- Product Details

- {{item.text}}

Quick Details

-

Certificate:

-

ISO9001:2008 ROHS

-

Delivery time:

-

1-2 Week

-

Samples:

-

Free

-

Brand:

-

Qishen

-

Glass fiber:

-

10-50%

-

Glass fiber content:

-

33%(Customizable

-

Package:

-

25Kg/Bag

-

Quality Certification:

-

IS09001

-

Grade:

-

Injection Grade. Extrusion Grade

Quick Details

-

Place of Origin:

-

Shanghai

-

Brand Name:

-

Qishen

-

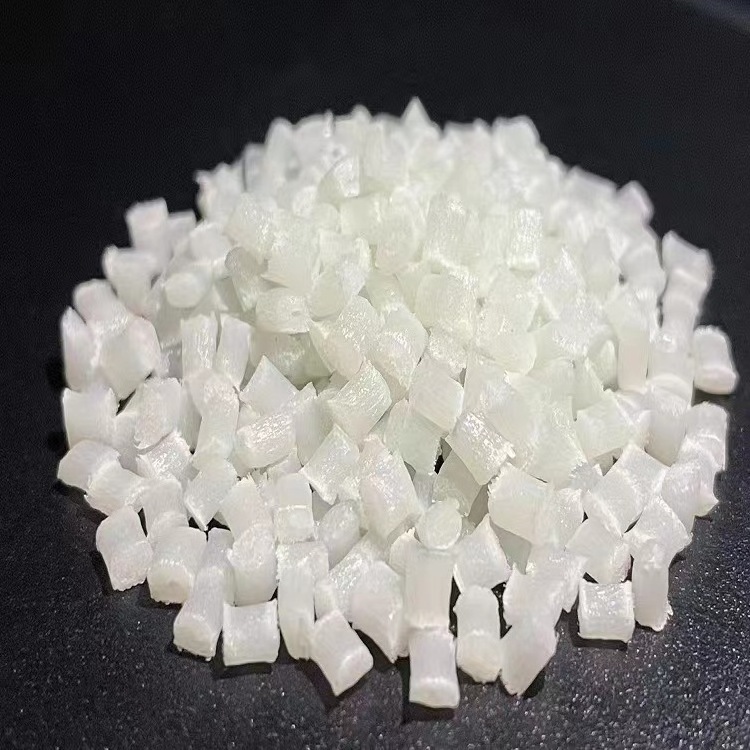

Color:

-

white or customized

-

Certificate:

-

ISO9001:2008 ROHS

-

Delivery time:

-

1-2 Week

-

Samples:

-

Free

-

Brand:

-

Qishen

-

Glass fiber:

-

10-50%

-

Glass fiber content:

-

33%(Customizable

-

Package:

-

25Kg/Bag

-

Quality Certification:

-

IS09001

-

Grade:

-

Injection Grade. Extrusion Grade

Products Description

Nylon 66 has high fatigue strength and steel properties, good heat resistance, low coefficient of friction, good wear resistance,but high moisture absorption and insufficient dimensional stability.

Usually used in medium load, use temperature <100-120 degrees without lubrication or less lubrication conditions of the work of wear-resistant stressed transmission parts.

Features.

1.Excellent mechanical properties. Nylon has high mechanical strength and good toughness.

2. Self-wetting, good friction resistance. Nylon has good self-wetting, small coefficient of friction, thus, as a transmission part of its long service life.

3. Good elasticity, good fatigue resistance, can withstand tens of thousands of times of double flexing.

4. Good corrosion resistance, not mold, not afraid of moth, have the ability to resist alkali, but not acid and oxidizer.

5. Good dyeing performance.

6. Small relative density, only 1.04-1.14, in addition to polyolefin fiber, is the lightest fiber.

Test Report

|

PA66 GF33 Resin Granule

|

Test Method

|

Value

|

Unit

|

|

|

Physical property

|

|

|

|

|

|

Density

|

ASTM D792

|

1.39

|

g/cm³

|

|

|

Shrinkage Flow

|

ASTM D995

|

0.3

|

%

|

|

|

Relative Viscosity

|

ASTM D789

|

59

|

|

|

|

Mechanical behavior

|

|

|

|

|

|

Tensile Strength 23℃

|

ASTM D638

|

210

|

MPa

|

|

|

Tensile Modulus 23℃

|

ASTM D638

|

10400

|

MPa

|

|

|

Elongation 23℃

|

ASTM D638

|

3

|

|

|

|

Flexural Strength 23℃

|

ASTM D790

|

320

|

MPa

|

|

|

Flexural Modulus 23℃

|

ASTM D790

|

8800

|

MPa

|

|

|

Poisson Ratio

|

ASTM E132

|

0.35

|

|

|

|

Shearing Modulus

|

|

3900

|

MPa

|

|

|

Thermal

|

|

|

|

|

|

HDT Unannealed 1.8MPa

|

ASTM D648

|

245

|

℃

|

|

|

HDT 0.45MPa

|

ASTM D648

|

260

|

℃

|

|

|

Melting Temperature

|

ASTM D3418

|

260

|

℃

|

|

|

Electrical properties

|

|

|

|

|

|

Volume Resistivity

|

ASTM D257

|

1E14

|

Ω.cm

|

|

|

Dielectric Strength

|

ASTM D149

|

20

|

KV/mm

|

|

|

Flammability

|

|

|

|

|

|

Flame Rating All Color 0.8mm

|

UL94

|

HB

|

|

|

|

Flame Rating All Color 1.6mm

|

UL94

|

HB

|

|

|

|

Flame Rating All Color 3.2mm

|

UL94

|

HB

|

|

|

More Products

Product Application

Hot Searches