- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

110 mm

-

Width of Working Table (mm):

-

5300 mm

-

Dimension:

-

3100x5300x2600mm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

ACCURL

-

Year:

-

new

-

Weight (KG):

-

14300

-

Motor Power (kw):

-

11 kw

-

Warranty of core components:

-

2 years

-

Product name:

-

Panel Center Bender

-

Keyword:

-

Panel Center Bender

-

Type:

-

Hydraulic Bending Tools

-

Application:

-

Stainless Plate Bending

-

Raw Material:

-

Sheet

-

Control system:

-

HC15E-S Touch Screen

-

CNC or not:

-

CNC Bending Machine

-

Color:

-

Customer Choose

-

Material:

-

Metal Steel Sheet

-

Certification:

-

CE ISO SONCAP

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

3200

-

Slider Stroke (mm):

-

110 mm

-

Throat Depth (mm):

-

110 mm

-

Width of Working Table (mm):

-

5300 mm

-

Dimension:

-

3100x5300x2600mm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

ACCURL

-

Year:

-

new

-

Weight (KG):

-

14300

-

Motor Power (kw):

-

11 kw

-

Warranty of core components:

-

2 years

-

Product name:

-

Panel Center Bender

-

Keyword:

-

Panel Center Bender

-

Type:

-

Hydraulic Bending Tools

-

Application:

-

Stainless Plate Bending

-

Raw Material:

-

Sheet

-

Control system:

-

HC15E-S Touch Screen

-

CNC or not:

-

CNC Bending Machine

-

Color:

-

Customer Choose

-

Material:

-

Metal Steel Sheet

-

Certification:

-

CE ISO SONCAP

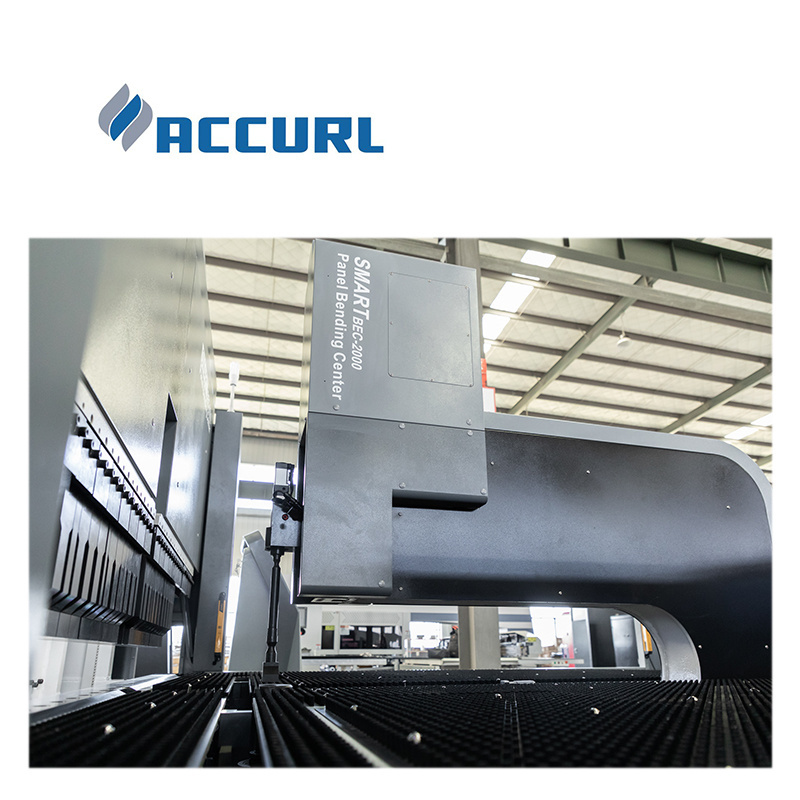

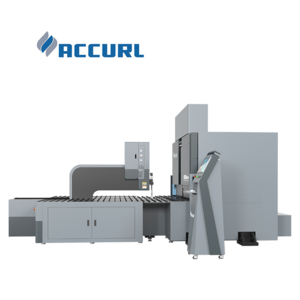

ACCURL BEC series PANEL BENDER CENTER

BEC Series panel bender is the new generation automated bending solutions, a benchmark that indicates the upgrading to automation of sheet metal fabricating industry. It can obviously reduce the labor cost and at the same time it can realize 300% higher efficiency comparing to traditional press brake up to 0.3s per bending. Full electro servo transmission plus closed-loop BUS control makes the accuracy far better.

