- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JXSC

-

Dimension(L*W*H):

-

depending on model

-

Weight:

-

KG

-

Product name:

-

50 Tph Jaw Tyre Wheel Mobile Cone Crusher Mobile Crushing Plant

-

The Machines classification:

-

Crushing Line

-

Max feeding size:

-

300-700mm

-

Output size:

-

small size and cubic shape

-

Spare parts supply:

-

Anytime

-

Test&Installation:

-

Engineer Guide

-

Price:

-

Competetive (can Discuss

-

Processed Materials:

-

200 Kinds Materials(<300 Mpa)

-

Function:

-

Crushing Material

-

After sale Service:

-

Life Long Operation Time

Quick Details

-

Application:

-

mining, metallurgy, building, highway, railway

-

Capacity(t/h):

-

30-500t/h

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXSC

-

Dimension(L*W*H):

-

depending on model

-

Weight:

-

KG

-

Product name:

-

50 Tph Jaw Tyre Wheel Mobile Cone Crusher Mobile Crushing Plant

-

The Machines classification:

-

Crushing Line

-

Max feeding size:

-

300-700mm

-

Output size:

-

small size and cubic shape

-

Spare parts supply:

-

Anytime

-

Test&Installation:

-

Engineer Guide

-

Price:

-

Competetive (can Discuss

-

Processed Materials:

-

200 Kinds Materials(<300 Mpa)

-

Function:

-

Crushing Material

-

After sale Service:

-

Life Long Operation Time

Product Description

Instruction

WALKER 30TPH Mobile Basalt & River Stone Crushing Station, consisting of Vibrating Feeder, Fine Jaw Crusher, Vibrating Screen and Belt Conveyors, all equipment installed in a heavy-duty trailer with Two-axis, with rubber tires & wheel hub, we also supply electric cabinet for controlling, include the electric wires & cables.

It is a movable crushing plant, easy to adjust, convenient to operate, has low maintenance cost, and has very high crushing & screening productivity.

The station is widely used in mining, coal mining, and construction waste recycling mobile crushing, earthwork engineering, city infrastructure, road or construction sites and site operation. Using integrated design idea, reducing the installation of customer in the field of basic equipment and auxiliary equipment, and reduce the installation time. Unit compact and reasonable design, reduces the traditional stone line field area. It is Convenient to site change, and reduce customers second basic input.

Application Field

Quarry, mining, coal mining, dry powder mortar, concrete mixing station, power plant desulfurization, quartz sand, etc.

Vibrating Feeder.

1.WALKER DN series Vibrating Feeder is a heavy duty feeding machine, use vibration to feed material evenly and automatically to the next crushing machine.

2. It has grizzly bar to block bigger size stones/rocks, an easy-to-use and high performing feeding machines, better rates of efficiency and less dependency on man power.

3. Hot selling vibratory feeder models are DN380*96, DN490*110, DN590*110

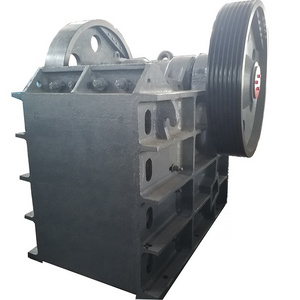

Fine / Secondary Jaw Crusher.

1. Suitable for crushing all kinds of stones and ores to medium fine size, like Granite / Basalt / Limestone / River stone / Marble / Quartz / Pebble Mountain Stone / Gold ore / Iron ore / Copper ore....

2. WALKER Jaw Crusher enjoys very high crushing ratio & customized crushing capacity.

3. our hot selling models are PE150*250, PE250*400, PE400*600, PE500*750, PE600*900, PE750*1060, PEX150*750, PEX250*1200, PEX300*1300...

Vibrating Screen.

1. WALKER Vibration Screen has our own advantages: Steel plate bending, No welding parts, very wear resistance manganese steel wire woven screen.

2. It can be featured with 2 layers, 3 layers, 4 layers, used to sort and classify the materials according to the particle size by its circular vibration.

3. Our hot selling models are 2YD1225, 2YD1230, 3YD1530, 3YD1548, 4YD1860

Suitable Material

Pebble, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold, copper, etc.

Performance characteristics of our products

● The chassis design of steel track, high strength, good passing ability, wide adaptation range, mountain, wetlands can be used.

● The diesel engine, reliable performance and low fuel consumption, low noise, high economy.

● High integration degree of equipment, can realize step-less self-running, simple operation, accurate control.

● According to customer requirements, the configuration of different crushing equipment and screening feeding equipment.

● Compact structure, stable performance. Strong control, reduce the transportation cost and work load.

Complete varieties

Complete varieties of mobile crushing station, specifications series, give you more choice. According to the different needs of customers, provide a diverse portfolio of mobile crushing equipment, to meet the customers production needs.

Based on single machine, combination can be divided into: Cone crusher screening combined mobile station, impact crusher screening combined mobile station, etc. Other mobile devices can be multistage crush combination in various forms according to the specific requirements.

Technical parameters

As an OEM & ODM in gold recovery equipment with rich experience and many Independent Intellectual Property Rights, JXSC Mine Machinery provide different models of mobile crushing station with different dimension sizes and capacity.

