- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

START, START

-

Voltage:

-

220v/380v

-

Power:

-

5.5

-

Dimension(L*W*H):

-

customized

-

Weight:

-

2000 kg

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Name:

-

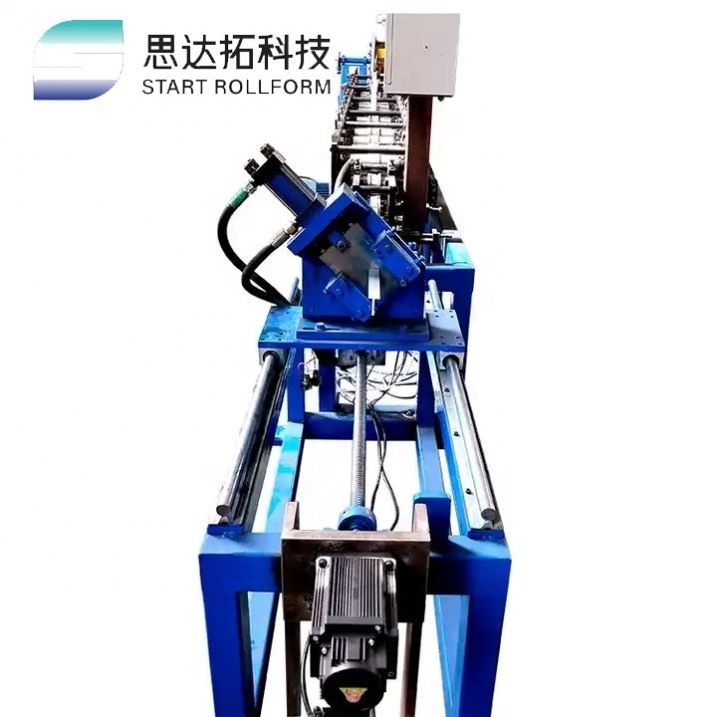

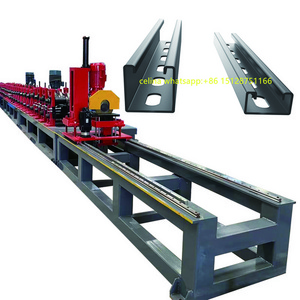

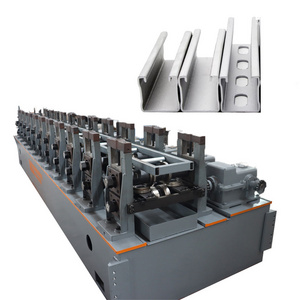

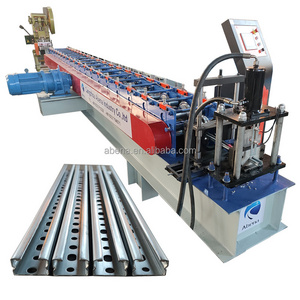

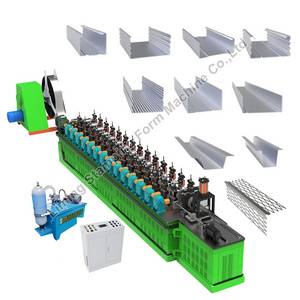

Strut Channel Cold Roll Forming Production Machine

-

Usage:

-

Construction Building Material

-

Keywords:

-

Telescopic channel cold forming production

-

Shaft material:

-

45# High Grade Steel

-

Roller material:

-

Cr12

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Production Capacity:

-

10-20 m/min

-

Place of Origin:

-

Jiangsu, China, China

-

Brand Name:

-

START, START

-

Voltage:

-

220v/380v

-

Power:

-

5.5

-

Dimension(L*W*H):

-

customized

-

Weight:

-

2000 kg

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Name:

-

Strut Channel Cold Roll Forming Production Machine

-

Usage:

-

Construction Building Material

-

Keywords:

-

Telescopic channel cold forming production

-

Shaft material:

-

45# High Grade Steel

-

Roller material:

