- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DEYI

-

Voltage:

-

380V

-

Power:

-

80000

-

Dimension(L*W*H):

-

75000X20000X2500MM

-

Weight:

-

30000 kg

-

Marketing Type:

-

New Product 2024

-

Raw material:

-

Waste Paper

-

Color:

-

Customized Color

-

Type:

-

Packaging Line

-

Fuel:

-

Natural Gas

-

Drive way:

-

Electric Motor

Quick Details

-

Production Capacity:

-

3800-4000 piece/hour

-

Processing Type:

-

Other, Pulp Molding Machine

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DEYI

-

Voltage:

-

380V

-

Power:

-

80000

-

Dimension(L*W*H):

-

75000X20000X2500MM

-

Weight:

-

30000 kg

-

Marketing Type:

-

New Product 2024

-

Raw material:

-

Waste Paper

-

Color:

-

Customized Color

-

Type:

-

Packaging Line

-

Fuel:

-

Natural Gas

-

Drive way:

-

Electric Motor

Product Description

Longkou DEYI Mechanical Equipment Co, Ltd,

established in 1980. is a SINO-ITALY joint venture with advanced leading technology We specialize in manufacturing the following products: Plastic Foaming Machine, Packing Machinery, Pulp Moulding Machinery more than 30 years experiences. Our enterprise management concept is based on innovation, excellent quality and skilled workmanship. We are enjoying a good reputation through over 100 countries and areas and have got customers' trust deeply.Moreover, our sales volume of foaming machine is No.1 compared with other Chinese suppliers. We sincerely hope to cooperate with friends from and abroad and help you succeed with our profession.

