- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

Mixture

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Madoff

-

Model Number:

-

M-205

-

Type:

-

Liquid, polyurethane

-

Product name:

-

Liqud Polyurethane with waterproof coating

-

Surface dry:

-

≤8

-

Full dry:

-

≤24

-

Abrasion resistance(750g/500r)g:

-

≤0.020

-

Slip resistance:

-

≥0.60

-

Compressive strength / MPa:

-

≥50

-

Water absorption rate %:

-

≤0.10%

-

Key word:

-

waterproof coating

Quick Details

-

CAS No.:

-

Mixture

-

Other Names:

-

polyurethane waterproofing coating

-

MF:

-

Mixture

-

EINECS No.:

-

Mixture

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Madoff

-

Model Number:

-

M-205

-

Type:

-

Liquid, polyurethane

-

Product name:

-

Liqud Polyurethane with waterproof coating

-

Surface dry:

-

≤8

-

Full dry:

-

≤24

-

Abrasion resistance(750g/500r)g:

-

≤0.020

-

Slip resistance:

-

≥0.60

-

Compressive strength / MPa:

-

≥50

-

Water absorption rate %:

-

≤0.10%

-

Key word:

-

waterproof coating

polyurethane coating glue acryl emulsion adhesive concrete adhesive glue for playground flooring rubber

Product Description

M-205 Liquid Polyurethane Epoxy Resin

is made of high-performance waterborne polyurethane resin as the base material, high strength cement, active grade silica sand and pigment as the aggregate, which is four components of colorful water-borne mortar floor coating rich in resin.Waterborne polyurethane mortar non-slip floor has good wear resistance, impact resistance, chemical resistance and other physical erosion, can bear heavy load.

Specification

|

Inspection items

|

|

|

|

Parameter values

|

|

|

|

||||||

|

State in container

|

|

|

|

After stirring, there is no hard block and it is uniform

|

|

|

|

||||||

|

Coating appearance

|

|

|

|

Flat, no play mark, wrinkle, pinhole, bubble and other defects

|

|

|

|

||||||

|

Drying time H (25℃)

|

|

|

|

Surface dry ≤8

|

|

|

|

||||||

|

|

|

|

|

Full dry ≤24

|

|

|

|

||||||

|

Hardness/H

|

|

|

|

≥H

|

|

|

|

||||||

|

Impact resistance

Steel ball(50mm*500g 100cm high) |

|

|

|

Coating without crack, no peeling

|

|

|

|

||||||

|

Abrasion resistance(750g/500r)g

|

|

|

|

≤0.020

|

|

|

|

||||||

|

Slip resistance

(dry friction coefficient) |

|

|

|

≥0.60

|

|

|

|

||||||

|

Tensile bond strength, 7d standard condition/MPa

|

|

|

|

≥2.0

|

|

|

|

||||||

|

Low/high temperature resistance test

|

|

|

|

Can withstand -40℃ to 120℃ cycle change

|

|

|

|

||||||

|

Compressive strength / MPa

|

|

|

|

≥50

|

|

|

|

||||||

|

Water absorption rate %

|

|

|

|

≤0.10%

|

|

|

|

||||||

|

Water resistance (168H)

