- Product Details

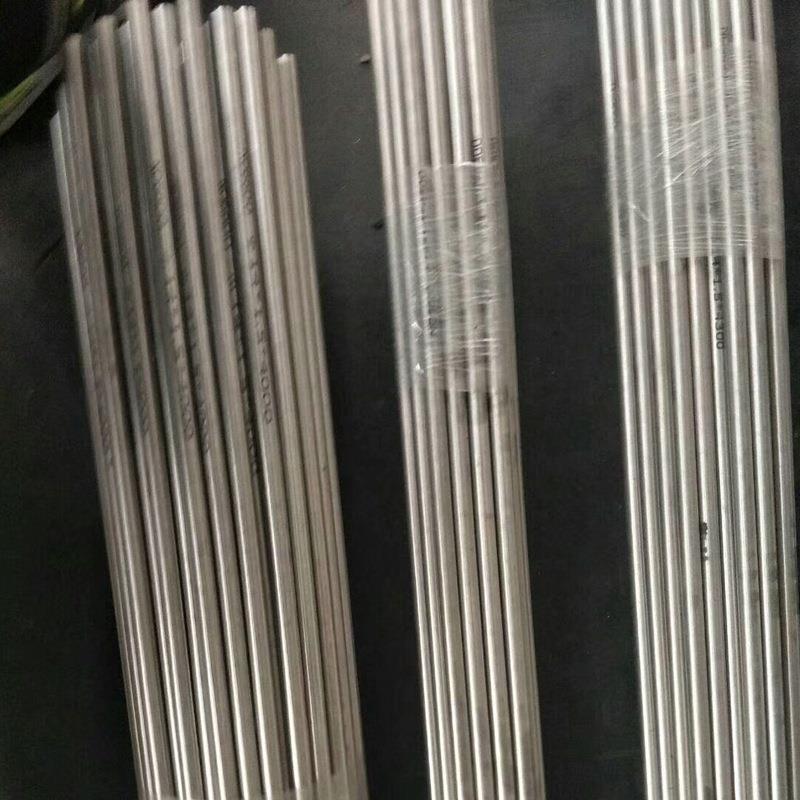

- {{item.text}}

Quick Details

-

Grade:

-

200 Series/300 Series/400series

-

Surface Finish:

-

BA/2B/NO.1/NO.3/NO.4/8K/HL

-

Invoicing:

-

by theoretical weight

-

Place of Origin:

-

American Samoa

-

Brand Name:

-

Sihua

-

Model Number:

-

202 301 304 304L 347 316 316L 430

-

Application:

-

Architecture, Agriculture, Industry, Decoration, Architecture, Agriculture, Industry, Decoration

-

Outer Diameter:

-

50mm

-

Product name:

-

Stainless Steel Pipe

-

Material:

-

200 Series/300 Series/400series

-

MOQ:

-

5 Ton

-

Surface:

-

Polishing, Hair line,Pickling,NO.1,etc

-

Packing:

-

Standard Sea-worthy Packing

-

PAYMENT TERM:

-

30%T/T Advance + 70% Balance

-

Advantage:

-

Strong Corrosion Resistance

-

Technique:

-

Cold Rolled Hot Rolled

Quick Details

-

Type:

-

Seamless/Welded

-

Steel Grade:

-

202 301 304 304L 347 316 316L 430, 400 440 440C 410 316Ti 420 409 409L 317L,, 410 310 310S 0Cr13 1Cr13 3Cr13 309 904L

-

Tolerance:

-

±1%

-

Grade:

-

200 Series/300 Series/400series

-

Surface Finish:

-

BA/2B/NO.1/NO.3/NO.4/8K/HL

-

Invoicing:

-

by theoretical weight

-

Place of Origin:

-

American Samoa

-

Brand Name:

-

Sihua

-

Model Number:

-

202 301 304 304L 347 316 316L 430

-

Application:

-

Architecture, Agriculture, Industry, Decoration, Architecture, Agriculture, Industry, Decoration

-

Outer Diameter:

-

50mm

-

Product name:

-

Stainless Steel Pipe

-

Material:

-

200 Series/300 Series/400series

-

MOQ:

-

5 Ton

-

Surface:

-

Polishing, Hair line,Pickling,NO.1,etc

-

Packing:

-

Standard Sea-worthy Packing

-

PAYMENT TERM:

-

30%T/T Advance + 70% Balance

-

Advantage:

-

Strong Corrosion Resistance

-

Technique:

-

Cold Rolled Hot Rolled

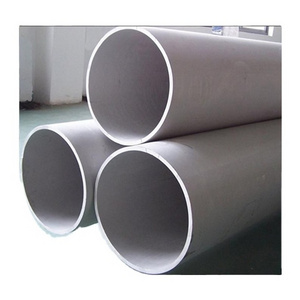

Product Paramenters

Stainless steel pipes are divided into ordinary carbon steel pipes, high-quality carbon structural steel pipes, alloy structural

pipes, alloy steel pipes, bearing steel pipes, stainless steel pipes, and bimetallic composite pipes, coatings and coating pipes for saving precious metals and meeting special requirements. . Stainless steel tubes are available in a wide variety of applications, with different technical requirements and different production methods. The outer diameter of the currently produced steel pipe ranges from 0.1 to 4500 mm and the wall thickness ranges from 0.01 to 250 mm. In order to distinguish the characteristics, the steel pipes are usually classified as follows.

pipes, alloy steel pipes, bearing steel pipes, stainless steel pipes, and bimetallic composite pipes, coatings and coating pipes for saving precious metals and meeting special requirements. . Stainless steel tubes are available in a wide variety of applications, with different technical requirements and different production methods. The outer diameter of the currently produced steel pipe ranges from 0.1 to 4500 mm and the wall thickness ranges from 0.01 to 250 mm. In order to distinguish the characteristics, the steel pipes are usually classified as follows.

|

Product Name

|

Stainless steel pipe

|

|

Standard

|

ASTM AISI DIN, EN, GB, JIS

|

|

Steel Grade

|

200 Series: 201,202

300 Series: 301,304,304L,316,316L,316Ti,317L,321,309s,310s 400 Series: 409L,410,410s,420j1,420j2,430,444,441,436 Duplex Steel: 904L,2205,2507,2101,2520,2304 |

|

Outer Diameter

|

6-2500mm(as required)

|

|

Thickness

|

0.3mm-150mm (as required)

|

|

Length

|

2000mm/2500mm/3000mm/6000mm/12000mm(as required)

|

|

Technique

|

Seamless/Welded

|

|

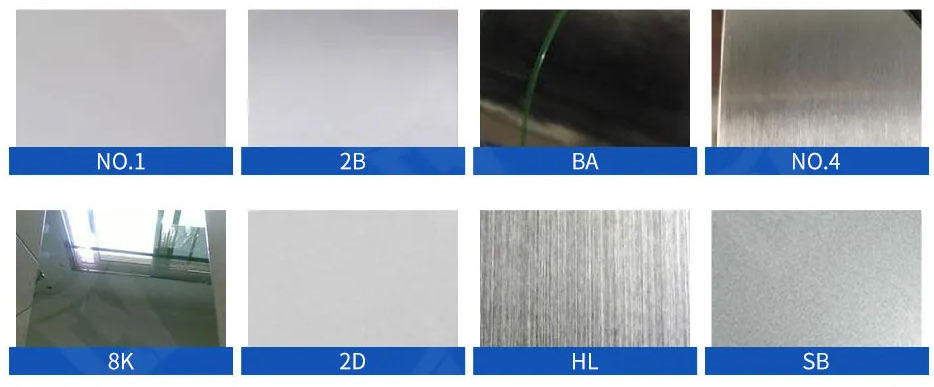

Surface

|

No.1 2B BA 6K 8K Mirror No.4 HL

|

|

Tolerance

|

±1%

|

|

Price Terms

|

FOB,CFR,CIF

|

N0.1: Heat treatment and pickling treatment after hot rolling.

2B: After cold rolling, heat treatment, pickling or similar treatment is carried out, and finally it is smoothed to obtain proper gloss.

2D: Matte surface treated with heat treatment,pickling or similar treatment after cold rolling.

3#: 100~200# The product is polished by grinding belt.

4# :150~180# The product is polished by grinding belt.

