- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

1800 mm

-

Dimension:

-

4500x2300x3450

-

Place of Origin:

-

China

-

Year:

-

2022

-

Weight (KG):

-

26000

-

Motor Power (kw):

-

30 kw

-

Product name:

-

Sheet metal press brake

-

Keyword:

-

Brake Press Machine

-

Application:

-

Stainless Plate Bending

-

Name:

-

Hydraulic Bending Machine

-

Material:

-

Sheet Metal/carbon steel

-

Function:

-

Metal bender

-

Control system:

-

E21/DElEM/CYBELEC

-

Voltage:

-

380V/50HZ/3PH

-

Bending Material:

-

CS/SS/Mild steel/copper

-

Type:

-

Press brake machine for sheet metal bending with E21

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

4000

-

Slider Stroke (mm):

-

250 mm

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

1800 mm

-

Dimension:

-

4500x2300x3450

-

Place of Origin:

-

China

-

Year:

-

2022

-

Weight (KG):

-

26000

-

Motor Power (kw):

-

30 kw

-

Product name:

-

Sheet metal press brake

-

Keyword:

-

Brake Press Machine

-

Application:

-

Stainless Plate Bending

-

Name:

-

Hydraulic Bending Machine

-

Material:

-

Sheet Metal/carbon steel

-

Function:

-

Metal bender

-

Control system:

-

E21/DElEM/CYBELEC

-

Voltage:

-

380V/50HZ/3PH

-

Bending Material:

-

CS/SS/Mild steel/copper

-

Type:

-

Press brake machine for sheet metal bending with E21

Product Introdution

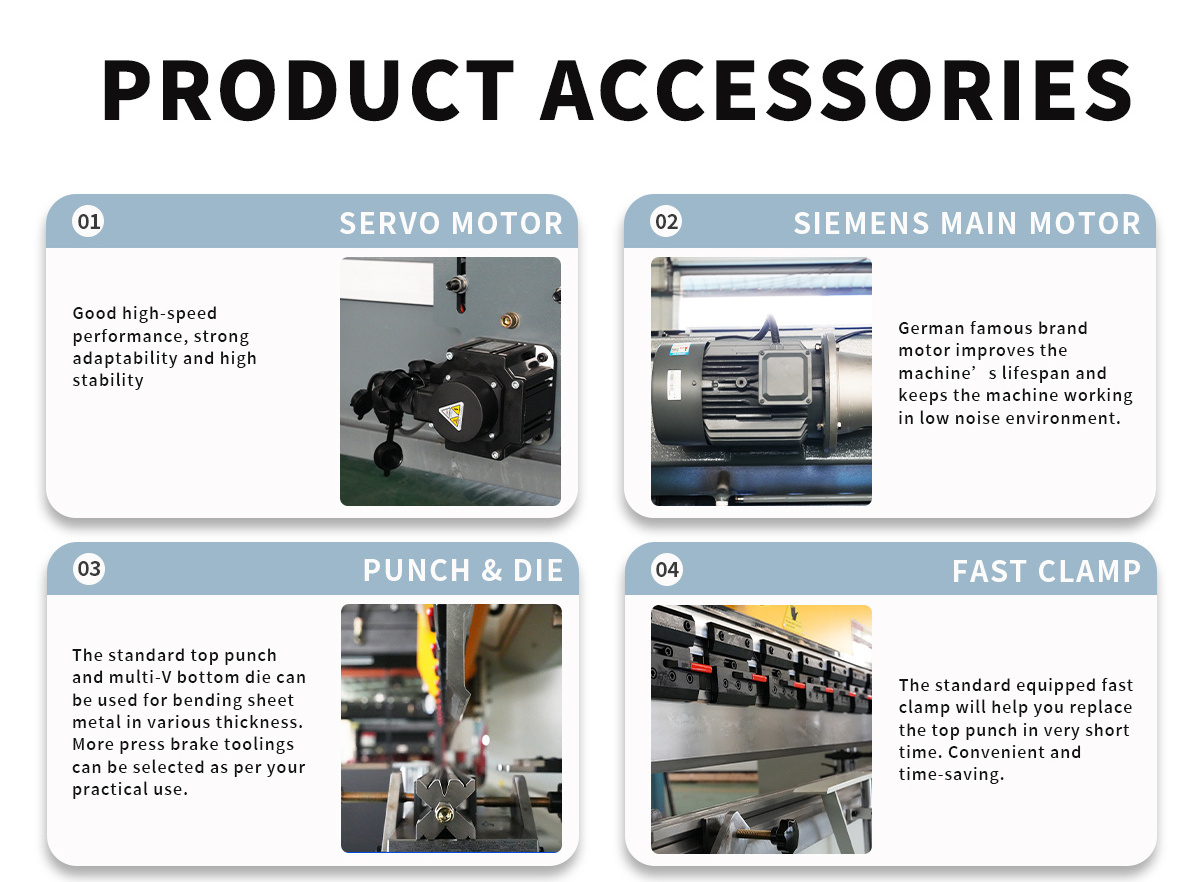

FEATURES

* OVERALL WELDED AND PROCESSED STRUCTURE.

