- Product Details

- {{item.text}}

Quick Details

-

Power:

-

1.9kw

-

Weight:

-

270 KG

-

Dimension(L*W*H):

-

1780X1150X1430mm

-

belt speed:

-

3-15m/min

-

cutting thickness:

-

≥4mm

-

cutting speed:

-

120pcs/min

-

overall dimension:

-

2180x1155x1480

-

Function:

-

beef slicing

-

Processing Types:

-

Automatic fresh Meat Slicer

-

Name:

-

Hiwell beef jerky making machine horizontal meat slicer FQJ380

-

Keywords:

-

Beef Meat Slicer Machine

-

Usage:

-

meat processing factory

-

MOQ:

-

1 Set

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HIWELL

-

Voltage:

-

220v

-

Power:

-

1.9kw

-

Weight:

-

270 KG

-

Dimension(L*W*H):

-

1780X1150X1430mm

-

belt speed:

-

3-15m/min

-

cutting thickness:

-

≥4mm

-

cutting speed:

-

120pcs/min

-

overall dimension:

-

2180x1155x1480

-

Function:

-

beef slicing

-

Processing Types:

-

Automatic fresh Meat Slicer

-

Name:

-

Hiwell beef jerky making machine horizontal meat slicer FQJ380

-

Keywords:

-

Beef Meat Slicer Machine

-

Usage:

-

meat processing factory

-

MOQ:

-

1 Set

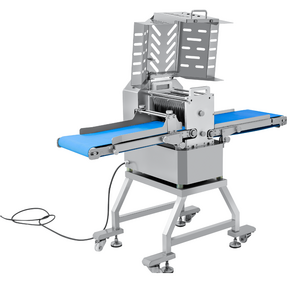

Hiwell beef jerky making machine horizontal meat slicer FQJ380

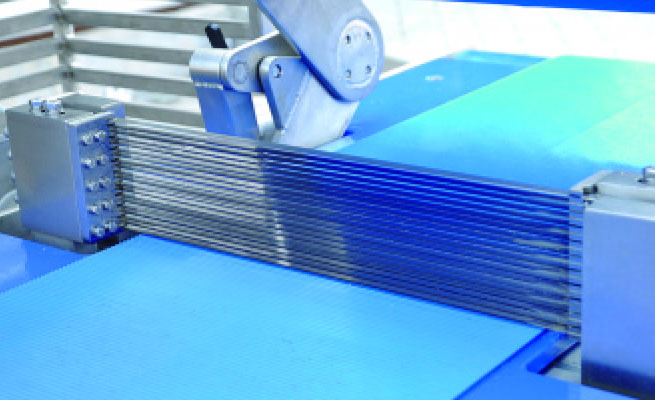

FQJ380 adopts new double floating belt conveying design, widely cutting range (the 380mm width × 120mm height). It can meet customers’ requirements for processing different sizes and various shapes of raw materials which is suitable for fresh boneless meat like beef, lamb, pork, chicken, seafood and cooked products. It can be also used for sliced products such as block shape vegetables. Horizontal conveyor style can realize continuous production with other Hiwell equipment.

Features :

1. Suitable for tough products with tendons or cartilage, or vegetables.

2. Safety switch equipped on the cover. Stainless steel and non-metallic materials.

3. Pneumatical lifting is adopted for compacting the conveyor belt. Easy operation and convenient maintenance.

4. Adjustable cutting thickness; High efficiency and cutting accuracy.

5. The conveyor belt is driven by drum motor. It is safe, reliable and easy to clean

Hiwell beef jerky making machine slicing machine for food factory FQJ380

Benefits:

1. Special multi-blades structure design can realize all the blades to achieve best slicing satiation and minimize the slicing error.

2. Pneumatical double-floating compaction conveying system is adopted, which can be adjusted automatically according to different thickness of raw material

3. The pneumatic system adopts German Festo brand, which is safe and reliable

4. Easy-to-disassemble belts ensure the comprehensive cleaning, CE approved.

Technical parameter :

|

Model |

FQJ380 |

|

Belt width |

380 mm |

|

Belt speed |

3~15m/min |

|

Cutting thickness |

≥4 mm |

|

Cutting speed |

120pcs/min |

|

Max. Product width |

380mm |

|

Input/Output height |

1050±50mm |

|

Power |

2.0 kw |

|

Overall dimension |

2180x1155x1480mm |

Each product will be carefully packed with plastic film package,to make sure it will be

arrived safety.

If choose wooden package,After inspection the goods are packed in plastic film package

and then carefully packed in wooden cartons.

Pre-sale services:

1> Provide the free consultation of the equipment

2> Provide the standard device and the flow chart

3> According to the clients’ special requirement, offering the reasonable plan and free design helping to select the equipment.

4> Welcome to visit our factory or the domestic clients’ factory.

Services during the sales:

1> Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

2> Inspect the machine before leaving the factory.

3> Oversea install and debug the equipment.

4> Train the first-line operator.

After sale services:

1> 24 hours online service

2> Engineers available to service machinery overseas

3> Provide technical exchanging

Q: 1. How long is the warranty period?

A: 1 year

Q: 2. Can you offer the customized machine?

A: Yes. We can offer comprehensive solution to help you after you offer your details requirements.

Q: 3. What is the payment method?

A: TT 30% as downpayment, TT 70% balance before shipment.

Hiwell Machinery CO.,Ltd is a very professional manufacture of forming and coating processing

machinery in the application of fast food processing .For decades we have been focusing on the development of the meat ,seafood and vegetable fast food and developing the former ,batter ,preduster and breader machines and related plants ,successfully found a perfect solution of many kinds of production line for our customer .

Hiwell automatic multi former ,batter ,preduster ,breader ,meat tender ,and batter feeder machines are awarded the authorization of CE ,approved by Germany TUV

Hiwell enormous technological potential keeps the equipment at the highest level in the world .Today we count several reputed firms in Europe ,Southeast Asia,Japan ,Africa ,Australia ect, all over of china as our customer .

Hiwell has a complete quality control system ,advanced design philosophy ,strict management of manufacture process .Thanks to this ,it is possible to keep running the processing plant stably and reality.