- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZODE

-

Voltage:

-

380V 50HZ

-

Power:

-

19

-

Dimension(L*W*H):

-

11*3.5*1.8M

-

Weight:

-

1000 kg

-

Marketing Type:

-

New Product 2021

-

Name:

-

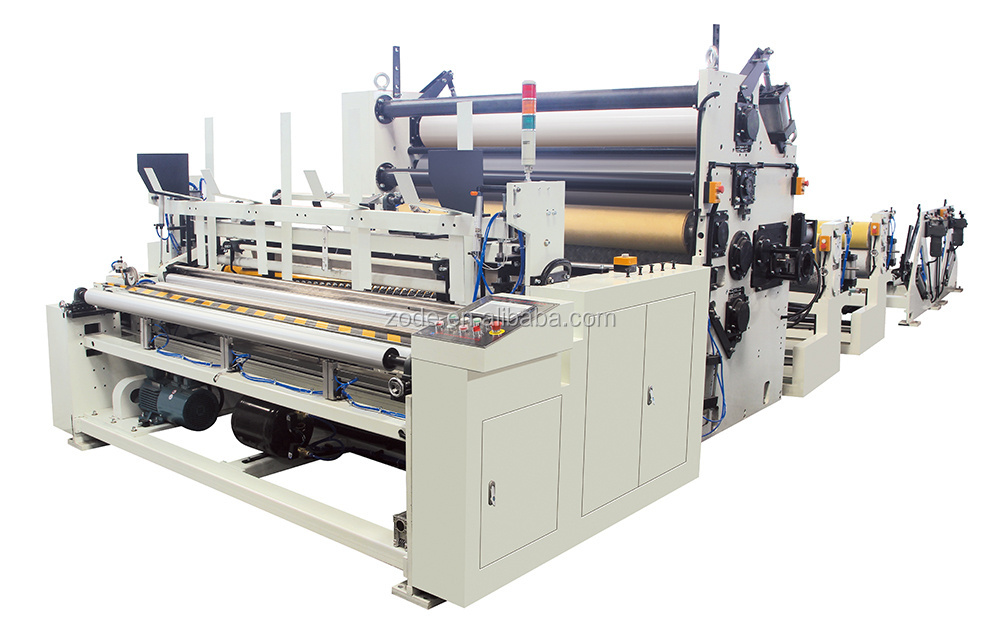

Toilet Paper Slitting and Rewinding Machine

-

Finished Products:

-

Toilet Tissue Paper Roll and kitchen towel

-

Raw material:

-

Jumbo roll, parent roll

-

Capacity:

-

2-3 tons/day

-

Model:

-

ZD-N2L

-

Type:

-

Tissue machine

-

Working speed:

-

180-250m/min

-

Parameter setting:

-

Touch screen

-

Embossing unit:

-

Steel to rubber embossing unit

-

Glue lamination unit:

-

Available

Quick Details

-

Production Capacity:

-

180 m/min

-

Product Type:

-

Toilet Tissue rewinding machine

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

ZODE

-

Voltage:

-

380V 50HZ

-

Power:

-

19

-

Dimension(L*W*H):

-

11*3.5*1.8M

-

Weight:

-

1000 kg

-

Marketing Type:

-

New Product 2021

-

Name:

-

Toilet Paper Slitting and Rewinding Machine

-

Finished Products:

-

Toilet Tissue Paper Roll and kitchen towel

-

Raw material:

-

Jumbo roll, parent roll

-

Capacity:

-

2-3 tons/day

-

Model:

-

ZD-N2L

-

Type:

-

Tissue machine

-

Working speed:

-

180-250m/min

-

Parameter setting:

-

Touch screen

-

Embossing unit:

-

Steel to rubber embossing unit

-

Glue lamination unit:

-

Available

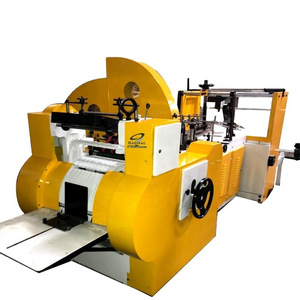

Factory hot sale product machinery in taiwan tissue making machine to make toilet paper

ZD-N2L

Full-automatic high-speed rewinding and perforated toilet paper machine, This equipment is to perforate and cut the raw paper into various sizes according to the requested. The finished product is neat, in good order and with equality tension. It has the feature of compact structure, easy and stable operation, less electricity consumption and covers a small area of 8.4 m? . The highest production speed is 150-250m/min. This equipment is adjustable to meet the requested finished product. This model is the ideal equipment for paper making factory and paper processing factory.

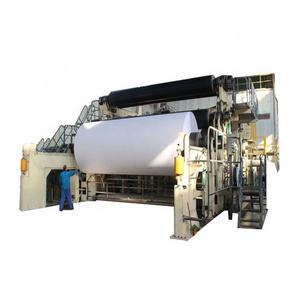

This equipment can process raw paper of 1.2m 1.75m 1.95m 2.15m 2.35m 2.55m 2.75m in width.

Features

1. At the time of acceleration and speed reduction, the synchronization between the host and the rear frame, embossing, etc. is good, and the rewinding speed is improved. The production speed is increased from 0-180 m/min to 0-230 m/min.

2. The main engine and embossing, embossing, and rear frame no longer require mechanical transmission such as transmission chains and speed reduction boxes. Reduce the time of repair and machine adjustment greatly.

3. Using PLC asynchronous servo control, following the main motor from the motor, the paper tension of the rewinding process is stable. Avoiding the paper paper wrinkle caused by the opening and stopping of the chain drive, the pitch fluctuation of the punch, and the tightening of the paper ball are not the same defects.

4. The tension adjustment between the functional units is convenient and quick through the touch screen setting parameters.

5. The paper backing frame adopts a wallboard structure(30mm) and is solid and beautiful. Leaving the bottom of the machine empty is conducive to the cleaning of paper dust.

Parameters

| Model | 1400mm, 1500mm, 1800mm, 2000mm,2200mm,2800mm, 2900mm, 3000mm |

|

Jumbo roll width |

1350mm, 1450mm, 1750mm, 1930mm,2150mm,2750mm,2850mm, 2950mm |

|

Jumbo roll diameter |

≤ 1200mm ( other size to be specified ) |

|

Jumbo roll core size |

Φ76mm ( other size to be specified ) |

|

Finished roll diameter |

Φ 60-130mm(Tightness is adjustable) |

|

Finished roll core diameter |

Φ 32-50mm |

|

Perforation pitch |

Standard size: 110mm(Adjustable) |

|

Perforation |

4PCS sprial upper perforation knives,improve the durability |

|

Rewind type |

Automatic rewinding machine |

|

Parameter set |

Touch Screen HMI |

|

Rewind system |

With core and coreless integrated |

| Control system | Siemens PLC,inverter,etc. |

| Machine speed | 200-250m/min |

|

Backstand |

1-4 ply (to be confirm by client),independent drive |

|

Edge embossing unit |

Steel to steel |

|

Glue Lamination unit |

Available (to be confirm by client) |

|

Embossing unit |

Steel to steel, steel to rubber (to be confirm by client) |

Nonstop rewinder production line

Facial tissue production line

1)Inside package is plastic film, outside is wooden or plywood case

2)Full automatic instant porridge machine packaging is based on the customers' need).

3)Only plastic film nude packing with wooden pallet.

4)We can supply fumigation package and certificate.

5)Shipping, train, express or upon clients' demands.