HL: Polishing of abrasive materials with appropriate particle size to

Product advantage

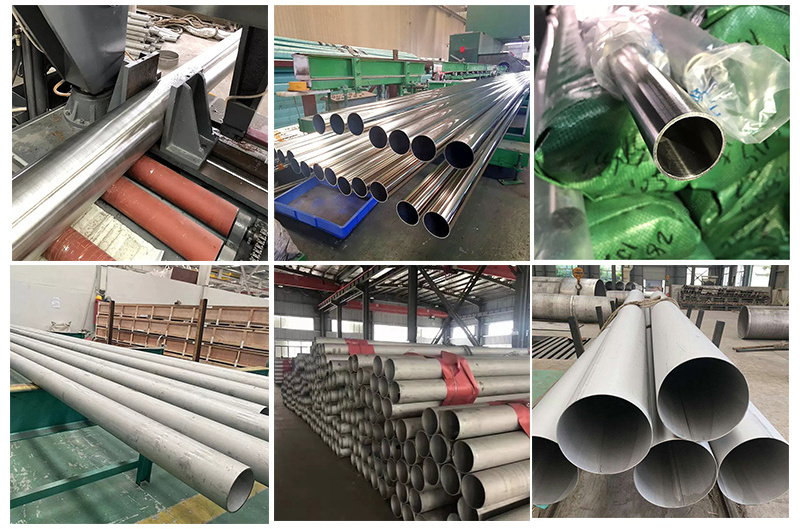

Stainless steel welded pipe production process:

Raw materials - slitting - welding pipe - trimming - polishing - inspection

(printing) - packaging - shipping (into the warehouse) (decorative welded pipe). Raw materials--striping--welding pipe--heat

treatment--correction--straightening--trimming--pickling--hydraulic pressure test--inspection (printing)-packaging--shipping

(warehouse) (Pipe pipe industrial piping pipe).

(printing) - packaging - shipping (into the warehouse) (decorative welded pipe). Raw materials--striping--welding pipe--heat

treatment--correction--straightening--trimming--pickling--hydraulic pressure test--inspection (printing)-packaging--shipping

(warehouse) (Pipe pipe industrial piping pipe).

Stainless steel pipe is a kind of high toughness pipe with excellent shock resistance. Its low temperature embrittlement

temperature is very low, can be used safely in the temperature range of -60~100℃, in winter construction, due to the good impact resistance of the material, it is not easy to crack the pipeline, the pipeline is deformed by external impact and does not affect the pipeline operation, and the corrosion resistance level is strong and efficient to ensure the pipeline safety.

temperature is very low, can be used safely in the temperature range of -60~100℃, in winter construction, due to the good impact resistance of the material, it is not easy to crack the pipeline, the pipeline is deformed by external impact and does not affect the pipeline operation, and the corrosion resistance level is strong and efficient to ensure the pipeline safety.

The stainless steel pipe has a smooth and flat surface, which is not easy to accumulate scale. The smooth and flat performance and non-adhesive properties ensure that the pipeline has a stronger transportation level than traditional pipes, and at the same time reduces the pressure loss and transportation energy consumption of the pipeline

Our company

Sihua Steel Group Company Limited is a comprehensive enterprise group integrating steel product sales, after-sales service and domestic and international trade. The company implements ISO9001-2000 quality management system and ISO14001 environmental protection system, and has formed carbon steel and stainless steel products while actively developing diversification, covering pipes, profiles, plates, etc.

Through continuous expansion of production scale, adjustment and optimization of product structure, showing a trend of efficient and sustainable development. With excellent quality and excellent service, all products not only sell well in the domestic market for more than 30 years, but also exported to Russia, Canada, India, Brazil, Southeast Asia and other more than 40 countries and regions, enjoy a high reputation in the international market.

We guarantee complete specifications, timely delivery, superior quality and favorable price. Your unwavering support and growing demand will help us to offer a wider range of high quality products at more competitive prices. Win-win is our eternal pursuit.

Factory production

Product packaging

Good reputation

Customer Photos

Certifications

FAQ

Q: Do you have an after-sales team? Do you have a research and development team?

A: We have a professional after-sales team and a research and development team of 3-5 people.

Q: Can you send me a product catalog?

A: Yes, please leave your contact information and I will send you the latest catalog.

Q: How can I get the most favorable price?

A: Please send us the details of the product,such as material grade, size, etc. Then we will quote you the most favorable price accordingly.

Q: How long is your delivery time?

A: We have ten thousand tons of spot inventory. The delivery time is usually around 3-5 days.

A: We have ten thousand tons of spot inventory. The delivery time is usually around 3-5 days.

Q: How many years have your company been producing this product?

A: We have been in this industry for 15 years, so we can provide you with the most favorable prices and professional services.

Q: What kind of processing can your company do?

A: The batching process involves laser edge grinding,polishing, mechanical processing, inspection of castings, sawing, cutting, surface inspection, drilling, drilling, pressing,forming, grinding, machine edge grinding, packaging, grinding, polishing, and casting. After cleaning, manual edge grinding,packaging, warehousing, electroplating, heat treatment, cutting, and planing.

Hot Searches