* MECHANICAL STOP AND STEEL TORSION BAR TO MAINTAIN SYNCHRONIZATION AND HIGH PRECISION.

* MOVEMENT OF BACKGAUGE AND RAM STROKE IS SERVO CONTROLLED BY CONTROLLER

* THE FUNCTION OF ANGLE PROGRAMMING OF CONTROLLER WILL BRING HIGH BENDING EFFICIENCY.

* X AXES AND Y AXES ARE CONTROLLED BY SERVO MOTOR, WITH STRONG SYNCHRONOUS BELT, WITH HIGH CONTROL ACCURACY, FAST POSITIONING AND LOW NOISE.ALSO WITH ELECTRIC R AXES

* WITH IMPORTED HYDRAULIC SYSTEM,STABLE AND HIGH PRECISION WHEN PERSISTENT WORKING.

* IMPORTED BALL BEARING LEAD SCREW AND LINEAR GUIDE RAIL ARE USED FOR REAR STOPPER, TO ENSURE THE POSITIONING PRECISION OF REAR STOPPER, FOR PROCESSING PRECISION OF MACHINE TO BE HIGHER

* OVERALL WELDED AND PROCESSED STRUCTURE.

* MECHANICAL STOP AND STEEL TORSION BAR TO MAINTAIN SYNCHRONIZATION AND HIGH PRECISION.

* MOVEMENT OF BACKGAUGE AND RAM STROKE IS SERVO CONTROLLED BY CONTROLLER

* THE FUNCTION OF ANGLE PROGRAMMING OF CONTROLLER WILL BRING HIGH BENDING EFFICIENCY.

* X AXES AND Y AXES ARE CONTROLLED BY SERVO MOTOR, WITH STRONG SYNCHRONOUS BELT, WITH HIGH CONTROL ACCURACY, FAST POSITIONING AND LOW NOISE.ALSO WITH ELECTRIC R AXES

* WITH IMPORTED HYDRAULIC SYSTEM,STABLE AND HIGH PRECISION WHEN PERSISTENT WORKING.

* IMPORTED BALL BEARING LEAD SCREW AND LINEAR GUIDE RAIL ARE USED FOR REAR STOPPER, TO ENSURE THE POSITIONING PRECISION OF REAR STOPPER, FOR PROCESSING PRECISION OF MACHINE TO BE HIGHER