Here is a list of our most hottest models, if you want more specific parameters, you can directly contact us.

|

Mobile Jaw Crusher Station

|

Rotor Spec (mm)

|

Feed opening size (mm)

|

Max Feed edge(mm)

|

Capacity (t/h)

|

Motor Power(kw)

|

Weight(t)

|

||||||

|

Model

|

Vibrating grizzly feeder

|

Jaw Crusher

|

Belt machine Specification

|

Capacity

(t/h)

|

Power

(kw)

|

Max size

(L * W * H)(mm)

|

||||||

|

DN938P69

|

DN380×95

|

PE600×900

|

B800×8M

|

70-150

|

91.5

|

13200×2900×4700

|

||||||

|

DN1142P710

|

DN420×110

|

PE750×1060

|

B1000×11M

|

90-200

|

134

|

15000×3100×5100

|

||||||

|

DN1349P129

|

DN490×130

|

PE900×1200

|

B1200×13M

|

150-300

|

146

|

17000×3300×5600

|

||||||

|

Mobile Impact Crusher Station

|

|

|

|

|

|

|

||||||

|

Model

|

Circle Vibrating screen

|

Impact Crusher

|

Belt machine Specification

|

Capacity

(t/h)

|

Power

(kw)

|

Max size

(L * W * H)(mm)

|

||||||

|

3YD1848F1210

|

3YD1848

|

PF-1210

|

B650×7M

|

70-300

|

128.5-150.5

|

12500×3000×6500

|

||||||

|

3YD1860F1214

|

3YD1860

|

PF-1214

|

B650×8M

|

90-400

|

154-190

|

13500×3000×6500

|

||||||

|

3YD2160F1315

|

3YD2160

|

PF-1315

|

B800×8M

|

120-450

|

210-297

|

14000×3200×6800

|

||||||

|

Mobile Cone Crusher Station

|

1250*1050

|

400*1080

|

350

|

70-120

|

110-132

|

14.9

|

||||||

|

Model

|

Circle Vibrating screen

|

Cone crusher model

|

Belt machine Specification

|

Capacity

(t/h)

|

Power

(kw)

|

Max size

(L * W * H)(mm)

|

||||||

|

3YD1848DN10SX

|

3YD1848

|

DN1000S-X

|

B650×7M

|

70-300

|

99-134

|

13000×3000×6700

|

||||||

|

3YD1860DN12SX

|

3YD1860

|

DN1200S-X

|

B650×8M

|

120-400

|

212.5-220.5

|

14000×3000×6700

|

||||||

|

3YD2160HP200

|

3YD2160

|

HP200

|

B800×8M

|

140-450

|

257.5-264.5

|

14000×3200×6700

|

||||||

Packing & Delivery

◆ Ways of packing

1.Small parts packed in the wooden cases

2.Big parts packed by plastic membrane

3.The whole big machine is loaded in the container

3.The whole big machine is loaded in the container

◆ Shiping by sea/air freight

1. Usually our mining machines are shipped in 40'HQ or Flat Containers by sea.

2. Our mining equipments can be also shipped by air if customers request.

2. Our mining equipments can be also shipped by air if customers request.

Company Introduction

◆ Jiangxi walker Machinery Co.,Ltd

Jiangxi walker Machinery Co.,Ltd, are a professional manufacturer of complete set mining equipments, a sub-company of JXSC mine machinery factory in Jiangxi province.professional at providing complete set processing equipments for Gold ore /Tin ore /Tungsten ore /Iron ore / Diamond/ Coltan ore / Silica sand / Zircon sand/ Black sand/Chrome ore, ect. As well as complete set small lab mining machines.

1.Inquiry and consulting support.

2.Ore sample testing support.

3.View our Factory.

4.Design Flowchart.

2.Ore sample testing support.

3.View our Factory.

4.Design Flowchart.

1.Training how to instal the machine, training how to use the machine.

2. 1 year warranty .

3.Engineers available to service machinery overseas.

2. 1 year warranty .

3.Engineers available to service machinery overseas.

FAQ

1.How is the quality of your products?(mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will do a test on every machine before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description or promise we made before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before factory delivery, which is international trade practice; Finished product pictures will be provided to customers before delivery.

If you are interested in our products, please don't hesitate to contact us. Could you tell me the following questions, so that I can give you a complete solution, including best Exw-works Price Quotation!

1. Which machine do you need? like gold washing machine, spiral chute, vibrating screen, Jig separator, Shaking table, etc.

2. What is your raw ore that you plan to process? like gold ore, diamond ore, tantalite or silica sand, etc.

3. What is the capacity you need? Like 10 tones per hour.

4. What is the feeding size to the machine? and what is the discharging-material size that you require?

Sincerely welcome to send your inquiry,you can get best quotation and professional service.

Answer: Our products are manufactured strictly according to national and international standard, and we will do a test on every machine before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description or promise we made before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before factory delivery, which is international trade practice; Finished product pictures will be provided to customers before delivery.

If you are interested in our products, please don't hesitate to contact us. Could you tell me the following questions, so that I can give you a complete solution, including best Exw-works Price Quotation!

1. Which machine do you need? like gold washing machine, spiral chute, vibrating screen, Jig separator, Shaking table, etc.

2. What is your raw ore that you plan to process? like gold ore, diamond ore, tantalite or silica sand, etc.

3. What is the capacity you need? Like 10 tones per hour.

4. What is the feeding size to the machine? and what is the discharging-material size that you require?

Sincerely welcome to send your inquiry,you can get best quotation and professional service.

Hot Searches