- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WingsPlastic

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

25000mm 2000mm 2500mm

-

Power (kW):

-

40

-

Weight:

-

3000 KG

-

Motor:

-

China Top Brand

-

Inverter:

-

Delta Brand

-

Temperature controller:

-

Omron Brand

-

Contactor:

-

Siemens Contactor

-

switch:

-

CHNT

-

After Warranty Service:

-

Video technical support

-

Marketing Type:

-

New Product 2020

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

22:1

-

Screw Speed (rpm):

-

35 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WingsPlastic

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

25000mm 2000mm 2500mm

-

Power (kW):

-

40

-

Weight:

-

3000 KG

-

Motor:

-

China Top Brand

-

Inverter:

-

Delta Brand

-

Temperature controller:

-

Omron Brand

-

Contactor:

-

Siemens Contactor

-

switch:

-

CHNT

-

After Warranty Service:

-

Video technical support

-

Marketing Type:

-

New Product 2020

Product Description

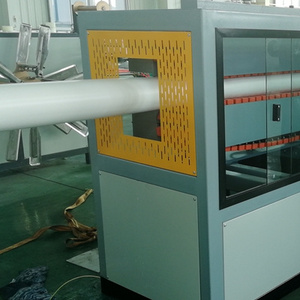

CPVC UPVC Rigid Water Electric pvc pipe machine extruder plastic pipe machine pvc pipe machine making 20-110mm

PVC Pipe Machine

extruder plastic pipe machine

pvc pipe machine making 20-110mm

pvc pipe making machine

pvc pipe machine price

pvc pipe machine making 20-110mm

SJSZ series plastic extruder/ extrusion machine are special equipments which can extrude and mold by using various kinds PVC

powders. Equipped with different kinds of molds and auxiliary machines, it can produce various PVC pipe diameters.PVC series pipes are mainly used for agricultural water supply system, sewer system, waters discharge systems for civil and industrial buildings,cable conduits, protection sheathing for electric cables, etc.PVC Series pipe solution, equipped with new design high-efficiency twin-screw conical extruder, which is high speed high efficiency; Reasonable flow channel design, accurate melting temperature control; planetary non-dust cutting, uniform chamfering.

SJSZ series plastic extruder/ extrusion machine are special equipments which can extrude and mold by using various kinds PVC

powders. Equipped with different kinds of molds and auxiliary machines, it can produce various PVC pipe diameters.PVC series pipes are mainly used for agricultural water supply system, sewer system, waters discharge systems for civil and industrial buildings,cable conduits, protection sheathing for electric cables, etc.PVC Series pipe solution, equipped with new design high-efficiency twin-screw conical extruder, which is high speed high efficiency; Reasonable flow channel design, accurate melting temperature control; planetary non-dust cutting, uniform chamfering.

PVC one cavity production line

Φ20-Φ630 series PVC pipe extrusion machine line is mainly used in the manufacture of plastic PVC pipes with various diameters and wall thickness used in the industries such as agricultural and constructional plumbing,cable laying etc. This line is composed of

conical twin screw extruder,Vacuum calibration tank,haul off,motors,cutter and stacker etc. The extruder and haul off methods are

two-claw,three-claw four-claw,six-claw,eight-claw,ten-claw,twelve claw etc. You may choose saw blade cutting type or planetary

cutting type. It is additionaly attached with length counter and intensifying device. This line with reliable performance and high

production efficiency. Our company can also manufacture special pipe production lines,e.g. spiral silencing pipe and core foaming

pipe according to your requirements.

PVC double-pipe production line

The production line is developed with the advanced technology of west Europe by our company. The main machine is SJSZ55/120 or SJSZ65/132 conical twin screw extruder is equipped with double-tube single control stainless steel spraying calibration,it avoids

waste condition when one tube is adjusted and the other one is affected. The auto single-control double drawing machine and cuting

machine are combined with the front double calibration technology to make operation more flexible let you enjoy economic benefit

which is brought by separate-control double tube extruding.

PVC four cavity production line

Four cavity PVC electrical tube,water supply pipe extrusion line can extruder four pipes at same time on one machine.This line can

save investment cost in factory building and production,which increase the capacity a lot and reduce production time.SJSZ65

conical twin-screw extruder can easily reach 5.5-6.5 ton/per day,the production speed take 16mm as example can get more than

8-10m/min.The whole line is composed of conical twin-screw extruder 65mm,4 cavity mould,4 cavity coling calibration tank,4 station haul off,4 station cutter and 4 station tipping table.

