Hengshui huake rubber & plastic co.,LTD.Is a comprehensive enterprise that introducesforeign advanced technology, integrates development,design, manufacturing and processing.

The company is committed to the r&d and production of high performance products of newrubber and plastic materials supporting equipment in the new energy photovoltaic andenvironmental protection water treatment industry. The company has passed iso9001-2008product quality certification and registered brand "NER" in the spirit of improving productquality and building a first-class brand,providing high-quality products and the mosthumanized services for customers.

Focus on the research and development of application technology in synthetic rubber industry. The factory has established a set of rubber vulcanization curve control system and introduced the production and testing equipment of rubber products. Under the complex and rigorous control mechanism and the application of advanced production, management and testing technology, it has achieved the consistency of all product processes, that is, product design, formula development, raw material mixing, mold processing, inspection, performance test, manufacturing, etc. The organic combination of rubber product manufacturing and rubber raw material formula development has laid a solid foundation for the company in innovative design and market development. It has obtained a number of patent certificates in terms of new structure sealing ring and product production process. The company takes innovative technology and meeting user needs as its business philosophy, makes every effort to build ner brand, and provides reasonable and advanced solutions for many supporting manufacturers of industrial enterprises. This relationship ensures the high-quality products of the original design manufacturer (ODM) and contributes to the company's technical background for future development planning. This cooperation enables the original manufacturer (ODM) and the company to obtain continuous competitive advantages. Today, NER has become a rubber component supplier with certain competitive advantages in the global rubber market. Its products are mainly used in fluid sealing equipment in sewage treatment, automobile, aviation, machinery, petrochemical, medical treatment, food, electronics, national defense, military and other industries.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HUAKE-698

-

Product Name:

-

butyl thread adhesive board

-

Working temperature:

-

-70℃ to 260 ℃

-

Thickness:

-

1mm 2mm 3mm 4mm

-

Width:

-

1m

-

Color:

-

black

-

Type:

-

hot press pad

-

Feature:

-

heat resistant

-

Material:

-

butyl

-

Surface:

-

Smooth

-

Package:

-

one roll in a woven bag

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HUAKE

-

Model Number:

-

HUAKE-698

-

Product Name:

-

butyl thread adhesive board

-

Working temperature:

-

-70℃ to 260 ℃

-

Thickness:

-

1mm 2mm 3mm 4mm

-

Width:

-

1m

-

Color:

-

black

-

Type:

-

hot press pad

-

Feature:

-

heat resistant

-

Material:

-

butyl

-

Surface:

-

Smooth

-

Package:

-

one roll in a woven bag

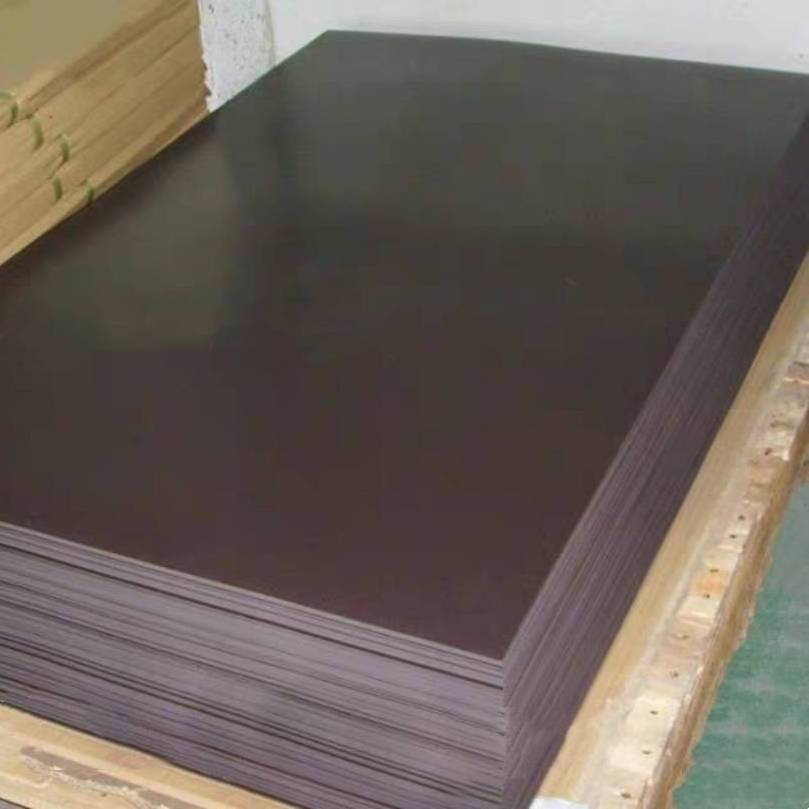

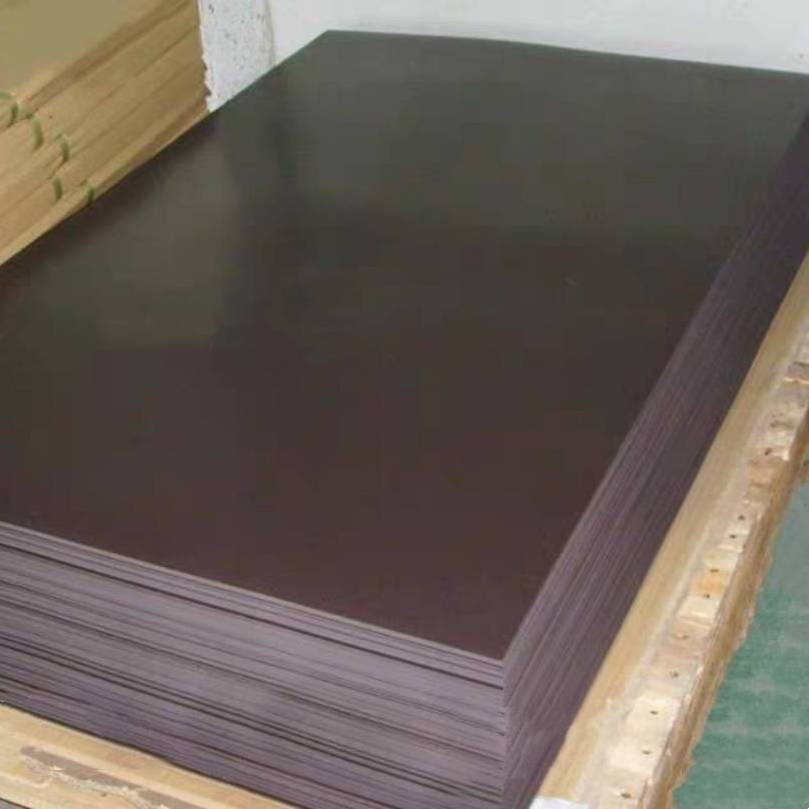

Details Images

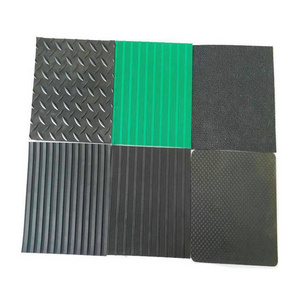

Uses of rubber sheets

Rubber sheets are mainly used in military, aviation, industrial construction and other industries. According to its performance, it can be used in shock absorption, sealing, gasket and oil resistance, acid and alkali resistance and insulation.

Industry: Rubber sheets are mainly used in anti-corrosion, wear-resisting and impact-resistance to protect the equipment and devices used.

Mining: In this field, rubber sheets mainly play the role of impact resistance and wear resistance to protect their equipment and related pipeline equipment, so that the service life of their equipment can be extended.

We can produce silicone sheets with thicknesses of 0.8/1/2/3/4/5/6/7/8/9/10mm, etc. Width 1m/1.2m/1.5m

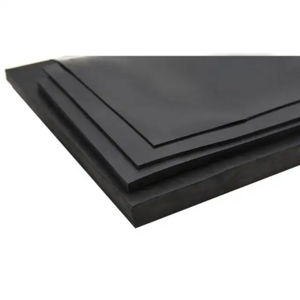

|

Rubber sheet material

|

thickness(mm)

|

width(mm)

|

color

|

hardness

|

||||

|

VMQ Rubber Sheet

|

0.8/1/2/3/4/5/6/7/8/9/10/11/12/13

|

600/800/1000/1200/1400/1500

Commonly used:

(1000/1500)

|

white/ red/ customized

|

60-65 degrees

|

||||

|

NER rubber sheet

|

1-20

|

600/800/1000/1200/1400/1500Commonly used:

(1000/1500) |

black

|

70-75 degrees

|

||||

|

EPDM rubber sheet

|

1-20

|

600/800/1000/1200/1400/1500Commonly used:

(1000/1500) |

black

|

70-75 degrees

|

||||

|

FKM rubber sheet

|

2-10

|

600/800/1000/1200/1400/1500Commonly used:

(1000/1500) |

black

|

70-75 degress

|

||||

|

|

1.0-1.5/2.0/3.0-10.0mm

|

Within 1.2m

|

Mainly white and gray

|

Note: The flame retardant grade of the flame-retardant silicone plate is FV0, and the withstand voltage of the insulating silicone

plate is below 20KV |

||||

Q1: Are you a factory or a trader?

A: We are a manufacturer in the rubber and plastic industry for 15 years.

Q2: Can your company customize all kinds of rubber parts?

A: Yes, our company can process (OEM) flat pads without opening molds.

Q3: Does your company produce both nylon and plastic parts?

A: Yes, we have CNC machining workshop and produce nylon and plastic.

Q4: How long is your usual delivery date?

A: Spot goods can be delivered on the same day, and customized products can take 7-10 working days.

Hot Searches