-

Cr12

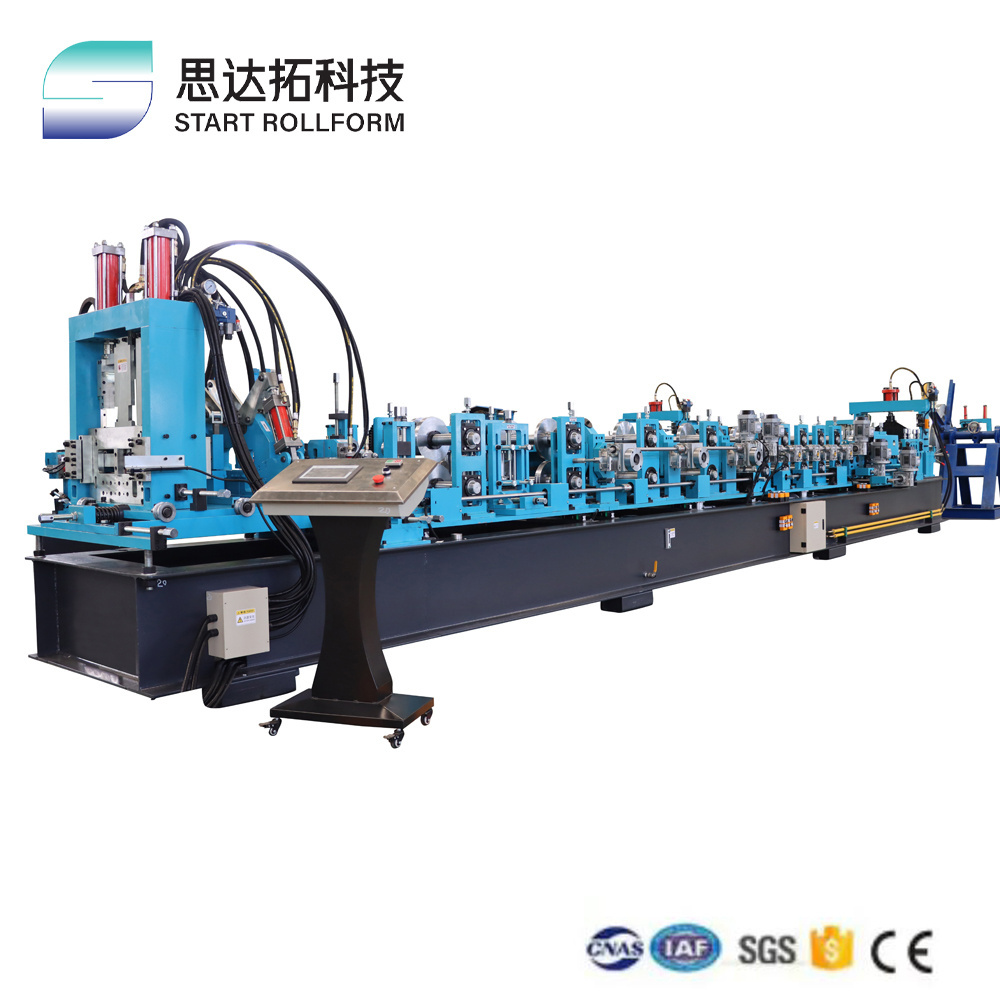

Suzhou Start Technology Co., Ltd. specializes in the production of metal roofing panel roll forming machines, metal wall panel roll forming machines, glazed tile roll forming equipment, arching roll forming machines, floor decking roll forming machines, CZ purlines roll forming machines, metal door frame roll forming machines, metal door panel equipment, rolling shutter door machines, rolling shutter door, U guide rail machines, light steel keel roll forming machines, high-speed guardrails road barrier roll forming machine, shelf racks roll forming machine, shelf panel equipment, metal silo equipment, photovoltaic support U stud equipment, seismic support equipment, metal embossing machine, shearing machine, slitting machine, rolling rotary punching equipment, hydraulic pressure of various tonnages Uncoilers, automatic stackers, and forming machines for some special-shaped profiles metal products, such as steel hoop forming punching and shearing machines, grape trellis bracket forming machines, etc.

Our Factory was one of the first manufacturers to produce roll forming machines, after years of development, our factory has grown and enjoyed a high reputation in the roll forming line industry. We develop and supply metal profile roll forming machines, turnkey lines and solutions for specific applications in the high-tech sector and customers with high technical requirements.

|

No.

