- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1000*1000*1000

-

Weight (T):

-

5 T

-

Power (kW):

-

80

-

Fuel:

-

Electeric

-

Application:

-

Annealing

-

After-sales Service Provided:

-

Engineers, Free spare parts, Field installation, commissioning and training, Video technical support, Online support

-

Feature:

-

High Efficiency

-

Furnace type:

-

Treatment Furnace

-

Phase:

-

3

-

Rated frequency:

-

500 HZ

-

Rated voltage:

-

380V

-

Rated power:

-

80kw

-

Rated temperature:

-

1100℃

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Henan, China

-

Core Components:

-

PID

-

Brand Name:

-

RXS

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1000*1000*1000

-

Weight (T):

-

5 T

-

Power (kW):

-

80

-

Fuel:

-

Electeric

-

Application:

-

Annealing

-

After-sales Service Provided:

-

Engineers, Free spare parts, Field installation, commissioning and training, Video technical support, Online support

-

Feature:

-

High Efficiency

-

Furnace type:

-

Treatment Furnace

-

Phase:

-

3

-

Rated frequency:

-

500 HZ

-

Rated voltage:

-

380V

-

Rated power:

-

80kw

-

Rated temperature:

-

1100℃

-

Certification:

-

CE

Furnace shell

The furnace shell will be fabricated out of 4/5/12/20mm thick sheet of Q235 steel plate adequately reinforced with suitable size of angle and channel giving rigid strength to the mechanical structure.

We adopt continuous tight welding and rivet welding.