Φ20-Φ630 series PVC pipe extrusion machine line is mainly used in the manufacture of plastic PVC pipes with various diameters and wall thickness used in the industries such as agricultural and constructional plumbing,cable laying etc. This line is composed of

conical twin screw extruder,Vacuum calibration tank,haul off,motors,cutter and stacker etc. The extruder and haul off methods are

two-claw,three-claw four-claw,six-claw,eight-claw,ten-claw,twelve claw etc. You may choose saw blade cutting type or planetary

cutting type. It is additionaly attached with length counter and intensifying device. This line with reliable performance and high

production efficiency. Our company can also manufacture special pipe production lines,e.g. spiral silencing pipe and core foaming

pipe according to your requirements.

PVC double-pipe production line

The production line is developed with the advanced technology of west Europe by our company. The main machine is SJSZ55/120 or SJSZ65/132 conical twin screw extruder is equipped with double-tube single control stainless steel spraying calibration,it avoids

waste condition when one tube is adjusted and the other one is affected. The auto single-control double drawing machine and cuting

machine are combined with the front double calibration technology to make operation more flexible let you enjoy economic benefit

which is brought by separate-control double tube extruding.

PVC four cavity production line

Four cavity PVC electrical tube,water supply pipe extrusion line can extruder four pipes at same time on one machine.This line can

save investment cost in factory building and production,which increase the capacity a lot and reduce production time.SJSZ65

conical twin-screw extruder can easily reach 5.5-6.5 ton/per day,the production speed take 16mm as example can get more than

8-10m/min.The whole line is composed of conical twin-screw extruder 65mm,4 cavity mould,4 cavity coling calibration tank,4 station haul off,4 station cutter and 4 station tipping table.

Features of our machine PVC Pipe Making Machine:

PVC electrical conduit pipe extrusion line is used to produce pvc electric conduit pipe with diameter from 16 to 63mm, which are

flexible, bendable in the aspect of electric wire protecting.

Capacity: Conical twin-screw extruder, suitable for process PVC powder with high capacity

Diameter: Friend machinery succeed in designing and producing the biggest conical twin-screw extruder in the world.

Auxiliary machine closely meet customer specifications. Nice apperance, automatic control and stable running performance.

PVC electrical conduit pipe extrusion line is used to produce pvc electric conduit pipe with diameter from 16 to 63mm, which are

flexible, bendable in the aspect of electric wire protecting.

Capacity: Conical twin-screw extruder, suitable for process PVC powder with high capacity

Diameter: Friend machinery succeed in designing and producing the biggest conical twin-screw extruder in the world.

Auxiliary machine closely meet customer specifications. Nice apperance, automatic control and stable running performance.

Key Words:

