- Product Details

- {{item.text}}

Quick Details

-

Power:

-

1.3KW

-

Dimension(L*W*H):

-

2100*1600*730mm

-

Weight:

-

500

-

Product name:

-

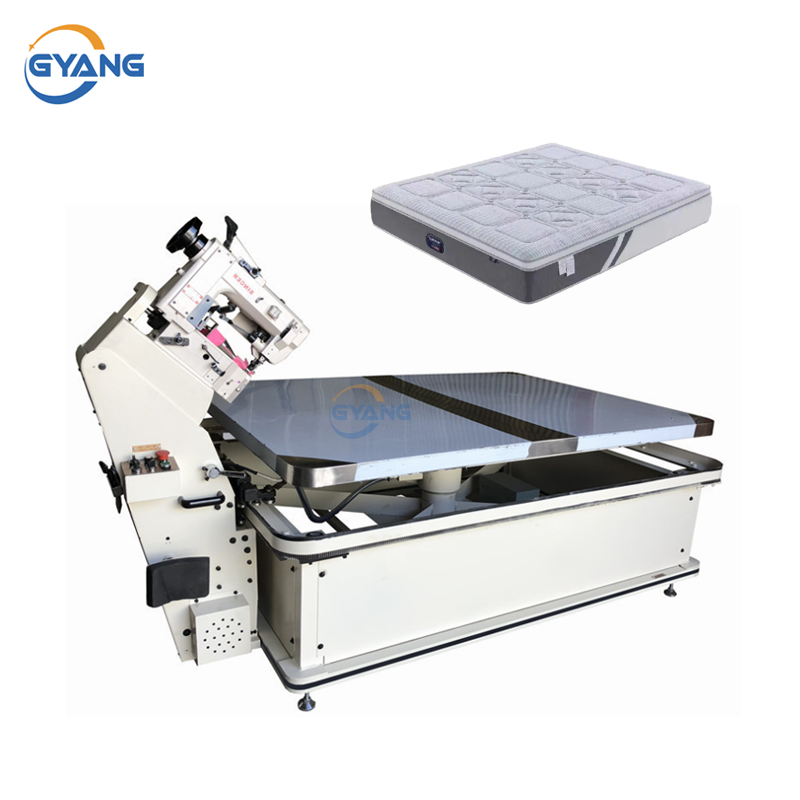

Bed Mattress Making Manufacturing Machinery Mattress Closing Machine

-

Keyword:

-

mattress manufacturing machinery

-

Application:

-

Mattress Tape Edge Binding

-

Function:

-

Automatic Mattress Production

-

Style:

-

Lock Stitch

-

Mattress Thickness:

-

30-400mm

-

Mattress machine:

-

Mattress Edging Binding Machine

-

Usage:

-

Mattress Machinery Automatic

-

Table size:

-

1.5*2M / 1.6*2M /1.8*2M

-

After-sales Service Provided:

-

Service Machinery Overseas

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Henan Gyang Machinery

-

Voltage:

-

220V/380V

-

Power:

-

1.3KW

-

Dimension(L*W*H):

-

2100*1600*730mm

-

Weight:

-

500

-

Product name:

-

Bed Mattress Making Manufacturing Machinery Mattress Closing Machine

-

Keyword:

-

mattress manufacturing machinery

-

Application:

-

Mattress Tape Edge Binding

-

Function:

-

Automatic Mattress Production

-

Style:

-

Lock Stitch

-

Mattress Thickness:

-

30-400mm

-

Mattress machine:

-

Mattress Edging Binding Machine

-

Usage:

-

Mattress Machinery Automatic

-

Table size:

-

1.5*2M / 1.6*2M /1.8*2M

-

After-sales Service Provided:

-

Service Machinery Overseas

Products Description

Bed Mattress Making Manufacturing Machinery Mattress Closing Machine

This machine is mainly used for sewing between the top and bottom fabric and the side edge material of Simmons mattress.

Bed Mattress Making Manufacturing Machinery Mattress Closing Machine

The machine has the characteristics of adjustment of head elevation Angle, head lifting adjustment, sewing speed adjustment, etc. When sewing, the mattress is transported by the workbench conveyor belt for sewing.

PLC program control and artificial intelligence operation are adopted.

The mattress can automatically walk, automatically turn and automatically turn during sewing, which improves the sewing speed.

Bed Mattress Making Manufacturing Machinery Mattress Closing Machine

The machine head in the corner of the sewing mattress can automatically lift, automatically slow down, automatic recovery, improve the sewing quality, to solve the problem of four corners of the edge warp.

Mattress sewing only needs one person to operate, improve work efficiency and reduce labor intensity, is the ideal equipment for mattress manufacturing and assembly line production.

Details Images

1. Electric lifting of the table, electric adjustment of the Angle of the head;

2. The sewing slide frame is driven by electric speed regulation, and the turning position adopts automatic deceleration;

3. Induction brake, more labor-saving and durable;

4. Straight, uniform and beautiful stitching, stable operation, small vibration, small noise.

Product Parameters

|

Model

|

GY-WB1480

|

GY-WB1500

|

GY-WB1560

|

|

Corner automatic deceleration

|

Yes

|

Yes

|

Yes

|

|

Machine head working angle

|

35°-55°

|

35°-55°

|

35°-55°

|

|

Work table lifting mode

|

Table manual lifting, four corners manual lifting

|

Electric (four Angle lift)

|

Electric (intermediate lift)

|

|

Mattress thickness sewing range

|

50-400mm

|

50-400mm

|

20-420mm

|

|

Workbench lifting range

|

260mm

|

260mm

|

260mm

|

|

Table size

|

1480 * 1920mm

|

1500*2000mm

|

1560*1960

|

|

Walking speed (m/min)

|

6~16

|

6~16

|

6~16

|

|

Production efficiency

|

15(bed/hour)

|

18(bed/hour)

|

20(bed/hour)

|

|

Voltage

|

Single-phase 220V

|

Single-phase 220V

|

220V/380V

|

|

Total motor power

|

400W

|

800W

|

1200W

|

|

Total weight

|

330KG

|

400KG

|

550KG

|

|

Outer packing

|

1920*1580*800mm

|

2250*1650*800mm

|

2250*1750*800mm

|

Product Packaging And Shipping

1. We will send you the photos and videos of the machine before delivery. After the machine is confirmed that there is no problem, it will be packed and shipped.

2. Our machines are packed in standard export wooden cases and cartons. If it is a large machine and a production line machine, we recommend that you use a small container.

3. When the machine sails, we will send you the customs clearance information and documents to help you smooth customs clearance. We will also send you the tracking information of the shipment so that you can keep track of the shipment status at all times.

Our Factory

Why Choose Us

Our products has passed ISO 9001 International Quality Management System Certification and is exported to America, Canada, Chile, Indonesia, Cambodia, Malaysia, Kenya.Britain, Thailand, Egypt, South Korea, Spain, Ukraine, Argentina,Netherlands, Japan, Germany, Australia, France, Italy, Mexico, South Africa, Turkey, Romania, Sweden, Finland, etc. about more than 60 countries and area. We have won good reputation depends on our best qualified products and after-sales.

Bed Mattress Making Manufacturing Machinery Mattress Closing Machine

FAQ

Contact Us

Hot Searches