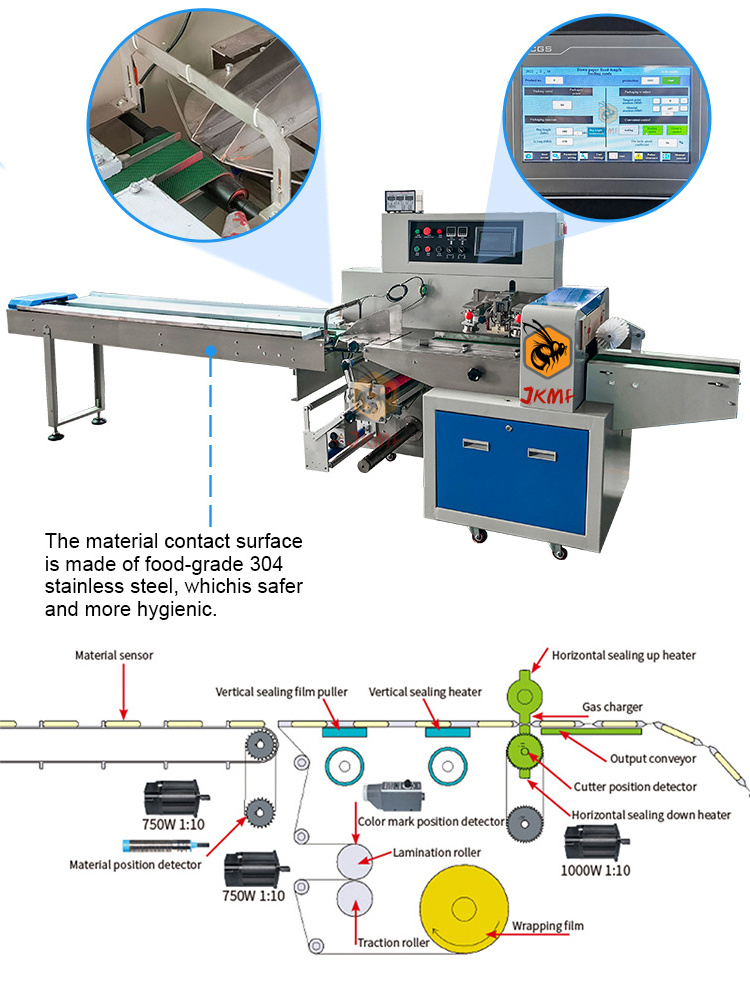

A pulse is generated for machine movement, and this is transferred to the PLC (programmable logic controller).

Including packaging size, packaging speed, etc.

|

Model

|

JK-250X

|

JK-350X

|

JK-450X

|

JK-600X

|

|||

|

Film Width

|

Max.250 mm

|

Max.350 mm

|

Max.450 mm

|

Max.600 mm

|

|||

|

Bag Length

|

45~190 mm

|

65~280 mm

|

120~450 mm

|

130~450 mm

|

|||

|

Bag Width

|

30~110 mm

|

50~160 mm

|

60~210 mm

|

60~280 mm

|

|||

|

Product Height

|

Max. 40 mm

|

Max. 45 mm

|

Max. 110 mm

|

Max. 110 mm

|

|||

|

Packing Speed

|

40~230 bags/min

|

40~230 bags/min

|

30~150 bags/min

|

30~150 bags/min

|

|||

|

Machine Size(mm)

|

3920*670*1320

|

4020*720*1450

|

3990*900*1468

|

3990*1000*1468

|

|||

|

Machine Weight

|

450KG

|

500KG

|

600KG

|

700KG

|

|||

|

Machine Voltage

|

220V, 50/60 Hz

|

|

|

|

|||

|

Machine Power

|

2.4KW

|

2.8KW

|

3.2KW

|

4KW

|

|||