|

Items

|

Unit

|

Main Specification

|

|

1

|

Material thickness

|

mm

|

0.3-1

|

|

2

|

Forming speed

|

m/min

|

10-20

|

|

3

|

Roll station

|

/

|

14 stations(depend on the profile)

|

|

4

|

Main power

|

kw

|

5.5

|

|

5

|

Hydraulic power

|

kw

|

3

|

|

6

|

Control system

|

/

|

PLC panasonic

|

|

7

|

Drive

|

/

|

by chain or gear turning

|

|

8

|

Shear material

|

/

|

cr12

|

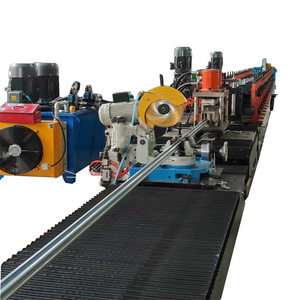

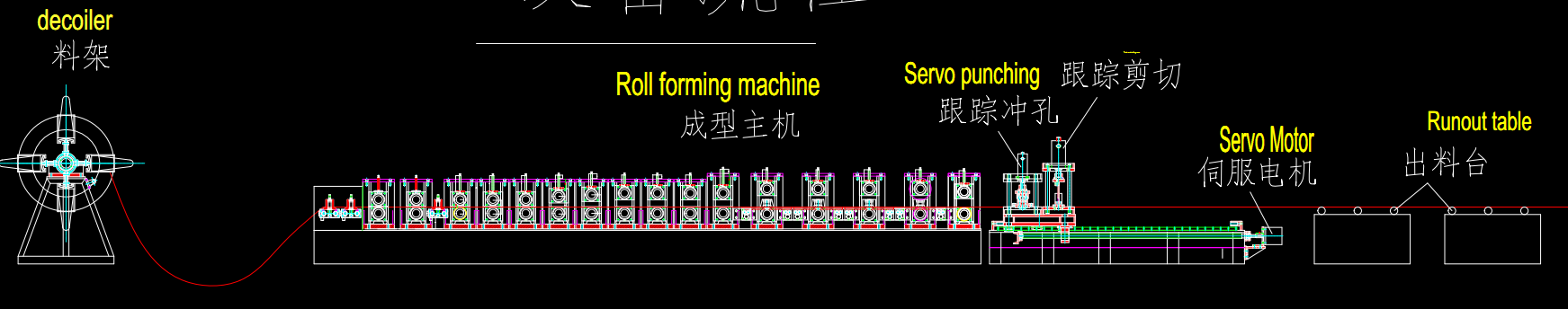

One complete Roll former is including below parts: de-coiler, leveling system, roll forming machine main body, hydraulic cutting system, hydraulic station and controlling table. Besides these, if there are hole on the profiles, also it needs the punching system, for big thickness material profile, need the press punching system. If customer want to save human labor, the automatic stacker can be designed and added to the roll forming line. Punching machines in the roll forming lines are High efficiency coil-fed punching machines and perforation lines.

In order to speed up the roll forming, high technology is updated, the tracking punching, tracking cutting, heavy duty gear box transmission, double layer designing for sheet panel, double production line for steel framing profiles, Automatic linear adjusting rollformers which can produce a range of sizes of profiles. Also for customers who want to save cost, we design the economical machine for adjusting size by changing certain small parts on the rollers and shafts.

Reliable manufacturing technology can meet the needs of customers' customized products. Diversified and flexible processing equipment, the ultimate goal is to guarantee efficient and flexible production in a short time. According to the profile or sheet that the customer needs to produce, we will evaluate which structure of the machine is more suitable, for example, is the front punching more suitable, or the post punching more suitable, the front cutting is more suitable, or the post cutting is more suitable? According to the thickness of the coil, the evaluation is which capacity decoiler is suitable, whether to use manual decoiler or hydraulica decoiler? According to the customer's requirements for speed, decide whether the transmission mode of the machine is chain drive, gear drive, or gear box drive? According to the arrangement and size of the hole pattern of metal products, it is judged whether the punching is online hydraulic punching, or punching first and then forming, etc. We will flexibly configure the parameters of the equipment according to the special products and the customer's positioning needs of the equipment.

Start has a professional team and manufactures 100% in-house to ensure that the highest quality standards are met consistently. Each of the parts on the roll forming machine we carefully tested well. We has proudly provided the industry’s best roll forming equipment to decades of countries hundreds of rollformers for over 15 years.

When we receive the customer's metal product drawings, or metal samples, or the customer's idea, we will combine the market classification, application and conventional size models of such metal profile products to give customers a basic positioning or some sample projects For reference, we will design the finished product based on the customer's ideas, such as where to add the safety edge of the product, where to add the logo, what is the appropriate waist height, how much the bottom edge, how much feeding thickness, how much space between the upper and lower rollers And so on, we will perfectly shape and design the product according to the customer's idea.We use reliable arc welding technology, which has a wide range of applications and is commonly used in all metal structures such as automobiles, railway vehicles, ships, aircraft, buildings and construction machinery. The base material is usually steel, but other metals such as aluminium and titanium are also used, and this arc welding guarantees a strong and durable machine weld!

Each department of the factory strictly controls the process of each production according to the ISO9001 quality system. We have advanced drawing software and high-performance machining equipments. We have rich experience in roll forming machine design and control system application will provide you with the best production solution.

For the inspection of the machining accuracy of the parts, we carry out strict inspections from different aspects, mainly from the following aspects: the inspection of the geometric accuracy of the parts, the inspection of the surface quality, the

inspection of the mechanical properties and the inspection of hidden defects.

We establish a comprehensive and strict quality management system, implement the 6 SIGMA quality plan, support customer service, design, quality, cost control and full on-time delivery, and continuously improve all business processes to lay the foundation for high-quality products.

We will strictly and carefully check the drawings of the metal profiles products with the customer and after the confirmation of the customer, we will carry out the production in an orderly manner. First, we will design the overall drawings of the machine, the drawings of each forming roller, and the machine. The design of each component roller, etc., and then put into production, followed by assembly, test operation, etc., this series of production processes will be arranged in an orderly manner, with the fastest time, about 30-45 working days, delivery. Any spare parts customer need, START will arrange delivery by DHL fastly. Satisfied equipment for customers!

Test Running is the last step of machine production. After the above preparations are completed, after both parties have

confirmed and approved the design of the metal finished product and the design of the cold-formed forming machine, our production department will issue the production task list according to the customer. To complete the production and testing of the molding machine according to the industrial voltage of the country and other specific requirements of the customer, we will compare the original design and confirmed layout drawings to measure whether the finished products tested by the machine meet the requirements of the drawings, and the molding Whether the shape of the finished metal product is beautiful, whether there are burrs at the cutting place, whether the cutting speed is up to standard, whether the operation of the machine is orderly, and whether the whole process of uncoiling, leveling, forming, punching, cutting, and receiving is coordinated. Seamless,After repeated running tests, we finally deliver satisfactory equipment to customers.

Service

We provide perfect pre-sale, in-sale and after-sale service.

Pre-sale

: According to the customer's request, the engineering team will provide the layout drawings of the metal profiles, as well as the parameters of the equipment and the cost-effective equipment, and answer any questions from the customer about the equipment. During the equipment production process, we will consider the voltage and climate of the customer's country, select the appropriate electrical components, and timely feedback the production progress of the customer's equipment. From the production of the machine to the delivery to the customer's factory, we provide one-stop service, and provide installation instructions or send engineers to the customer's factory to install and guide the operation of the equipment. In the later use of the equipment, we will remind customers which parts of the equipment to maintain and mail the corresponding accessories.

In-sale

: During the production, if any problems, customer can call us and explain the situation of machine problem, with some necessary pictures and videos, we will diagnostic the causes and will support customer to solve the problems by sending customer some adjustment videos, pictures, and drawing. In this way, customer's engineer will be more and more good at the running roll forming machine, because we keep teach and share customer the key technology on roll forming machine. Besides, if customer requires, we will fly to customer's factory to give some operating instructions and training.

After-sale

: We offer 7 X 24 hours after sale service, any questions from customer about the roll forming machine, the material, the profiles, the operations, we will be feedback at the first time. By varieties of methods, such as calling, video calling, Email, SNS message, engineer go to customer's factory for visiting and checking, we can solve any problem smoothly and pursue long term cooperation!

START Mission

Our mission is very simple, to design and produce more cold-formed forming equipment that satisfies customers, let our cold-formed forming equipment spread across every country, and contribute to the urban and rural construction of each country! From de-coiler to profile cutting, Metal rollforming Systems is your trusted partner, it is simple operating, but bring you the excellent metal products. PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Cooperation

We communicate openly, support each other, and promote diversity and inclusion. Maintain long-term mutually beneficial relationships with customers and supply partners, seek common development and achieve win-win results.

Innovaton

We advocate open innovation, attach importance to user experience, and cultivate and practice new thoughts. Develop advanced technology to cope with complex application conditions and rapid changes in the market.

Responsibility

We actively advocate business civilization and professionalism. Listen to and understand customer needs and create solutions, products and services that help them succeed. Encourage employees to participate in public welfare activities and give back to the

society.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches