tray

-

Layout:

-

Reasonable structure

-

Process type:

-

Pulp molding machine

-

Drying system:

-

Metal drying, earth kiln drying

Quick Details

-

Production Capacity:

-

500-5000PCS/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hengyuan

-

Voltage:

-

220V/380V

-

Power:

-

33.5-116 KW

-

Dimension(L*W*H):

-

10*6*4.5m

-

Weight:

-

8000 kg

-

Brand name:

-

Hengyuan

-

Name:

-

Pulp molding egg tray machine

-

Factory visit:

-

Welcome

-

Color:

-

Customized

-

Capacity:

-

500-5000 pcs/hour

-

Raw material:

-

Paper waste, pulp, pulp waste

-

Final product:

-

Egg tray, fruit tray

-

Layout:

-

Reasonable structure

-

Process type:

-

Pulp molding machine

-

Drying system:

-

Metal drying, earth kiln drying

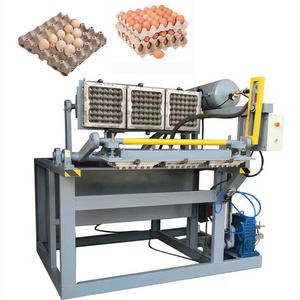

High Performance Pulp Molding Egg Tray Machine

Brief instruction of pulp molding egg tray machine

Pulp molding egg tray machine is making pulp egg tray machine suitable for egg long-distance transportation. Mainly by the molding machine, hydraulic pulper, vacuum dryer, air

compressor and drying box and other machinery this mahcine with the advantages of no pollution, lower cost and high performance, is easy to operated.

Technical parameter for pulp molding egg tray machine

Pulp molding egg tray machine have different capacity, it mainly according mahcine's forming mold and transferring mold, you could choose the mahcine according the machine's capacity and your budget.

|

Type |

Capacity(pes/h) |

Mold |

Main power |

Drying consumption |

|

HY-2 |

100-500 |

1 side 2 forming mold 2 transferring mold |

28KW |

Drying by sun |

|

HY-4 |

800-1000 |

1 side 4 forming mold 4 transferring mold |

33.5KW |

2ton/24 hours coal |

|

HY-16 |

2000-2500 |

4 side 16 forming mold 4 transferring mold |

60KW |

2.2ton/24 hours coal |

|

HY-32 |

3500-5500 |

8 side 32 molding mold 4 transferring mold |

116KW |

2.5ton/24 hours coal |

Main advantages of pulp molding egg tray machine

1. Pulp molding egg tray machine could produce such as egg tray, egg box, fruit tray, coffee

tray.

2.Material for the molded pulp products is waste paper, corrugated paper, waste newspaper, magazine.

3.Semi-automatic control, PLC+Touch screen controller.

4.Stainless steel pulp tank, the surface of platens covered with stainless steel.

5.Transferred to a flat-bed automatically.

Working process for pulp molding egg tray machine

Pulping system

Pulp system is the first step of pulp molding egg tray machine , the system main equipment is hydraulic pulper, grinding mahcine, and pulp pump, ans ect, it's for process raw material and paper pulp.

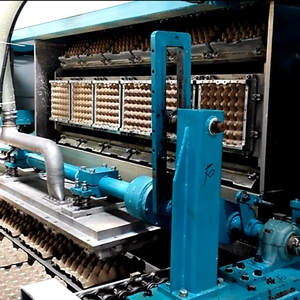

Molding system

Molding system is the main system for pulp molding egg tray machine , it mainly include automatic egg tray molding machine, egg tray forming mold, vacuum pump, it's for forming and mold egg tray.

Drying system

Drying sysetm is the laste system for pulp molding egg tray machine , it's for drying the egg tray, we have serval type drying system, for the small cpapcity, we suggest dry by sunshine, if the machine have a bigger cpapcity, we have two type's drying system, earth kiln drying and metal drying.

Final product of pulp molding egg tray machine

We could design the egg tray size according your request and your egg tray sample.

Clients visited our factory for pulp molding egg tray machine

Shipment pictures for pulp molding egg tray machine

If you have requirements for pulp molding egg tray machine, please don't hesitate to contact with me as the followings: