- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

170 mm

-

Width of Working Table (mm):

-

1400 mm

-

Dimension:

-

5100*2300*3600mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HSSK

-

Year:

-

new

-

Weight (KG):

-

8000

-

Motor Power (kw):

-

45 kw

-

Product name:

-

Hydraulic Cnc Bending Machine

-

After-sales Service Provided:

-

Online Support

-

Application:

-

Stainless Plate Bending

-

Bending height:

-

180mm

-

Number of axes:

-

11/12 optional

-

Type:

-

Hydraulic Bending Tools

-

The fastest continuoue bending speed:

-

0.5s

-

Bending angle:

-

0-180°

-

Minimum arc radius:

-

1.2mm

-

Minimum forming size of two.sides:

-

200mm

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

1400

-

Slider Stroke (mm):

-

1500 mm

-

Throat Depth (mm):

-

170 mm

-

Width of Working Table (mm):

-

1400 mm

-

Dimension:

-

5100*2300*3600mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HSSK

-

Year:

-

new

-

Weight (KG):

-

8000

-

Motor Power (kw):

-

45 kw

-

Product name:

-

Hydraulic Cnc Bending Machine

-

After-sales Service Provided:

-

Online Support

-

Application:

-

Stainless Plate Bending

-

Bending height:

-

180mm

-

Number of axes:

-

11/12 optional

-

Type:

-

Hydraulic Bending Tools

-

The fastest continuoue bending speed:

-

0.5s

-

Bending angle:

-

0-180°

-

Minimum arc radius:

-

1.2mm

-

Minimum forming size of two.sides:

-

200mm

Products Description

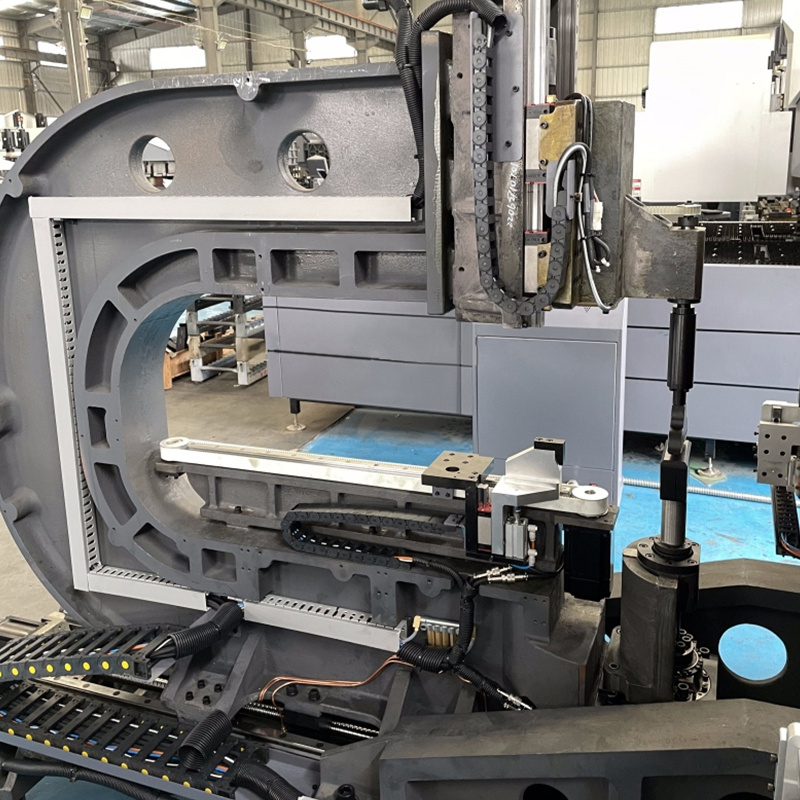

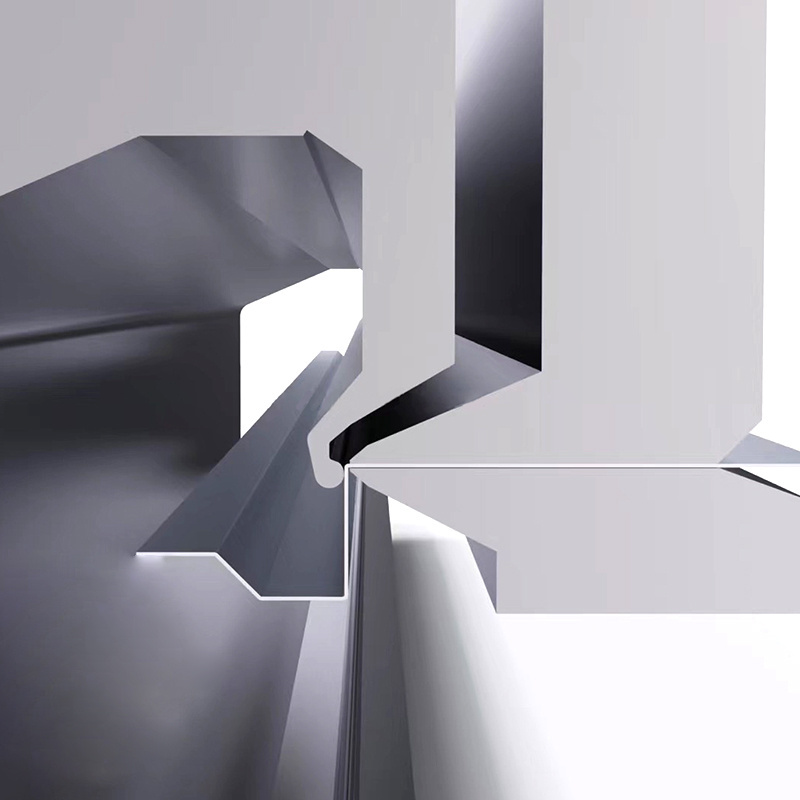

Details Images

Technical parameter

|

2500P Series Configuration Parameters

|

|

|

|

Fastest bending speed

|

0.2s/time

|

|

|

Maximum bending width

|

2500mm

|

|

|

Bending height

|

170 mm

|

|

|

Rated voltage

|

380V

|

|

|

Peak power

|

28KW

|

|

|

Average power

|

2.8KW

|

|

|

Noise

|

50 dB

|

|

|

Total mass

|

19 tons

|

|

|

Maximum bending thickness

(Standard )

|

UTS 515N/mm2 201stainless steel 0.8mm

UTS 520N/mm2 304stainless steel 1.0mm

UTS 410N/mm2 cold plate 1.2mm

UTS 265N/mm2 aluminum plate 1.6mm

|

|

|

Minimum material thickness

|

0.35mm

|

|

|

Minimum inner size of four-side forming

|

140mm*190mm

|

|

|

Minimum inner size of bilateral forming

|

140mm

|

|

|

Maximum bending size

|

2500mm*1250mm

|

|

|

Number of axes

|

Standard 13-axis concurrent linkage

|

|

The flexible bending center focuses on solving various complicated sheet metal and bending problems in metal forming. Through multi-axis concurrent linkage, sheet metal operations are automatically completed, and the dependence on molds and labor is resolved from a technical perspective, which effectively improves production efficiency and reduces production costs. Easily realize the arc, press dead edge, back shape, closed shape and other complex sheet metal bending requirements. The flexible bending center can be widely used in the field of steel cabinet shells (file cabinets, tool cabinets, outer shields, electrical cabinets, communication cabinets, gas cabinets, water meter cabinets...), kitchen utensils (refrigerators, air conditioners, stoves...) , Furniture, ventilation, refrigeration, purification, door industry, decoration, elevator and other related metal forming fields

Related Products

Hot Searches