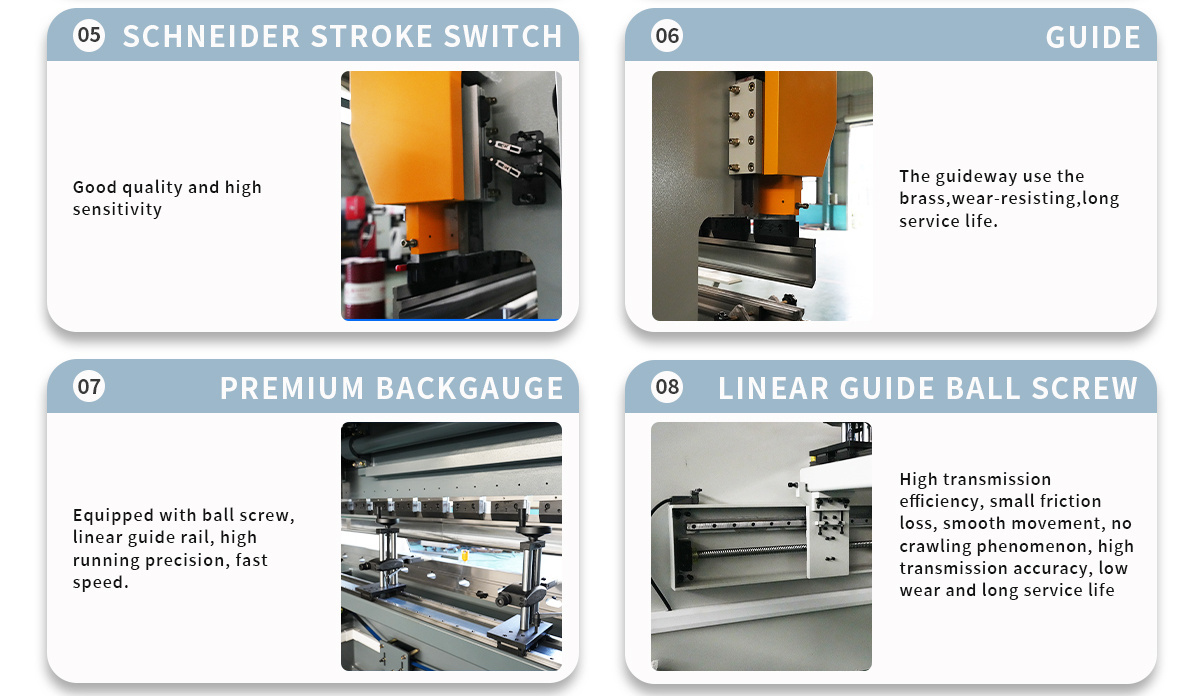

Standard Configuration

1. Siemens Main Motor Germany Brand

2. Rexroth Hydraulic System

3. Schneider Stroke Switch

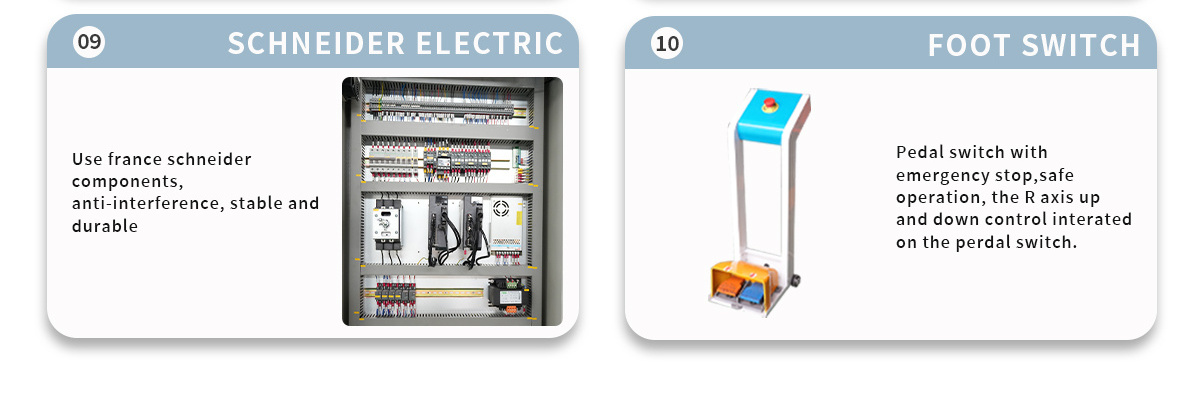

4. Use France Schneider components,anti-interference,stable and durable

5. Pedal switch with emergency stop,safe operation,the R axis up and down control integrated on the pedal switch

6. The torsion bar is synchronized with the gear rack.Easy to adjust the two sides of the synchronization.The connector use wear-resistant brass

7. The guideway use the brass,wear-resisting,long service life

8. Galvanized cold drawn tube,Germany connector

2. Rexroth Hydraulic System

3. Schneider Stroke Switch

4. Use France Schneider components,anti-interference,stable and durable

5. Pedal switch with emergency stop,safe operation,the R axis up and down control integrated on the pedal switch

6. The torsion bar is synchronized with the gear rack.Easy to adjust the two sides of the synchronization.The connector use wear-resistant brass

7. The guideway use the brass,wear-resisting,long service life

8. Galvanized cold drawn tube,Germany connector

Specification

|

Item

|

Unit

|

6325

|

10032

|

10040

|

12532

|

12540

|

16032

|

16040

|

20032

|

|

Capacity

|

KN

|

630

|

1000

|

1000

|

1250

|

1250

|

1600

|

1600

|

2000

|

|

Table Length

|

mm

|

2500

|

3200

|

4000

|

3200

|

4000

|

3200

|

4000

|

3200

|

|

Between Columns

|

mm

|

2100

|

2600

|

3100

|

2600

|

3100

|

2600

|

3100

|

2600

|

|

Daylight Opening

|

mm

|

420

|

460

|

460

|

460

|

460

|

460

|

460

|

460

|

|

Ram Stroke

|

mm

|

150

|

200

|

200

|

200

|

200

|

200

|

200

|

200

|

|

Throat Depth

|

mm

|

320

|

400

|

400

|

400

|

400

|

400

|

400

|

400

|

|

Approach Speed

|

mm/s

|

180

|

180

|

180

|

180

|

180

|

160

|

160

|

150

|

|

Working Speed

|

mm/s

|

12

|

10

|

10

|

10

|

10

|

9

|

9

|

9

|

|

Return Speed

|

mm/s

|

170

|

160

|

160

|

160

|

150

|

150

|

140

|

140

|

|

Main Motor Power

|

kw

|

5.5

|

7.5

|

7.5

|

7.5

|

7.5

|

11

|

11

|

15

|

|

X axes stroke

|

mm

|

500

|

500

|

500

|

500

|

500

|

500

|

500

|

500

|

|

X axes speed

|

mm/s

|

300

|

300

|

300

|

300

|

300

|

300

|

300

|

300

|

|

R axes stroke

|

mm

|

200

|

200

|

200

|

200

|

200

|

200

|

200

|

200

|

Our campany

Hot Searches