- Product Details

- {{item.text}}

Quick Details

-

Power:

-

150kw

-

Dimension(L*W*H):

-

40X10X15m

-

Warranty:

-

1 Year

-

Weight:

-

120t

-

Certification:

-

ISO9001:2008, ISO, IEC

-

Item:

-

Continuous Casting Machine

-

Control system:

-

PLC simens control

-

Continuous casting machine:

-

with R 6m or more or less

-

CCM radius:

-

from R2m to R12m

-

Rounds diameter:

-

80-320sq.mm

-

Strand No:

-

from 1 to 8

-

Billet length:

-

3-12m

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

SMKJ

-

Voltage:

-

380V

-

Power:

-

150kw

-

Dimension(L*W*H):

-

40X10X15m

-

Warranty:

-

1 Year

-

Weight:

-

120t

-

Certification:

-

ISO9001:2008, ISO, IEC

-

Item:

-

Continuous Casting Machine

-

Control system:

-

PLC simens control

-

Continuous casting machine:

-

with R 6m or more or less

-

CCM radius:

-

from R2m to R12m

-

Rounds diameter:

-

80-320sq.mm

-

Strand No:

-

from 1 to 8

-

Billet length:

-

3-12m

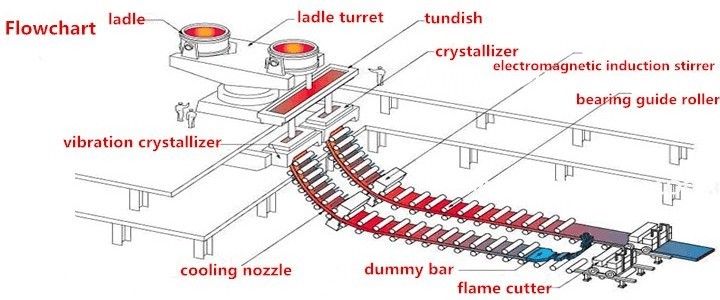

Continuous Casting Machine

CCM radius: from R2m to R12m

Rounds diameter: 80-320sq.mm

Strand No.: from 1 to 8

Billet length: 3-12m

1. Equipment foundation and civil works

11. Dummy bar

2. Steel structure platform

12. Dummy bar storage device

3. Casting radius

13. Withdrawal straightening machine

4. Strand number

14. Approach roller table

5. Ladle support

15. Automatic cutting machine

6. Tundish

16. Transmit roller table

7. Tundish car

17. Cooling bed

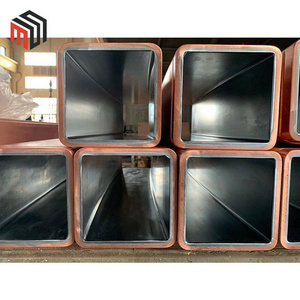

8. Mould

18. Pusher

9. Oscillation device

19. Hydraulic system

10. Secondary cooling system

20. Computer and PLC system

21. Tundish roaster

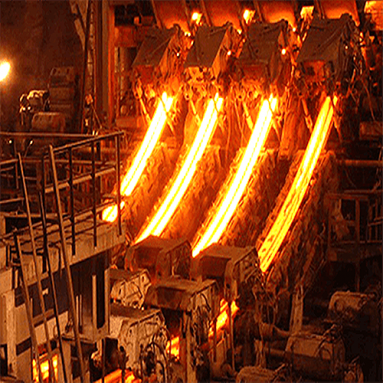

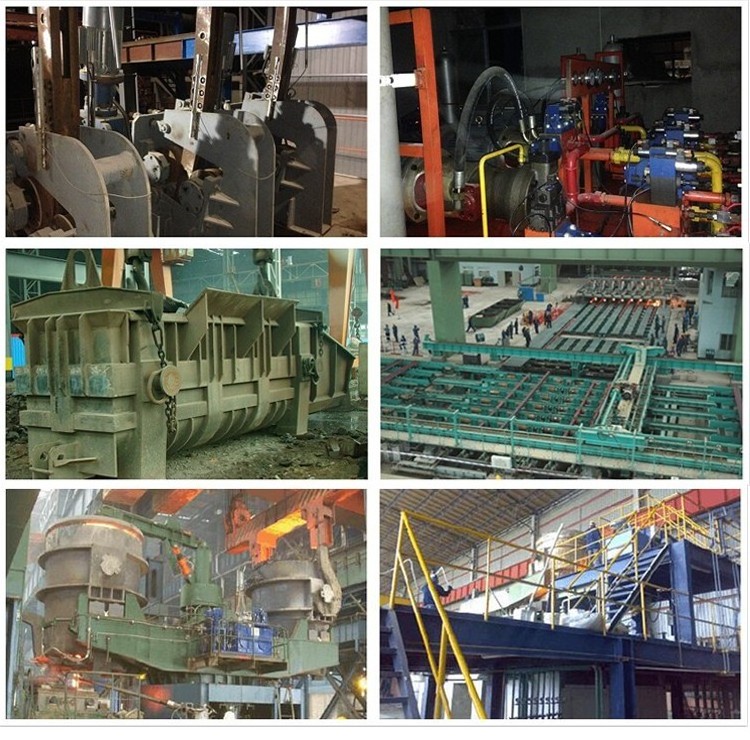

The billet continuous casting machine can be designed as curved and vertical-bend according to the users requirements. It can cast carbon steel, alloy steel and special steel, such as stainless steel. Automatic hydraulic control, automatic secondary cooling water distribution, compressed air-water cooling system. Technical support, design, feasibility report, manufacturing, erection and commissioning, cooperate with special institution, and our own engineer team, we do not only export the machinery, but also run the factory.

1. Strip plate mould of the entirety copper-tube mode which is simple and low cost.

2. High-frequency and small-swing plate spring vibration, the depth of vibration mark is under 0.2mm.

3. The simplified billet guiding device is low cost and easy maintenance.

4. Five-roller and four-drive straightening machine is of the large straightening.

5. Auxiliary straightening machine can re-straighten the billet in emergency.

6. Stainless steel cutting machine can cut-to-length accurately.

7. The coping rate in the surface is less than 5%.

8. Computer and PLC system

9. Tundish roaster

Please link our website:

www.cdoinduction.com

Get more useful information

Skype : mandymeina

Cell phone : 0086-15168765707