- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

319 KG

-

After-sales Service Provided:

-

Overseas third-party support available

-

Max. plate size:

-

100*250mm

-

color:

-

green

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LC

-

Voltage:

-

110/220v 60/50Hz 1 PHASE

-

Weight:

-

319 KG

-

After-sales Service Provided:

-

Overseas third-party support available

-

Max. plate size:

-

100*250mm

-

color:

-

green

-

After Warranty Service:

-

Video technical support

6-color pad printing machine with conveyer

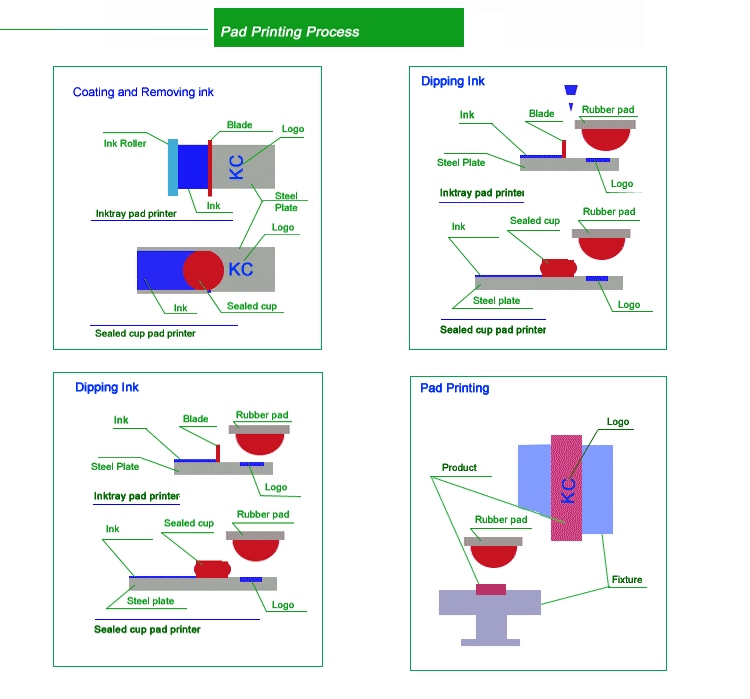

Pad printing machines, like silk screen printing machines, must have complete printing consumables to print. When you get the product to be printed and consult with the supplier, you must fully understand the technical details involved in the pad printing machine:

1) Pad printing plates: Pad printing machines use thick steel plates, thin steel sheets and resin plates. In European countries, resin plates are preferred. When operating pad printing machines, the printing pattern must be printed on the printing plates. How to make printing plates? version is also a specialized technology

2) Pad printing ink: Pad printing ink is related to the material of the product, and the general supplier will test it when you provide samples;

3) Pad printing pad: The shape of the pad printing pad is related to the printing pattern of the product, and suppliers have a wide variety of pad printing pads to choose from;

4) Fixtures: In addition to paper and fabric, most products need to make corresponding fixtures to fix the products.

Users who have purchased an oil cup pad printing machine should also consider whether to use a steel ring or a ceramic ring.

| SPM6-150/20T Six colours pad printer with 18station conveyor | |

| Working table type | 20-stations conveyer-type working table |

| Ink supply system | Sealed cup |

| Standard plate type and size | 10mm Thickness steel plate, 100*250mm. |

| Transport stroke | 125mm |

| Colour Number | 6 |

| Rubber pad of dropping control | Simple-cylinder drive |

| Usage | Electrons,hardwares, autos, toys, gifts, Plastics, household appliances, artware, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, ect, industrial field. |

| Application |

SP6-150/20T Six colours Sealed cup pad printer with conveyer :

Print both one colour to six colours with conveyer worktable, Printing speed is more precision. With sealed cup to store ink, saving ink and proenvironment protection ; With coin aluminium structure ensure more stabilization and long life. Independent sealed cup driving device, Ink removing completely . Make min Pressure to remove ink ; Can print almost small size objects . so sold very nice in the world. Widely used in the industry field of cosmetics case, electron parts, Toys, plastics production, Houseware,gifts, decorations. Completely printing solution including ink and thinner , fixtures, steel plates, rubber pads provided when you send us samples to send. Max Plate size: 100*250mm. Conveyer stroke: 125mm. 20 stations on working table. |

| Specifications |

SPM6-150/20T Six colours sealed cup pad printer with 18-station conveyer

1.Max. plate size: 100×250mm 2.Max. worktable area: 70x100mm 3.Sealed cup diameter: Φ90mm 4.Max. printing speed: 600pcs/h 5.Printable colours:6 6.Max print area: 80mm×130mm; 7.Station number: 20pcs 8. Max Products Dimension: 120×230mm. 9. Table stroke: 125mm |

| Advantages |

1. Six color printing with conveyer;

2. Microprocessor control with numerical display leads to easy operation; 3. Automatic 5-digit counter installed; 4. With aluminum alloy frame, the machine is light and sturdy ; 5. The speed and the vertical stroke of the pad can be adjusted independently; 6. With sealed cup to protect operating environment; 7. The extra function "twice inking, once printing" is designed for thicker ink film; 8. For different requirements, the working speed can be adjusted; 9. Sweeps forward and backward without pad falling down, to prevent ink drying; 10.6-color, 3-color, 2-color, 1-color printing available, 11.The ink cup can be independently adjusted for overprint; 11.With air jet for fast drying; |

Details

1. What is a pad printer ?

Pad printing machine is the machine, which uses an indirect printing process, it is very suitable for printing irregular surface of small products, make up for the lack of screen printing process, known as the screen printing twin sisters .

2 . The difference between the closed cup pad printer and open inkwell pad printer

The open ink-tray pad printer uses the ink-tray as the ink supply way, the ink is exposed to the air, the VOC is easy to volatilize to cause the air pollution, the ink-tray pad printers sells mainly to China, Asia, Africa and Eastern Europe and so on the environmental pollution request is not Too high a country;

The closed cup pad printer uses the closed cup as the ink supply way, the ink is enclosed in the cup, the VOC can not volatilize to the air, does not have the pollution to the environment basically, the closed cup pad printers sells mainly to Western Europe, On the environment demanding countries and regions.

3. Shuttle pad printer and Turntable pad printer

Shuttle pad printer is installed shuttle table printing machine, printing back and forth between the colors in the printing, shuttle printing machine can only print one product at a time, more accurate overprint, slower; and Turntable pad printer is installed Rotary table of the printing machine, a 10-station, 16-station, 22-station in various forms. Turntable pad printing machine stations are required to install the same product for printing, faster, no printing shuttle printing machine accurate.

4. Pad printing machine operating system

The ordinary printing machine adopts the microcomputer control system to carry on the control, the high-end pad printing machine uses the PLC to carry on the control, specially the servo control system pad printing machine or the automatic pad printing machine, uses the PLC control system quite commonly.

5. Pad printing machine movement characteristics

Most of the pad printing machine pneumatic control, slower, low cost. With the printing quality and printing speed of the user's high demand in recent years, the use of mechanical control of the pad printing machine more and more common. Pad printing machine automation is the most distinctive trend, the use of automatic feeding system, prepress processing device, servo drive system, automatic printing, drying machine as one of the mechanical and pneumatic motion perfect combination, greatly improving the productivity.

6. How to evaluate the quality of the pad printer

Pad Printing machine technology content is low, more and more enterprises began to produce and sell pad printing machines, pad printing machines of uneven quality, how to evaluate the quality of pad printing machine is essential. As the majority of brand-name pad printing machine is not sold through the network, so, through Alibaba sales of pad printing machines are low-end pad printing machine.

1) Design of the factory means: a special design department of the enterprise quality is more reliable. China has 70% of the pad printing machine manufacturing enterprises and no special design department, the development of new products on-site assembly by the basic, which is extremely adverse to the standardization of production machinery;

2) Processing means: CNC processing costs are higher, but the parts manufactured high precision; visit the factory must inspect whether the factory has CNC machining capacity;

3) Materials Selection: Material selection is very important. Now fierce competition, the vast majority of domestic factories in the selection of the above efforts, only the brand enterprises are willing to insist on the selection criteria above;

7. What is pad plate of pad printer?

8. How to make rubber pad of pad printer?

9. What is fixture of pad printer?

10.How to judge number color of pad printer?

11. How to choose pad printing ink?