“MACHINE EXPERT FOR SHEET METAL”

ACCURL is enabling the upgrading of conventional sheet metal fabricating industry and reimaging what can be made.

Details Images

FEATURE-MULTI POSITIONING WAYS

The frame is welded by carbon dioxide shielded welding, which has many advantages such as stable welding process, no internal

defects, and minimal spatter.

defects, and minimal spatter.

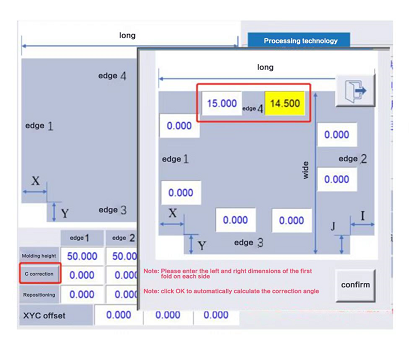

FEATURE-AUTOMATIC CORRECTION OF ROTATION ANGLE

The arc bending process requires repeated bending of the plate. If the rotation angle is not in place, the bending error will

accumulate each time, resulting in the folded workpiece is not an arc, but a cone.

The automatic correction function can automatically adjust the C/C11 axis to compensate for sheet rotation errors.

accumulate each time, resulting in the folded workpiece is not an arc, but a cone.

The automatic correction function can automatically adjust the C/C11 axis to compensate for sheet rotation errors.

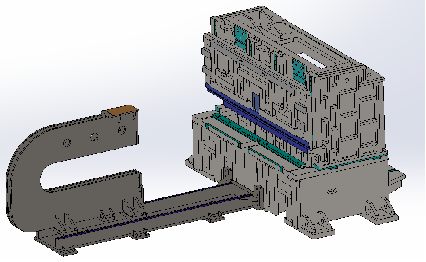

CNC AXES-11 AXES

A/B axes: Positioning axes V axis: Feeding axis C/C11 axes: Rotation axes W/W11 axes: Pressing axes Z/Z11 axes: Tooling up&down

motion axes Y/Y11axes : Tooling forward&dbackward motion axes

motion axes Y/Y11axes : Tooling forward&dbackward motion axes

CONTROLLING SYSTEM

In view of the high-intensity motion requirements of the panel bender, the frame adopts an arch design, which is thickened and widened. The frame is tempered, annealed and aged twice to ensure the long-term running accuracy, stability and high rigidity of the machine.

|

Name

|

Unit

|

BEC-1400

|

BEC-2000

|

BEC-2500

|

|

|

Max. Bending Length

|

mm

|

1400

|

2000

|

2500

|

|

|

Max. Sheet Width

|

mm

|

1400

|

1500

|

1500

|

|

|

Max. Bending Height

|

mm

|

170

|

170

|

170

|

|

|

Min. Workpiece Size (four sides bending)

|

mm

|

110x200

|

110x200

|

110x200

|

|

|

Min. Workpiece Size (single side bending)

|

mm

|

110

|

110

|

110

|

|

|

Min. Radius

|

mm

|

1.2

|

1.2

|

1.2

|

|

|

Bending Angle

|

|

±180

|

±180

|

±180

|

|

|

Max. Bending Speed

|

s/bending

|

0.5

|

0.5

|

0.5

|

|

|

Min. Sheet Thickness

|

mm

|

0.35

|

0.35

|

0.35

|

|

|

Dimensions(L×W×H)

|

mm

|

3000x2000x2600

|

3100x5300x2600

|

3100x5300x2600

|

|

|

Full Power

|

mm

|

36

|

45

|

45

|

|

|

Working Voltage

|

mm

|

380V±10%

|

380V±10%

|

380V±10%

|

|

AST TOOLS FOR SPECIAL APPLICATIONS

The AST tools are modular in length, engaging and disengaging quickly and automatically between the blank and the bending blades.They are used to make bends that are shorter than the side being bent.

Universal Tooling

The Flexible Panel Bender bends the sheet metal with one universal tooling, able to bend various complex shapes. It can fold 90 angle, non 90 angle, circular ARC, positive/negative and other complex shapes, now days flexible panel bender become more and more popular in the metal forming field of different industries and different workpieces.

Here listed some typical applications:

Hot Searches