|

|

|

|

No foaming, no peeling, allow slight discoloration

|

|

|

|

||||||

|

Chemical resistance

|

|

15% NaOH solution 72h

|

|

|

No foaming, no peeling, allow slight discoloration

|

|

|

||||||

|

|

|

10% HC1 solution 72h

|

|

|

No foaming, no peeling, allow slight discoloration

|

|

|

||||||

|

|

|

120# solvent gasoline 72h

|

|

|

No foaming, no peeling, allow slight discoloration

|

|

|

||||||

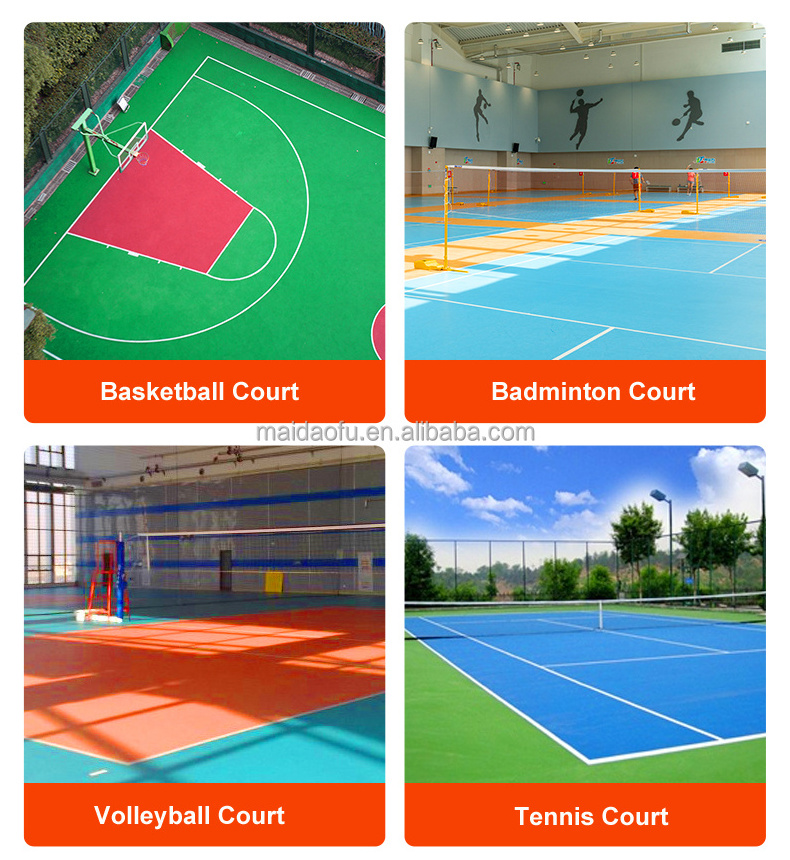

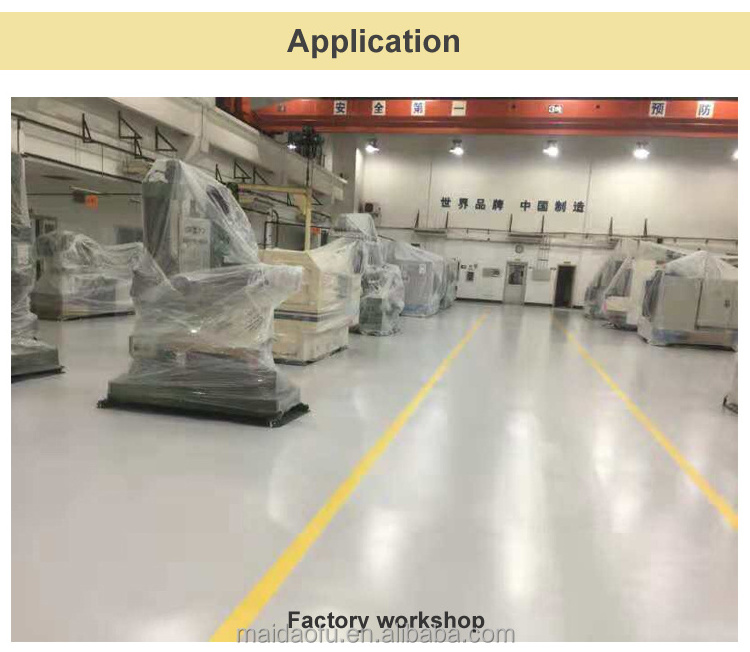

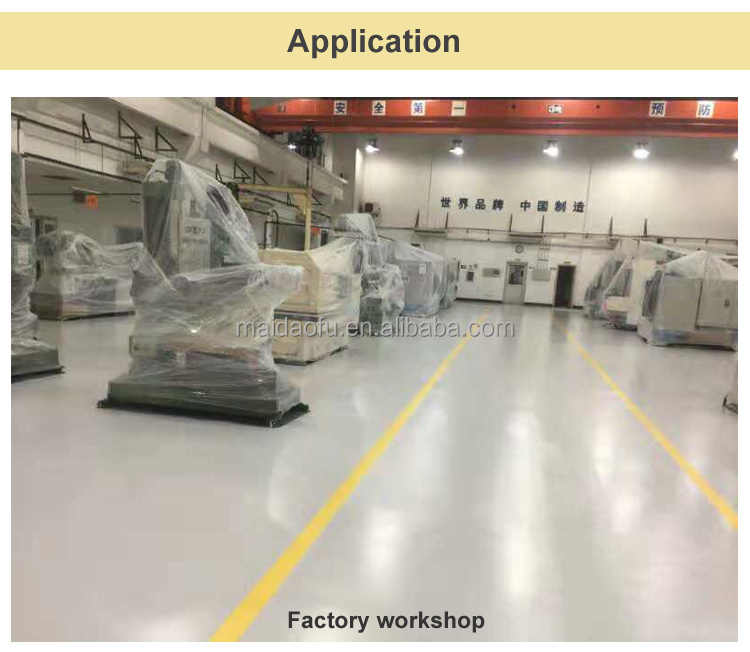

Applications

M-205 can be used in the following workshop, factory floor: food processing plant, dairy plant, distillery, distillery;

Production workshops and laboratories of pharmaceutical intermediates;Wet and dry processing area, cold storage, freezing area;Chemical processing plant, pulp and paper industry factory, large warehouse and storage area floor area.

Production workshops and laboratories of pharmaceutical intermediates;Wet and dry processing area, cold storage, freezing area;Chemical processing plant, pulp and paper industry factory, large warehouse and storage area floor area.

Construction parameters

|

Process name

|

|

Specific practice and requirements

|

|

|

|

|

|

||||||

|

Base surface treatment

|

|

1.On the base surface for heavy sandblasting or milling processing, if there is any drainage hole, should be near and around the

vertical pendant for hook type cutting. 2.Draw a diagonal line on the base and cut along the line to a depth of about 20mm to prevent shrinkage of the coating. 3.Clean up the ground sand and remove the residual dust with a vacuum cleaner. |

|

|

|

|

|

||||||

|

Sealing coating

|

|

1. Use the interface agent to spread evenly on the clean base surface.

2. Then spread the quartz sand over the still wet primer.The materials must be used up within 25 minutes after mixing. 3. After the primer is solidified, remove the excess quartz sand, polish the base surface and remove the residual dust with industrial vacuum cleaner. |

|

|

|

|

|

||||||

|

Paint coating

|

|

1. After the closed layer is dry, use the four component materials to mix carefully and stir for about 3 minutes to reach a smooth and uniform mortar state. 2. Smooth the material with a flat knife and evenly scrape it on the surface of the dry and solid closed layer to the required thickness. It is not advisable to wipe it repeatedly to ensure the uniform distribution of liquid materials. 3. Roll the surface evenly with a water-wetted wool roller.The materials must be used up within 25 minutes after mixing. |

|

|

|

|

|

||||||

Our Advantages

We are a professional manufacturer engaged in the research,development,productions and sales of acrylic type pressure sensitive adhesive,solvent based acrylic resin ,epoxy Resin and polyisocyanate hardener 10 years.

We make sure to offer the best service for our customers!

We make sure to offer the best service for our customers!

Hot Searches