Extreplas®

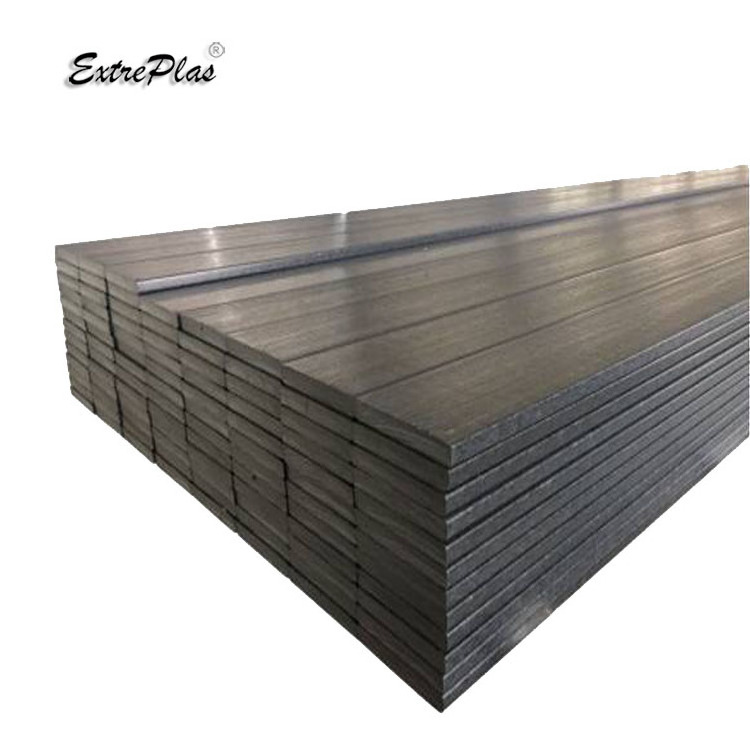

WinStar Superior Series Plastic Lumber is manufactured from post consumer

recycled plastic

which is an alternative to traditional

wood or WPC for your construction projects. Because there is

no wood filler added

during production, you won’t have to worry about

rotting, splintering, water or insect damage, thus plastic lumber can totally replace all the needs of traditional wood and WPC in

the market and perform much better.

- Product Details

- {{item.text}}

Quick Details

-

Design Style:

-

As per client's request

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

Win Star

-

Model Number:

-

Customized

-

Material:

-

PE

-

Thickness:

-

15-300mm

-

Size:

-

140*38, 140*25, 120*30mm

-

Processing Service:

-

Cutting, Moulding

-

Color:

-

teak / brown / cedar / pine / walnut / ocean blue / white

-

Surface:

-

Sanding / Embossing / wood grain

-

Feature:

-

Eco-friendly, Crack and Mildew Resistant

-

Density:

-

0.65 - 0.93 g/cc

-

Certificate:

-

ISO / ASTM

-

MOQ:

-

5 square meter

Quick Details

-

Type:

-

Recycled Plastic Lumber

-

Project Solution Capability:

-

total solution for projects

-

Application:

-

Garden / patio / balcony / yard / terrace

-

Design Style:

-

As per client's request

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

Win Star

-

Model Number:

-

Customized

-

Material:

-

PE

-

Thickness:

-

15-300mm

-

Size:

-

140*38, 140*25, 120*30mm

-

Processing Service:

-

Cutting, Moulding

-

Color:

-

teak / brown / cedar / pine / walnut / ocean blue / white

-

Surface:

-

Sanding / Embossing / wood grain

-

Feature:

-

Eco-friendly, Crack and Mildew Resistant

-

Density:

-

0.65 - 0.93 g/cc

-

Certificate:

-

ISO / ASTM

-

MOQ:

-

5 square meter

Product Description

High Faux Wood Grain HDPE Plastic Plywood Lumber 100% Recycled PE Beam Lumber for Outdoor Furniture and Decks

Superior Series Plastic Lumber

Fiberglass Reinforced Series Plastic Lumber

Extreplas®

WinStar Fiberglass Reinforced Series Plastic Lumber is a structural product engineered with

fiberglass strands to increase strength and rigidity

. Best-suited for projects requiring a wider span and dimensional stability, this recycled plastic lumber product line is ideal for many types of commercial applications. The performance is about twice that of HDPE products.

|

Product Details

|

|

|

||

|

Product Series

|

Features

|

Application

|

||

|

Superior Series Plastic Lumber

|

HDPE ;

100% recyclable;

Replace all the traditional wood or WPC;

Meet customers’ general request;

|

Decorative lumbers;

Signage or marking;

Not bearing requirements;

|

||

|

Fiberglass Reinforced Plastic Lumber

|

HDPE+Fiber glass;

100% recyclable;

Mechanical properties improve 80%+;

Better wood surface;

Perfect choice for high end users;

|

Boardwalks

Public decking

Beams

Bearing requirement

|

||

Multiple Colors optional and color custom service is also available.

