- Product Details

- {{item.text}}

Quick Details

-

Power:

-

11KW

-

Dimension(L*W*H):

-

360cm*230cm*160cm

-

Weight:

-

1200 KG

-

Effective working size:

-

Other sizes can be customized

-

Cutting speed:

-

100-3000mm/s

-

Pan speed:

-

100-3000mm/s

-

cutting tool:

-

Mop knife, half-cut knife, round punch

-

Cutting thickness:

-

0.1-25mm

-

Fixed material method:

-

Vacuum pump adsorption

-

Transport interface:

-

Network port, USB port, can be operated offline

-

Supports software formats:

-

PLT, DXF and other formats

-

Cutting accuracy:

-

±0.1mm

-

Safeguards:

-

Infrared induction anti-collision device, emergency stop button device

Quick Details

-

Voltage:

-

220-380V

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Bangzheng Machinery

-

Power:

-

11KW

-

Dimension(L*W*H):

-

360cm*230cm*160cm

-

Weight:

-

1200 KG

-

Effective working size:

-

Other sizes can be customized

-

Cutting speed:

-

100-3000mm/s

-

Pan speed:

-

100-3000mm/s

-

cutting tool:

-

Mop knife, half-cut knife, round punch

-

Cutting thickness:

-

0.1-25mm

-

Fixed material method:

-

Vacuum pump adsorption

-

Transport interface:

-

Network port, USB port, can be operated offline

-

Supports software formats:

-

PLT, DXF and other formats

-

Cutting accuracy:

-

±0.1mm

-

Safeguards:

-

Infrared induction anti-collision device, emergency stop button device

Product Description

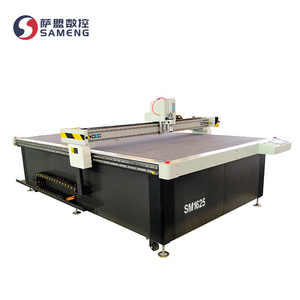

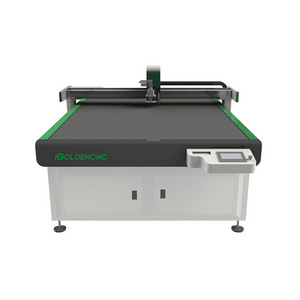

Bangzheng CNC Leather Cutting Machine Product Description

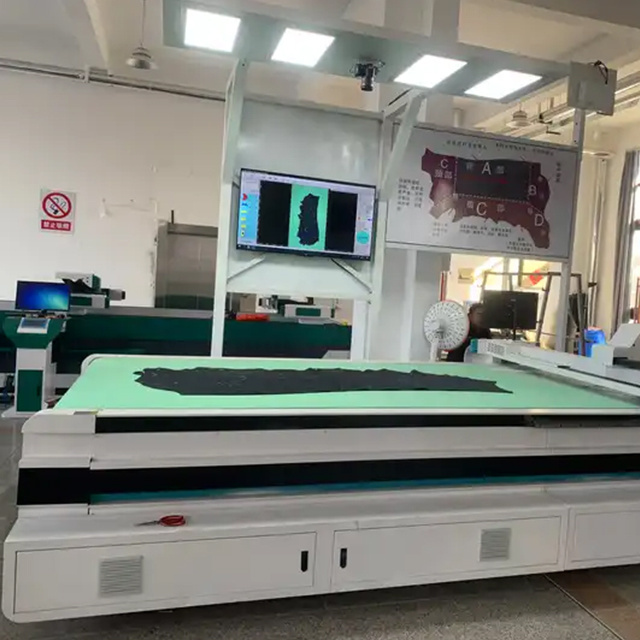

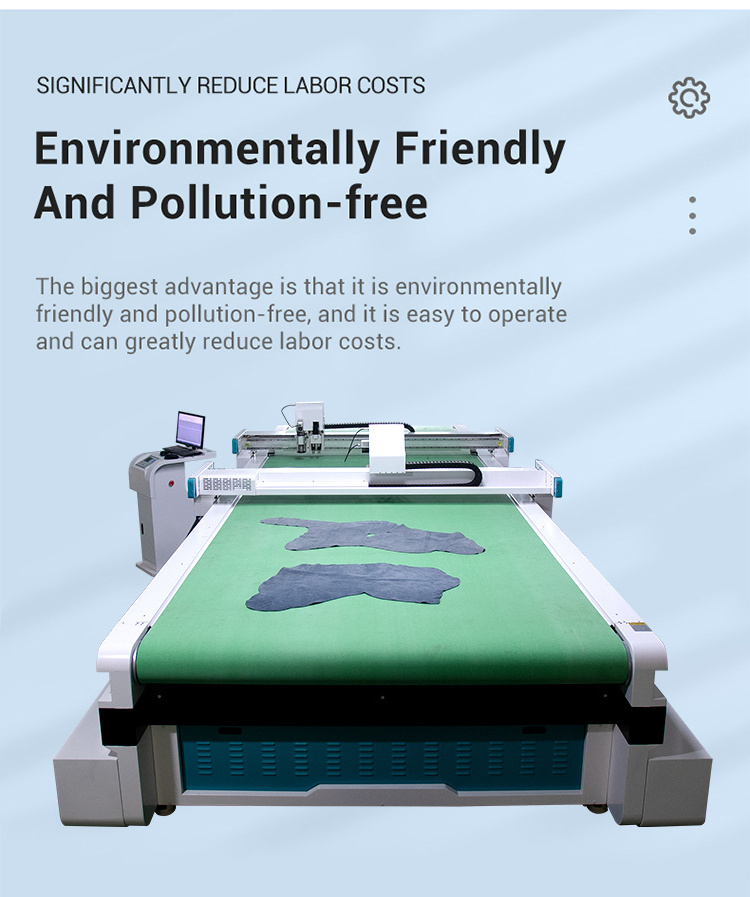

Bangzheng CNC leather cutting machine provides an overall solution for PU artificial leather and natural leather cutting.

For natural leather, it can intelligently identify contours and defects on the material, and then automatically lay out materials, saving time and improving utilization.

For artificial leather, it can be automatically fed and cut without stopping, ensuring cutting accuracy and efficiency.

Bangzheng Leather Cutting Machine will help you move from the traditional manual production and cutting mode to high-speed, precise and intelligent modernity, and provide diversified and personalized cutting services.

Product parameters

|

Model

|

|

1860(Size can be customized)

|

|

|

|

||||

|

Working Area

|

|

1800*6000mm(Size can be customized)

|

|

|

|

||||

|

Cutting Thickness

|

|

0.1-25.0mm according to materials |

|

|

|

||||

|

Function

|

|

Capturing, cutting, notching, marking, etc. |

|

|

|

||||

|

Applied Materials

|

|

All kinds of real leather, PU leather, fabric, paper, pvc, etc. |

|

|

|

||||

|

Supported File Format

|

|

DXF, PLT

|

|

|

|

||||

|

Power Supply

|

|

Customized according to local power supply |

|

|

|

||||

|

Rated Power

|

|

11KW |

|

|

|

||||

product details

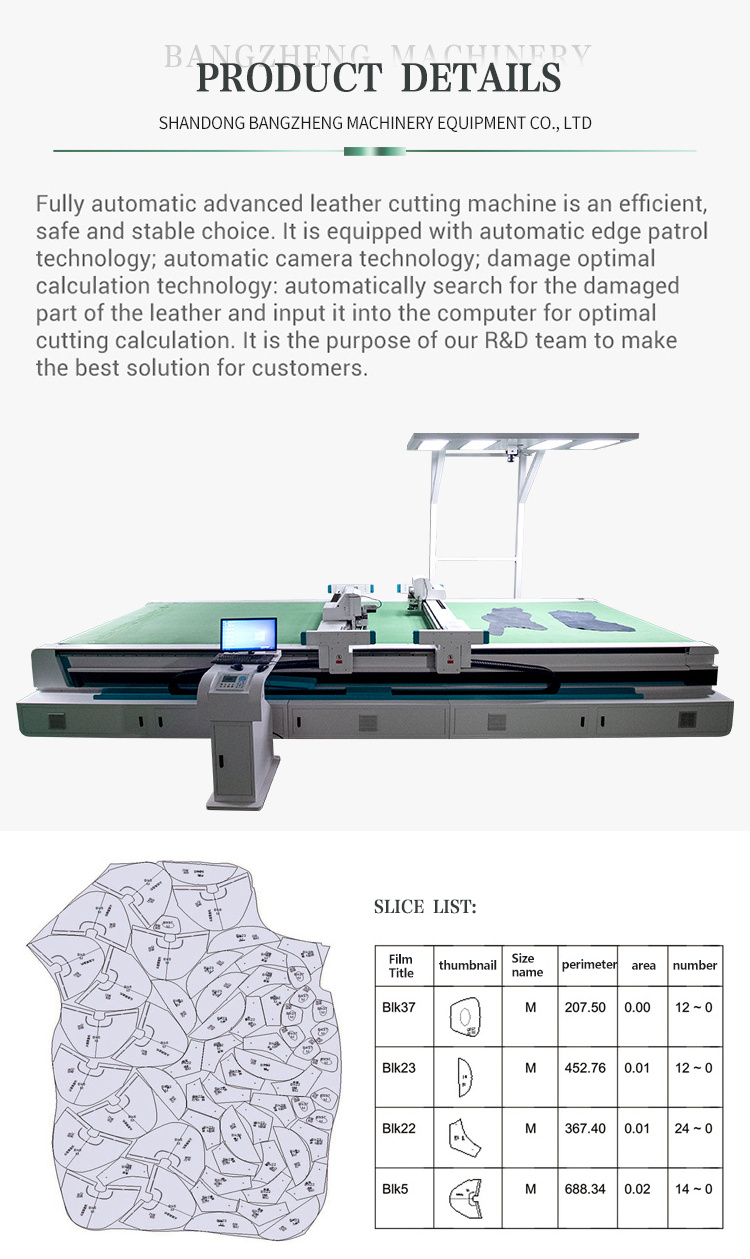

Knife type selection

Advantages of intelligent typesetting system

: One machine is multi-purpose and saves cost One typesetting room can be equipped with2-3 leather blanking machines.High utilization of automatic scanning and typesetting; Fast typesetting speed; SavematerialwasteTypesetting in advance saves overall time; Reduce the typesetting process of leatherllin-one machine and improve work efficiency.

Cutting renderings

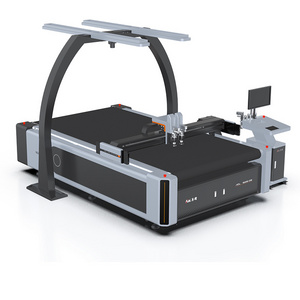

Low leather smart cutting bed will be cut in the form of a vacuum adsorption material adsorption on the workbench, by hd projectors system will cut Graphical projection in 1:1 form on the material, to achieve high precision positioning cutting, intuitive layout pattern projection system as a whole, can improve the utilization rate of raw materials to the greatest extent, reduce the production cost.

Theintelligent leather cutting bed is equipped with multifunction cutting head, collection knife, pen, mold and one, which can achieve holing, marking, cutting, marking point complete at one time, integration of production processes, improve production efficiency.

The real leather intelligent cutting bed can realize the network interconnection, the board room, the workshop may carry on the seamless connection through the wired, the wireless way, enhances the management efficiency.

Cut finished product

Process flow

Enterprise honor

Hot Searches