- Product Details

- {{item.text}}

Quick Details

-

Size:

-

50mm/80mm/100mm/150mm/200mm,customized

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HNHONGXIANG

-

Model Number:

-

HX-VD1

-

Viscosity:

-

100%

-

Product name:

-

Vitrified Bond Diamond Grinding Wheel

-

Material:

-

Diamond

-

Process:

-

Hot Press Sintered

-

Advantage:

-

High Efficient

-

Payment Term:

-

TT,PAYPAL

-

MOQ:

-

1 Piece

-

Delivery Time:

-

10-20 Days

-

Diamond bond:

-

Vitrified Bond

-

Keyword:

-

diamond wheels

Quick Details

-

Application:

-

Ferrous Metals, nonferrous metals

-

Shape:

-

Flat-Shaped

-

Hardness:

-

hard

-

Size:

-

50mm/80mm/100mm/150mm/200mm,customized

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HNHONGXIANG

-

Model Number:

-

HX-VD1

-

Viscosity:

-

100%

-

Product name:

-

Vitrified Bond Diamond Grinding Wheel

-

Material:

-

Diamond

-

Process:

-

Hot Press Sintered

-

Advantage:

-

High Efficient

-

Payment Term:

-

TT,PAYPAL

-

MOQ:

-

1 Piece

-

Delivery Time:

-

10-20 Days

-

Diamond bond:

-

Vitrified Bond

-

Keyword:

-

diamond wheels

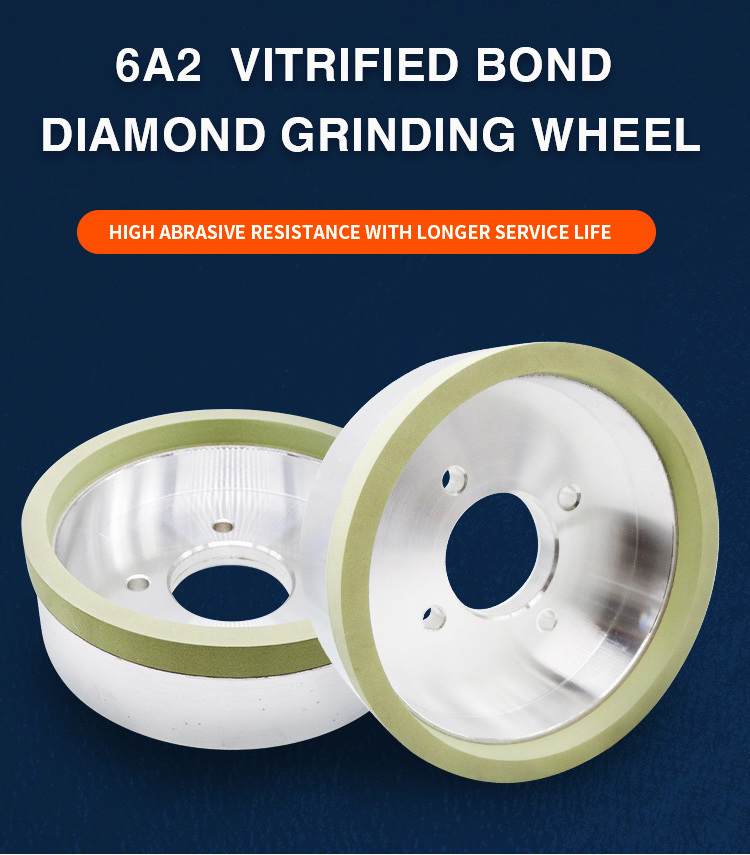

Vitrified Bond Grinding Wheel/Vitrified Bond CBN Grinding Wheel for Crankshaft

Product Advantages

Product Information

|

Size

|

100mm/110mm/125mm/200mm/150mm/250mm/350mm/400mm

|

|

|

Rough grinding

|

W14/W28/W40

|

|

|

Finish Grinding

|

W10

|

|

|

Super Finish Grinding

|

w5/w3.5

|

|

|

other grit be customized upon request

|

|

|

Application

Vitrified Diamond grinding wheel is most commonly employed in the grinding of PCD and PCBN tools, and it also have enabled polycrystalline tool fabricators to obtain excellent surface finishes, quickly and productively. Vitrified grinding wheels can also be used in the fabrication of sapphire, as well as many dense ceramic materials and so on.

