- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Motor:

-

SIEMENS Brand

-

Bearing brand:

-

NSK

-

Usage:

-

Film Agglomerator, granulator, pelletizing line

-

Material of barrel:

-

Stainless steel

-

Capacity:

-

100-800kg/h

-

Materials of Cylinder:

-

Stainless Steel 304

-

Motor Power::

-

22-160kw

-

Application:

-

fiber agglomerator / woven bags agglomerator

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HORSERIDER Machinery

-

Weight (KG):

-

2000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Motor:

-

SIEMENS Brand

-

Bearing brand:

-

NSK

-

Usage:

-

Film Agglomerator, granulator, pelletizing line

-

Material of barrel:

-

Stainless steel

-

Capacity:

-

100-800kg/h

-

Materials of Cylinder:

-

Stainless Steel 304

-

Motor Power::

-

22-160kw

-

Application:

-

fiber agglomerator / woven bags agglomerator

-

Certification:

-

CE ISO

Product Description

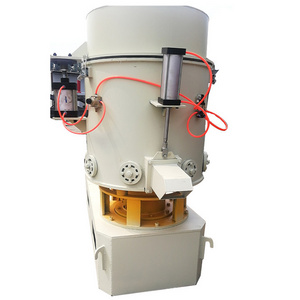

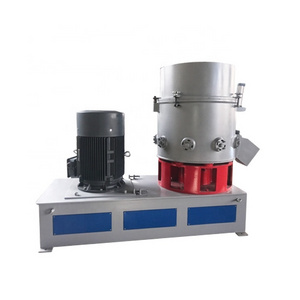

Plastic Agglomerator

PRODUCT INTRODUCTION

GHX plastic Agglomerator can

directly make waste plastic films and other products less than 2mm wall thickness into granules.

It is suitable to

agglomerate the waste products or films made of soft PVC, HDPE, LDPE, PP and other thermo plastics

.

WORKING PRINCIPLE

When the waste plastic is supplied into the chamber of such machine, it will be cut into smaller chips due to the crushing function of the rotating knife and fixed knife. During the crushing processing, the material that soaked up lots heat from the frictional movement of material being crushing and the material will be going to become semi-plasticizing state. The particles will stick with each other due to the function of plasticization. Before it sticks each other completely, the cold water pre-prepared is sprayed into the crushed material. The water will be evaporated off quickly and the surface temperature of crushed material drop down quickly. So the crushed material will become small particles or granules.

ADVANTAGE

----It is easy to recognize the particles by different size and can be colored by using of color agent being putted into the container during the crushing processing.

----The particles can be used for extrusion or injection mould machine directly. Also can be further pelletized for some advanced requirements.

----This machine is

qualified with certificate ISO9001:2000 and CE certificate

.

----

High quality stainless steel 304 makes the machine more durable.

----

Provide comprehensive installation and after-sales service to solve all your problems.

PRODUCT PARAMETERS

|

Model number

|

Motor Power(KW)

|

Capacity (KG/h)

|

Weight(KG)

|

Machine dimension(mm)

|

Fixing blade

|

Rotating blade

|

Main blades speed(r/min)

|

|

GSL-100

|

37

|

100

|

1000

|

1700*750*1500

|

6

|

2

|

1050

|

|

GSL-200

|

55

|

150

|

1200

|

1700*850*1500

|

6

|

2

|

1000

|

|

GSL-300

|

75

|

200

|

1800

|

2000*850*1600

|

8

|

2

|

950

|

|

GSL-500

|

90

|

300

|

2500

|

2300*950*1700

|

8

|

4

|

750

|

|

GSL-600

|

90-110

|

400

|

2700

|

2300*1100*1750

|

8

|

4

|

750

|

|

GSL-800

|

132

|

550

|

3000

|

2500*1250*1800

|

8

|

4

|

750

|

PRODUCT

PICTURE

Related Products

Hot Searches