|

Common Specification Sheet for Plastic Lumber

|

|

|

|

|

||||

|

Type

|

Metric (True Size)

|

|

Imperial (True Size)

|

|

||||

|

|

Width

(mm)

|

Thickness

(mm)

|

Width

(inch)

|

Thickness

(inch)

|

||||

|

Decks

|

140

|

25

|

5 1/2

|

1

|

||||

|

|

120

|

35

|

4 5/7

|

1 2/5

|

||||

|

Outdoor Furniture

|

65

|

15

|

2 3/5

|

3/5

|

||||

|

|

96

|

15

|

3 4/5

|

3/5

|

||||

|

|

70

|

25

|

2 4/5

|

1

|

||||

|

|

38

|

15

|

1 1/2

|

3/5

|

||||

|

|

38

|

38

|

1 1/2

|

1 1/2

|

||||

|

|

76

|

38

|

3

|

1 1/2

|

||||

|

|

120

|

35

|

4 5/7

|

1 1/2

|

||||

|

Fences

|

100

|

100

|

4

|

4

|

||||

|

|

75

|

75

|

3

|

3

|

||||

|

|

38

|

15

|

1 1/2

|

3/5

|

||||

|

|

65

|

15

|

2 3/5

|

3/5

|

||||

|

|

96

|

15

|

3 4/5

|

3/5

|

||||

|

|

70

|

15

|

2 4/5

|

3/5

|

||||

|

Golf

|

300

|

15

|

11 4/5

|

3/5

|

||||

|

|

38

|

38

|

1 1/2

|

1 1/2

|

||||

|

|

75

|

75

|

3

|

3

|

||||

Product Application

Extreplas®

Win Star HDPE plastic lumbers replace wood and WPC for outdoor furniture. Such as Garden furniture, landscaping, boardwalks, decking and flooring, fencing, posts and bollards, dustbins, flower boxes, Jetties and any other outdoor applications.

Product Advantages

Our Purpose & Social Responsibility

Our purpose is to make a world with

No Plastic Waste

and Protect

Forest System!

Please use recycled plastic product and take responsibility for the impact plastic waste has on our environment and reduce felling of trees !

Much of the planet is swimming in discarded plastic, which is harming animal and human health.

If not effectively prevented, our mother planet will be destroyed gradually.

Because of that human fell away too many trees and the industrial emission massive pollutant cannot obtain properly processing, world environment and climate becoming worse and worse dramatically.

Packing & Delivery

The whole production process is under the strict control of the quality inspection department, and the products are of high

quality, safe loading and delivery.

quality, safe loading and delivery.

Leading Time: Samples 2-3 days ; Bulk Production 15 days.

Shipping Method: By ship or air according to client’s actual need.

Shipping Method: By ship or air according to client’s actual need.

Company Introduction

⭐ Win Star Plastic Co., Ltd has been specialized in recycled plastic field since 1999.

⭐ Main Products: Recycled plastic lumbers, marine fenders etc. More categories of products will be developed soon.

⭐ OEM&Customization service available.

⭐ We are integrated with research, development, manufacture and sale.

⭐ Quality Assurance: 13 technical patents; ASTM qualified; ISO9001 : 2008.

⭐ Main market: North America, Europe.

⭐ Main Products: Recycled plastic lumbers, marine fenders etc. More categories of products will be developed soon.

⭐ OEM&Customization service available.

⭐ We are integrated with research, development, manufacture and sale.

⭐ Quality Assurance: 13 technical patents; ASTM qualified; ISO9001 : 2008.

⭐ Main market: North America, Europe.

Company Overview

Model Machine

Show Room

Manufacturing Process

Our Honor

With over 20 years of development, Win Star possesses 13 technical patents and is honored with

New High-tech Enterprise.

Our products passed ISO9001 and meet the standard of ASTM which received highly praise from customers all over the world.

Customer Feedback & Exhibition

FAQ

Q: What is recycled plastic timber made from?

A: Our recycled plastic lumber contains over 90% recycled HDPE with little activities (such as anti-UV and anti-aging).

A: Our recycled plastic lumber contains over 90% recycled HDPE with little activities (such as anti-UV and anti-aging).

Q: Where can this product be applied?

A: Outdoor deckings, signpost and furniture. Anywhere traditional wood or WPC lumber are used, we can perfectly replace them.

A: Outdoor deckings, signpost and furniture. Anywhere traditional wood or WPC lumber are used, we can perfectly replace them.

Q: What’s the usage life of HDPE plastic lumber?

A: Usage life is 40 to 50 years as it protects against rotting, cracking, splitting and peeling.

A: Usage life is 40 to 50 years as it protects against rotting, cracking, splitting and peeling.

Q: Is your plastic lumber 100% anti-corrosion?

A: Yes, compare to WPC lumber, our product contain no organic ingredient like wood fillers. So no mildew will grow.

A: Yes, compare to WPC lumber, our product contain no organic ingredient like wood fillers. So no mildew will grow.

Q: What is the lowest temperature can be used of the product?

A: Due to superior weather ability, product can be used at -70℃

A: Due to superior weather ability, product can be used at -70℃

Q: What type of tools do I need to install?

A: Plastic timber is just as easy to work as wood, it can be cut, sawed, drilled, routed, nailed, or sanded with standard wood working tools, including pneumatic nail guns and CNC routers.

A: Plastic timber is just as easy to work as wood, it can be cut, sawed, drilled, routed, nailed, or sanded with standard wood working tools, including pneumatic nail guns and CNC routers.

Q: Will there be color difference between each batch of production?

A: Color between each batch of production can be slightly different because raw material, operation temperature and color master. But we can guarantee each time production color consistence.

A: Color between each batch of production can be slightly different because raw material, operation temperature and color master. But we can guarantee each time production color consistence.

Q: What colors are available?

A: Colors are optional from dark to light. Regular colors are red, dark green, brown, black, grey.. Color custom service is available as well!

A: Colors are optional from dark to light. Regular colors are red, dark green, brown, black, grey.. Color custom service is available as well!

Hot Searches