The very nature of vitrified bonds allows for the custom tailoring of a grinding wheel structure specific to a customer's material and grinding process, resulting in an efficient grinding process where wheel life and cycle times are optimized for lowest costs and highest work piece quality.

The very nature of vitrified bonds allows for the custom tailoring of a grinding wheel structure specific to a customer's material and grinding process, resulting in an efficient grinding process where wheel life and cycle times are optimized for lowest costs and highest work piece quality.

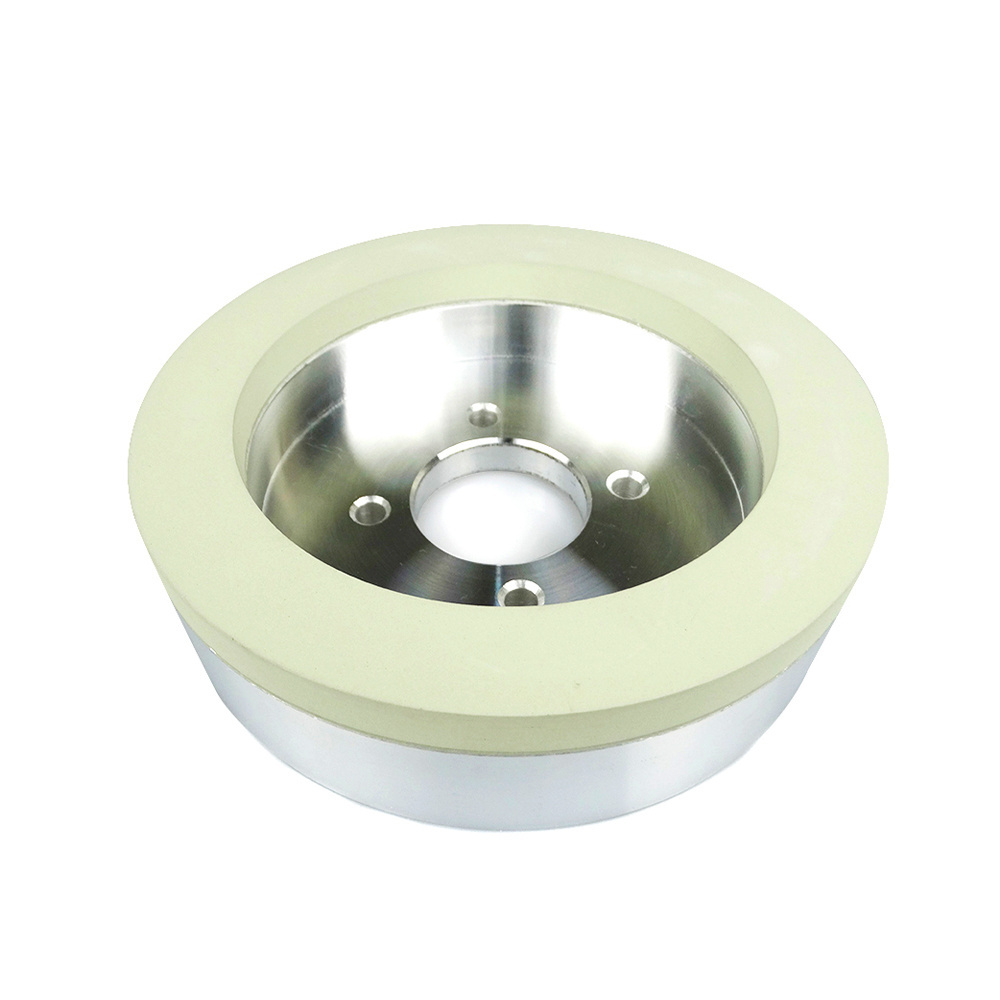

Products Show

Product Praise

Hot Searches