- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Huaweiguochuang

-

Model Number:

-

HW-T4-50F

-

Number of feeder:

-

50

-

Number of camera:

-

6

-

Number of head:

-

4

-

Guide rail:

-

TBI Linear Guide rail

-

Software:

-

English

-

MAX PCB Area:

-

400*200mm

-

Drive motor:

-

Panasonic Servo Motor

-

Driving mode:

-

TBI ball screw

-

After-sales Service Provided:

-

Online support

Quick Details

-

Weight (KG):

-

280

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

Huaweiguochuang

-

Model Number:

-

HW-T4-50F

-

Number of feeder:

-

50

-

Number of camera:

-

6

-

Number of head:

-

4

-

Guide rail:

-

TBI Linear Guide rail

-

Software:

-

English

-

MAX PCB Area:

-

400*200mm

-

Drive motor:

-

Panasonic Servo Motor

-

Driving mode:

-

TBI ball screw

-

After-sales Service Provided:

-

Online support

Introduction

The machine 50F with the ball screw and servo motor which is more stable and accurate than normal step motor, software designed and developed by our self.

It is available in English. And we will keep updating it. Customers can get updated software regularly

Machine is of high quality with at least one-year warranty, lifetime maintenance.

Feature

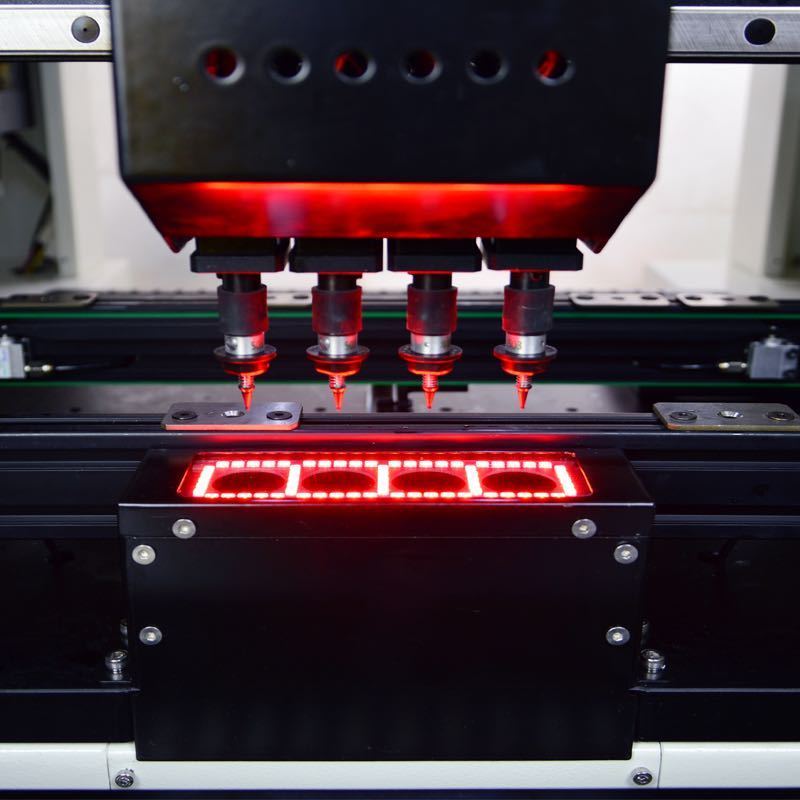

1. SMT pick and place machine with 50 feeders +4 heads adopts Panasonic servo motor to ensure it is stable and accuracy

2. SMT pick and place machine uses imported Straight guide rail +screw Guide can get faster speed and more stable

3. Four mounting heads work together, under 6 cameras inspection come with 50 feeder positions will make machine working more

Part List

1.Pick and place machine:1Set

2.IC fixed support:4Sets (four M5*8, four M5*16)

3.JUKI nozzle:12Pcs (502*2,503*3,504*4,505*2,506*1)

4.Calibration suction nozzle:4PCS

5.Power wire:1PC

6.Fixed foot:4PCS (Diameter 20mm)

7.The keyboard and mouse:1Set

8.Nozzle calibration ink-pad:1Box

9.lubricant:1PC

10.Chassis key:1PC

11.PC:1Set

12.17-inch liquid crystal display:1Set

|

Specification

|

|

|

|

Maximum circuit board area

|

400*200 mm

|

|

|

Number of mounting heads

|

4

|

|

|

Maximum movement range of Z axis

|

20 mm

|

|

|

Maximum mounting rate

|

9,500 PCS/hour

|

|

|

Average mounting rate

|

8,000 PCS/hour

|

|

|

Positioning accuracy

|

0.01 mm

|

|

|

Buffering range of suction nozzle

|

4.5 mm

|

|

|

Power supply

|

220V/110V, 50 Hz

|

|

|

Compressed air:

|

0.6-0.7 Mpa

|

|

|

Average power

|

400 W

|

|

|

Recognition Mode

|

Four Heads Synchronized Recognition

|

|

|

Number of cameras

|

a Mark camera, four high-speed cameras, a high-definition camera

|

|

|

Product weight

|

250KG

|

|

|

PCB access mode

|

automatic Left-in and right-out access, supporting left-right device connection function

|

|

|

Quantity of trays

|

Up to 48 non-feeder feeding components are supported, each of which can specify its coordinates within the mounting range.

|

|

|

Complex speed to mount resistance and Chip

|

6000/CPH

|

|

|

|

0201-40*40mm,Pin spacing 0.3mm

|

|

|

|

Chip(Matching which support electric feeder can mount the 0402,0201)

|

|

|

Quantity of feeders

|

50 PCS

|

|

|

Service motor

|

Panasonic servo motor

|

|

|

Guide rail

|

Taiwan TBI Linear Guide rail

|

|

|

Driving mode

|

Taiwan TBI ball screw

|

|

|

Nozzle Vacuum Source

|

Japan CKD High Speed On-off Vacuum Generator with Vacuum Damage

|

|

|

Minimum air capacity of pump

|

80-120 L/min, volume more than 60 L

|

|

|

Gas quality requirements

|

oil-water separation device, dust filter device, air pressure stabilization device

|

|

|

Dimension

|

900×1140×130mm

|

|

Hot Searches