PVC Pipe Machine extruder plastic pipe machine pvc pipe machine making 20-110mm

|

Item

|

SJZ51/105

|

SJZ55/110

|

SJZ65/132

|

SJZ80/156

|

SJZ92/188

|

|

Diameter of screw

|

51/105mm

|

55/110mm

|

65/132mm

|

80/156mm

|

92/188mm

|

|

Main Motor

|

22kw

|

30kw

|

37kw

|

55kw

|

90/110kw

|

|

Max capacity

|

120kg/h

|

180kg/h

|

300kg/h

|

500kg/h

|

900kg/h

|

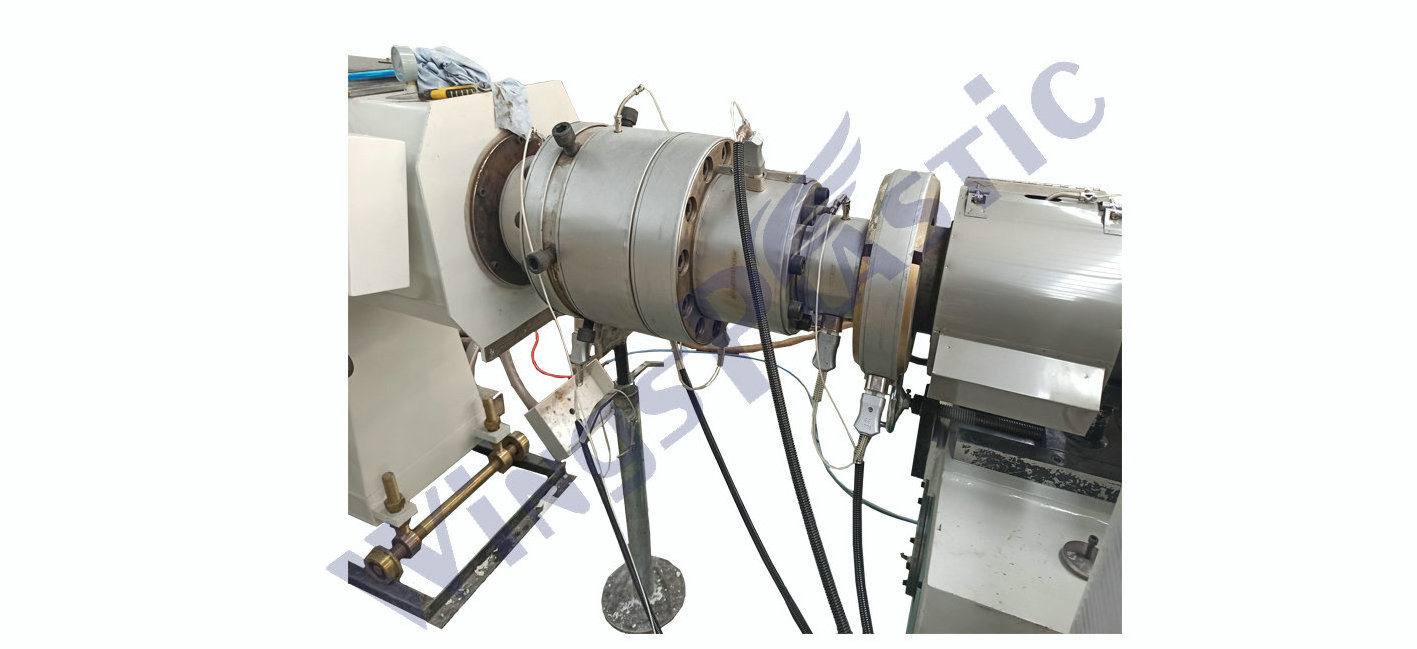

Twin screw extruder

High production capacity of extrusion on the high quality basis. Lower temperature plasticizing design, ensure high quality pipe extrusion. Material of screw and barrel: 38CrMoAlA, nitrogen quenched (0.4-0.7mm ), Rigidity of screw: >740 , Rigidity of barel>940, the surface of screw is chromeplated Feeding bush with water cooling system

Pipe Extrusion Die head

The die head is made by 40Cr moulds materials.

Using mica heating way

Using mica heating way

Pipe Vacuum Tank

It is adopted stainless steel materials, high quality vacuum and water pumb. There is flow stabilization system for better pipe surface.

Haul off unit

It is rubber block clamping way.

2 claw, 3 claw, 4 claw ,6 claw, 8 claw, 12 claw made according pipe diameters.

2 claw, 3 claw, 4 claw ,6 claw, 8 claw, 12 claw made according pipe diameters.

Cutting Machine

It could be no dust cutting,planetary cutting,chamfer cutting,saw cutting according customer reques

Stacker

Length 6000mm

Stacking way:Pneumatic way

Stacking way:Pneumatic way

Mixer

It is working for mixing pvc powder materials with additives according formula.

It could be 200/500mixer,300/600mixer,500/1000mixer always.

It could be 200/500mixer,300/600mixer,500/1000mixer always.

Electric Control Unit

Switch and Button brand:CHNT/Schneider

Temperature Controller:Omron

Inverter:Siemens/ABB/Delta

Contactor:Siemens

Temperature Controller:Omron

Inverter:Siemens/ABB/Delta

Contactor:Siemens

Machine List

|

1

|

SJSZ65/132 Conical Twin Srew Plastic Extruder

|

1set

|

|

2

|

Mould

|

1set

|

|

3

|

Vacuum Calibration Tank

|

1set

|

|

4

|

Hauling Machine –

|

1set

|

|

5

|

Pipe Cutting Machine

|

1set

|

|

6

|

Stacker

|

1set

|

Production Process

PVC powder + additive — mixing—material feeder—twin screw extruder—mould and calibrator—vacuum forming machine—spraying cooling machine—haul-off machine—cutting machine—discharge rack or pipe belling machine.