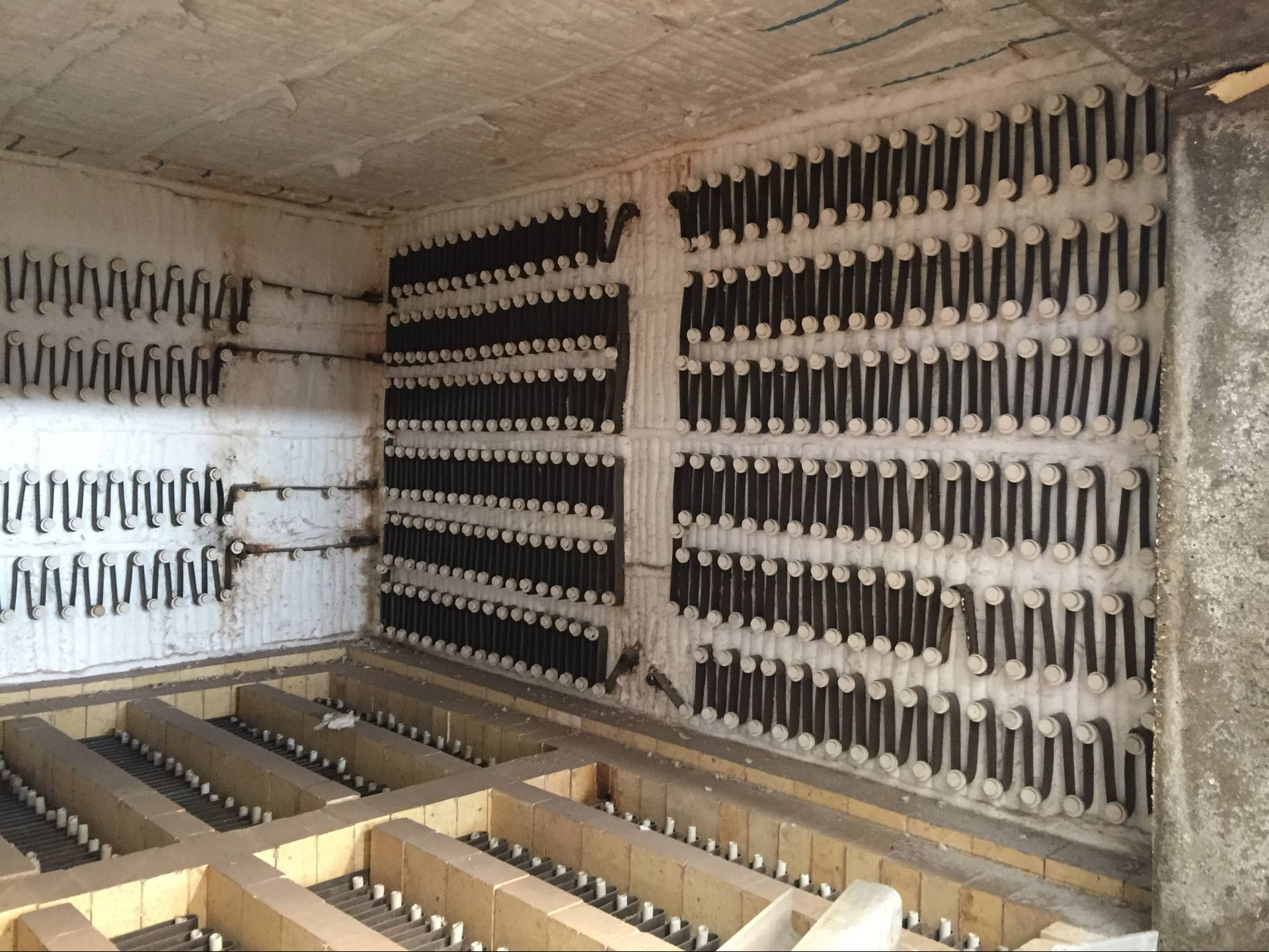

Furnace lining

The furnace lining is boned 300mm thick ceramic fiber block and 20mm thick aluminum ceramic fiber and blanket to resist the high temperature. Our insulation material is LUYANG, SHANDONG with excellent insulation effect.

The total thick of the insulation layer is:330mm.

And the fixing anchor can resist temperature 1300℃.

The installation method is side-by-side configuration in four sides and top of furnace, and using anchoring to fix it.

Refractory fiber has the following advantages:

1)light weight (about 1/10 of the refractory brick)

2)very low coefficient of thermal conductivity

3)Excellent heat insulation, fire prevention, sound-absorbing

4)Heat up fast

5)Low hot melting

6)good heat preservation performance

7)Good thermal shock performance

8)Good tensile strength

9)Excellent thermal stability and thermal shock resistance

10)Long service life, energy saving, convenient maintenance, etc.

Furnace door

It includes furnace door, lifting device, and furnace door pressing device.

The door frame will be manufacture with 10/12mm thick sheet of Q235 steel plate and then install insulation material.

The furnace door is closed and open by electric lifting device with reducer, the lifting speed: 6-8m/min.

There are mechanical limit and electrical limit for furnace up and down. The driving device of the lifting device is installed at the furnace door beam, easy to maintain.

Trolley

1. Trolley steel structure: Welding with Q235 steel plate

2. Trolley insulation structure: The 1 layer is 10mm Calcium silicate board insulation layer, then one layer of lightweight insulation brick insulating layer , one layer of Mullite firebrick, refractory layer is built by clay load-bearing brick, and the refractory layer is layed with heating element .

3. Trolley drive structure: the trolley is driven by 1 reducer, power 1.1 kw. There are 2 sets of wheels group, wheel diameter:300mm.

4. Trolley sealing: Two sides of furnace body--We adopt double inserted sealing form.

5. Bogie hearth plate mat erial : ZG40Cr2 5Ni20

The rotation device mainly consist of hydraulic cylinder

The furnace trolley bottom has 2 layers of plate, to achieve tilting of the trolley for fast quenching.

Heating element

Type: 0Cr21Al6Nb (Brand: Beijing shoudu steel)

Material : Electrothermal alloy

Connection rod: 0Cr21Al6Nb

T emperature and electric control system

Standard control cabinet-1 pcs

Furnace door and trolley control system-- Interconnected control and sealing control

Alarm control system

Thermocouple& compensating lead wire—K type ,1 pec

Intelligent temperature control instrument-- PID control system

Solid-state relay—SHIMADEN

Temp. controller — AI518P, 1 p ec

Temp. recorder — AI3702,1 p ec