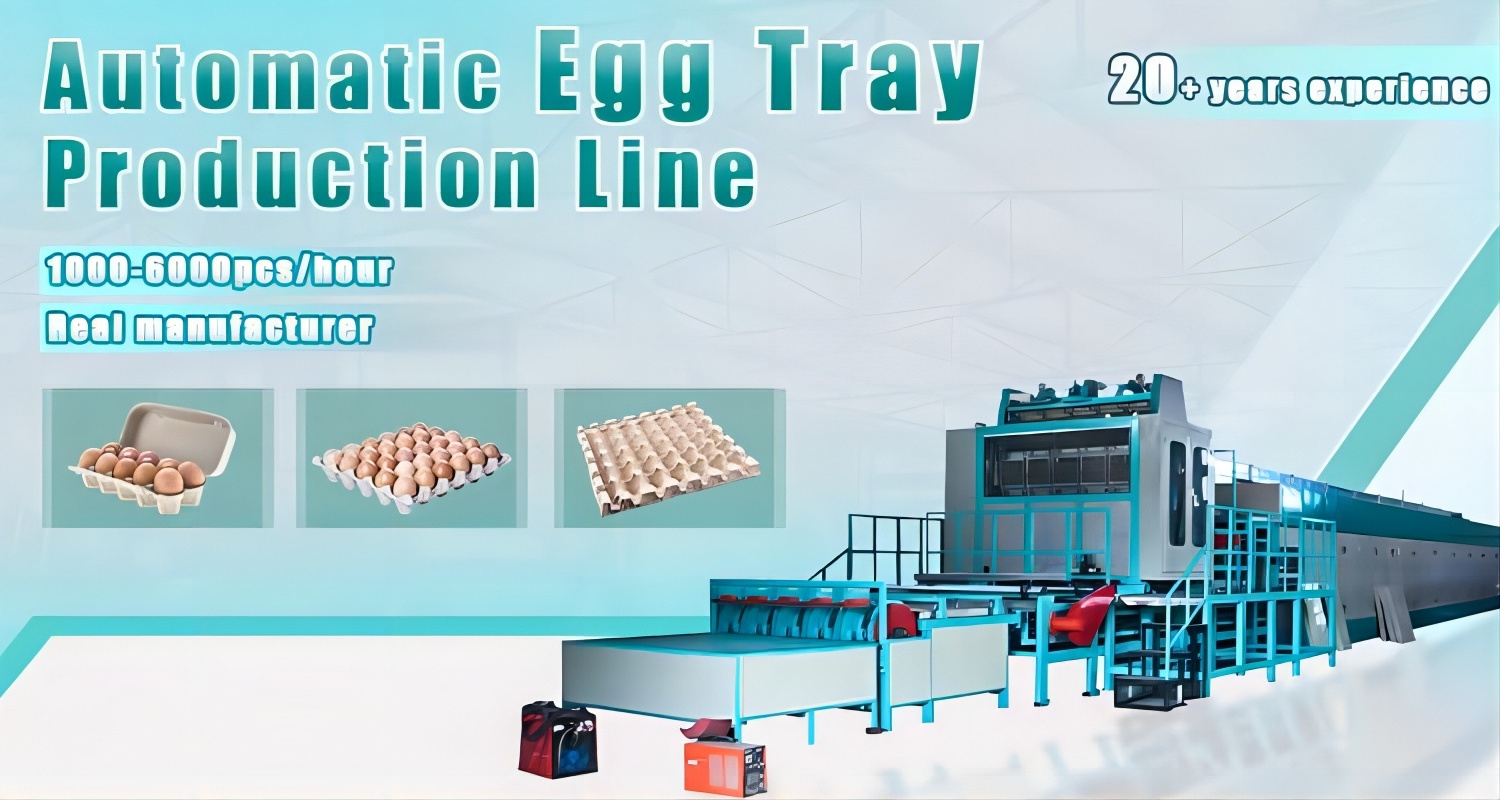

Fully Automatic waste paper recycle used egg tray machine/paper egg tray forming machine/large machine making egg tray

This automatic egg tray machine is suitable for every kind of scale production plants. It can produce egg tray, egg boxes and other shapes of tray. Its output is 6000pcs/h for 30 cavity trays, so it can allow workers to work three shifts per day. The product can be recycled, is a new green packaging, which is not only the development of environment-friendly enterprise, also long get rich choice.

|

Machine Model

|

|

|

|

|

||||

|

Machine Model

|

DY-1200

|

DY-3000

|

DY-5000

|

DY-6000

|

||||

|

Capacity (pcs/h)