Final Product & Application

Our Advantage

A.We are specialized in the extruder making machine production line for 5 years, price is competitive.

B.We owned many experienced staff, who are on this field for no less than 7years, youthful and efficient.

C.We can meet any demands from our clients, different package, different design, different brand name, different color.....Whatever you care, we can serve you the best.

D.We give our clients the word-- the best quality, while we can provide customers the competitive value.

E.We hold powerful production capacity. If you are urgent, please call us and we will take the least time to make it.

F.We are one of the best cooperator for you to choose.

B.We owned many experienced staff, who are on this field for no less than 7years, youthful and efficient.

C.We can meet any demands from our clients, different package, different design, different brand name, different color.....Whatever you care, we can serve you the best.

D.We give our clients the word-- the best quality, while we can provide customers the competitive value.

E.We hold powerful production capacity. If you are urgent, please call us and we will take the least time to make it.

F.We are one of the best cooperator for you to choose.

Company Introduction

Qingdao Wings Plastic Technology Co, Ltd, is the professional manufacturer and exporter of the plastic extrusion line, our company passed the ISO 9001- 2008 international quality system certification and all products have acquired CE certificate of EU. For years, the company has leading technology for plastic extrusion system in the world market, such as high speed corrugated pipe extrusion line, plastic PET PP strap production line, plastic pipe extrusion line, plastic sheet / floor mat extrusion line. Our extrusion line has high technology content and practicability, it is popular in domestic market and exported to more than twenty countries including: USA, India, Brazil, Turkey, Pakistan, Egypt, Ukraine,Namibia,Paraguay etc. Company focus on the plastic extrusion line manufacturing over years, top quality top service. We focus on the quality control, and hope to build a long time business rlationship with customers.

After-sales service

Service Before Sale

1. 24 hours online. Your inquiry will be quick reply by email. Also can go through all questions with you by any online chatting tools (Wechat, Whatsapp, Skype, Viber, QQ, TradeManager )

2. Professionally and patiently introduction,details pictures and working video to show machine

2. Professionally and patiently introduction,details pictures and working video to show machine

Service On Sale

1. Test every machine and inspect the machine seriously.

2.Send the machine picture which you order, then packing it with standard export wooden box after you confirm the machine is ok.

3.Delivery: If ship by sea .after delivery to seaport. Will tell you the shipping time and arrival time. Finally, send all

original documents to you by Express For Free. If delivery it by Express to your door (DHL, TNT, Fedex, etc) or by air to your

airport, Or logistic to the warehouse which you request. We will tell you the tracking number after delivery.

Service After Sale

1. 24 hours online to solve any problem. Supply you English manual book and technical support, maintain and install video to help you solve the problem, or dispatch worker to your factory. All the symbols on the equipment should be in English. Seller is responsible to provide general layout plan, electric plan, installation direction, and manual book in English to Buyer on time.

Wings will provide long-term technical guide.

1. Test every machine and inspect the machine seriously.

2.Send the machine picture which you order, then packing it with standard export wooden box after you confirm the machine is ok.

3.Delivery: If ship by sea .after delivery to seaport. Will tell you the shipping time and arrival time. Finally, send all

original documents to you by Express For Free. If delivery it by Express to your door (DHL, TNT, Fedex, etc) or by air to your

airport, Or logistic to the warehouse which you request. We will tell you the tracking number after delivery.

Service After Sale

1. 24 hours online to solve any problem. Supply you English manual book and technical support, maintain and install video to help you solve the problem, or dispatch worker to your factory. All the symbols on the equipment should be in English. Seller is responsible to provide general layout plan, electric plan, installation direction, and manual book in English to Buyer on time.

Wings will provide long-term technical guide.

FAQ

Q:Are you machinery factory or trading company?

A:We are machinery factory

Q:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

Q: How can we visit your company and machines?

A : Our factory is in Jiaoxi Town, Qingdao City, Shandong Province, China. About 0.5 hours from Qingdao Jiaodong International Ariport.

Q:What`s the payment method?

A: T/T, L/C,Western Union,etc

A:We are machinery factory

Q:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

Q: How can we visit your company and machines?

A : Our factory is in Jiaoxi Town, Qingdao City, Shandong Province, China. About 0.5 hours from Qingdao Jiaodong International Ariport.

Q:What`s the payment method?

A: T/T, L/C,Western Union,etc

Recommend Products

Hot Searches