|

1200

|

2000-3000

|

4000-5000

|

6000

|

||||

|

Machine parameter

|

|

|

|

|

||||

|

Equipment parameter

|

|

1-1.5T/hr

|

|

|

||||

|

Raw material

|

|

1000kgs/hr

|

|

|

||||

|

Electricity

|

|

239.5kw/hr

|

|

|

||||

|

Natural gas

|

|

40m³/hr

|

|

|

||||

|

Diesel oil

|

|

36kgs/hr

|

|

|

||||

|

Worker

|

|

5 person/shift

|

|

|

||||

|

Total power

|

|

About 120KWh--130KWh per hour

|

|

|

||||

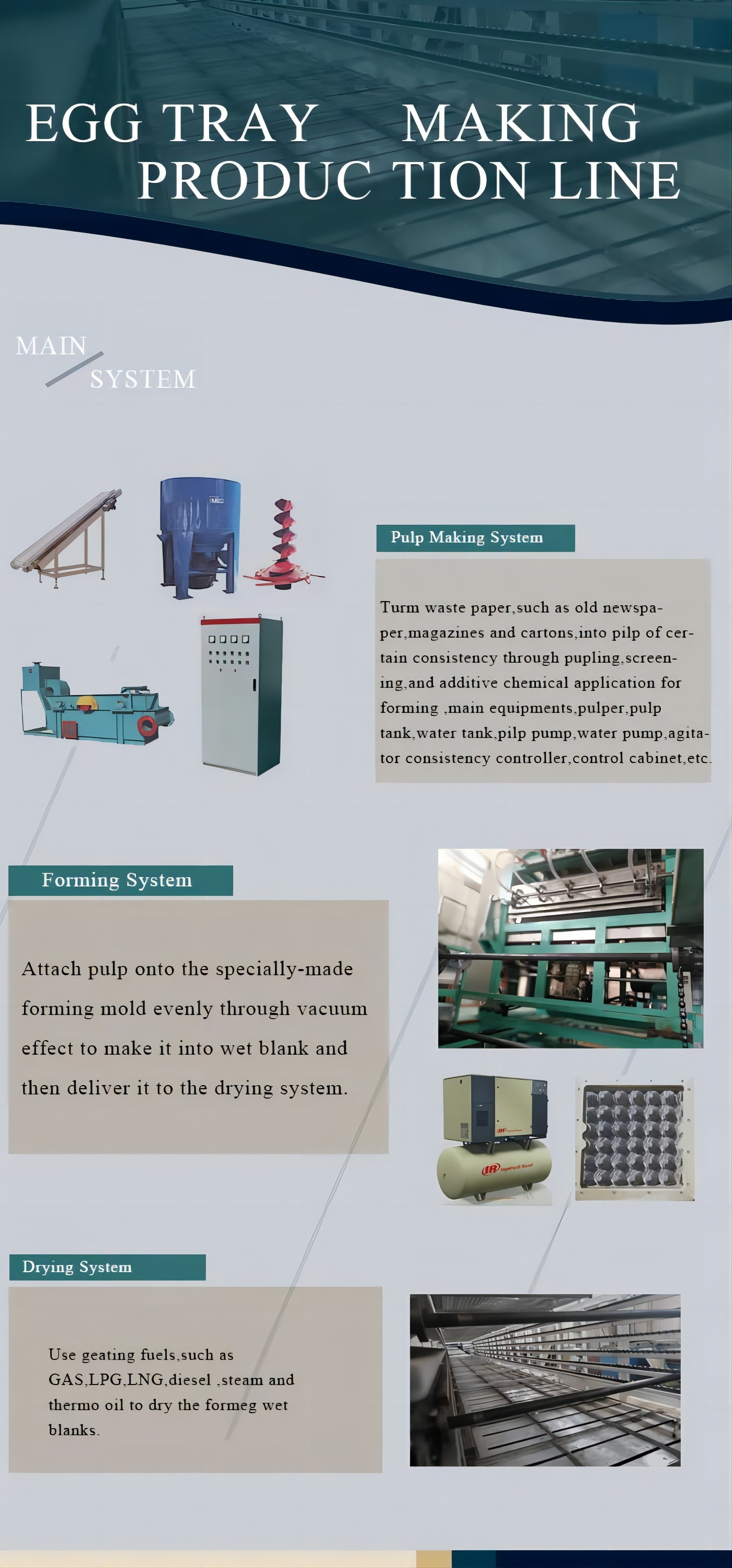

Detailed information

Self-priming pump

Power:5.5kw

Usage: removal the water of vacuum tank

Usage: removal the water of vacuum tank

Drying systerm

Use geating fuels, such as diedel oil, coal, LPGS, GAS, etc to dry the formeg wet blanks.

Pulper

Auto feeding and auto give water.

Material:carbon steel Power :45kw

Capacity :5m³

Material:carbon steel Power :45kw

Capacity :5m³

Forming machine

The parts connected with pulp are all 304# stainless steel

Capacity :6000pcs/h

5molds*8faces

Power:15.5kw

With automatic oil feeding system and automatic cleaning

mould

Capacity :6000pcs/h

5molds*8faces

Power:15.5kw

With automatic oil feeding system and automatic cleaning

mould

Finished Product Photo

Flow chart

Installation Instructions

The flowing items must be prepared by the buyers before installation:

The pulp tank, water tank and draining system should be built of reinforced concrete. Buyer is responsible to guarantee the power and water supply to make sure equipment and controlling cabinets can work normally.

All necessary craft pipelines (if you can provide your factory area, we can design all pipelines free of charge) and valve,

electric wires, cable, wire slots, bracket and so on. Above should be prepared in advance.

All necessary craft pipelines (if you can provide your factory area, we can design all pipelines free of charge) and valve,

electric wires, cable, wire slots, bracket and so on. Above should be prepared in advance.

Packing & Delivery

FAQ

Q:Why are many pictures on the Internet the same as your company?

A:Because our company has been specialized in pulp manufacturing machinery for more than 30 years, after years of exploration and continuous research, the appearance of the equipment and the ease of use have led the Chinese pulp manufacturing machinery industry,it is inevitable to be stolen by competitors, but our core technology is not something that everyone can learn.

Q:Why I choose your company?

A:a) We are the Leading puple making machine Manufacturer in China.

b) We have made pulp manufacturing machine about 30 years with strong experience and advanced technics.

c) Best Quality & Best Service with Competitive price.

d) 100% inspection Before Shipment, and got CE certificate.

e) We have Professional technical team, supply 24 hours service

A:Because our company has been specialized in pulp manufacturing machinery for more than 30 years, after years of exploration and continuous research, the appearance of the equipment and the ease of use have led the Chinese pulp manufacturing machinery industry,it is inevitable to be stolen by competitors, but our core technology is not something that everyone can learn.

Q:Why I choose your company?

A:a) We are the Leading puple making machine Manufacturer in China.

b) We have made pulp manufacturing machine about 30 years with strong experience and advanced technics.

c) Best Quality & Best Service with Competitive price.

d) 100% inspection Before Shipment, and got CE certificate.

e) We have Professional technical team, supply 24 hours service

Hot Searches