- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

6600*1900*2500mm

-

Weight:

-

4200 KG, 4200kg

-

Print Dimension:

-

230-1000mm

-

Max. Printing Material Width:

-

800mm

-

Max. Printing Width:

-

760mm

-

Printing Length Range:

-

230-1000mm

-

Printing Speed:

-

5-100m/min

-

Register Precision:

-

≤+0.20mm

-

Thickness Of Plate:

-

2.28mm+0.38mm

-

Machine Power:

-

16kw

-

Dimensions:

-

6600x1900x2500mm

Quick Details

-

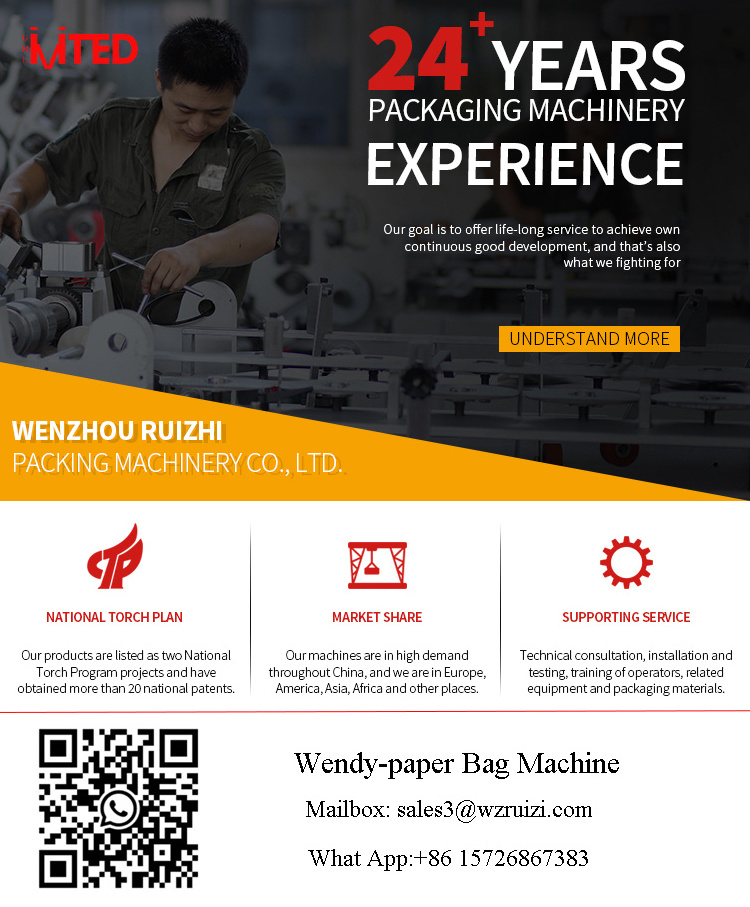

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MTED

-

Voltage:

-

16kw

-

Dimensions(L*W*H):

-

6600*1900*2500mm

-

Weight:

-

4200 KG, 4200kg

-

Print Dimension:

-

230-1000mm

-

Max. Printing Material Width:

-

800mm

-

Max. Printing Width:

-

760mm

-

Printing Length Range:

-

230-1000mm

-

Printing Speed:

-

5-100m/min

-

Register Precision:

-

≤+0.20mm

-

Thickness Of Plate:

-

2.28mm+0.38mm

-

Machine Power:

-

16kw

-

Dimensions:

-

6600x1900x2500mm

Enterprise Exhibitor Information

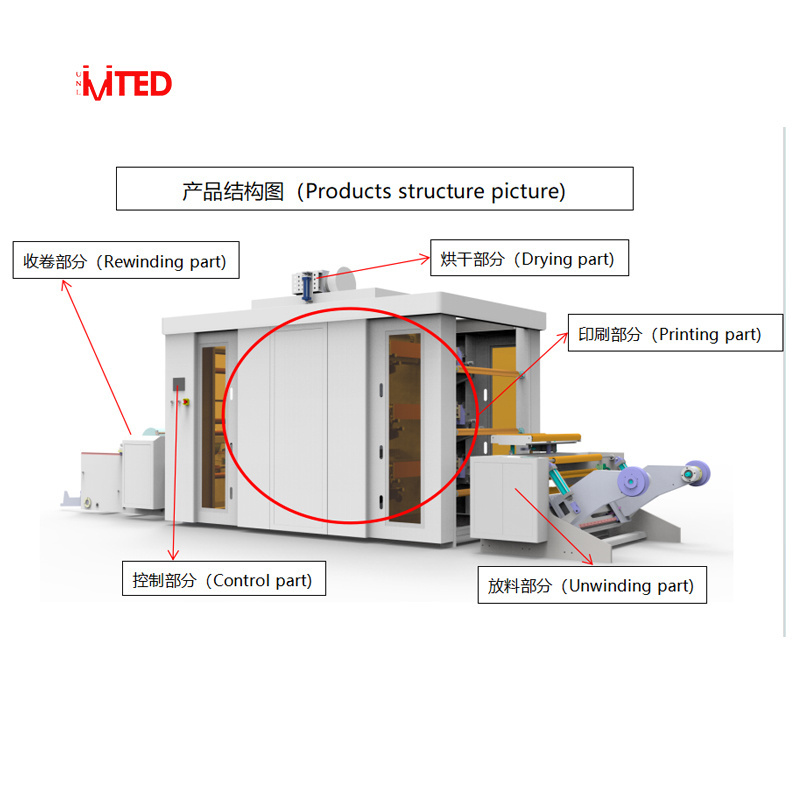

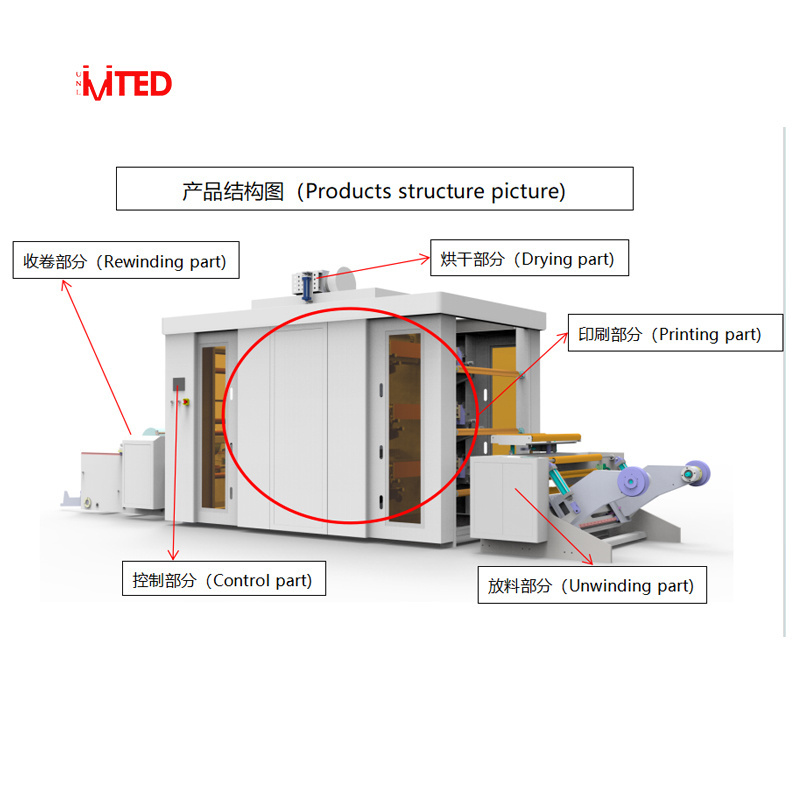

Products Description

CONTROL PART

1.Main motor frequency control,power

2.PLC touch screen control the whole machine

2.Reduce motor separate

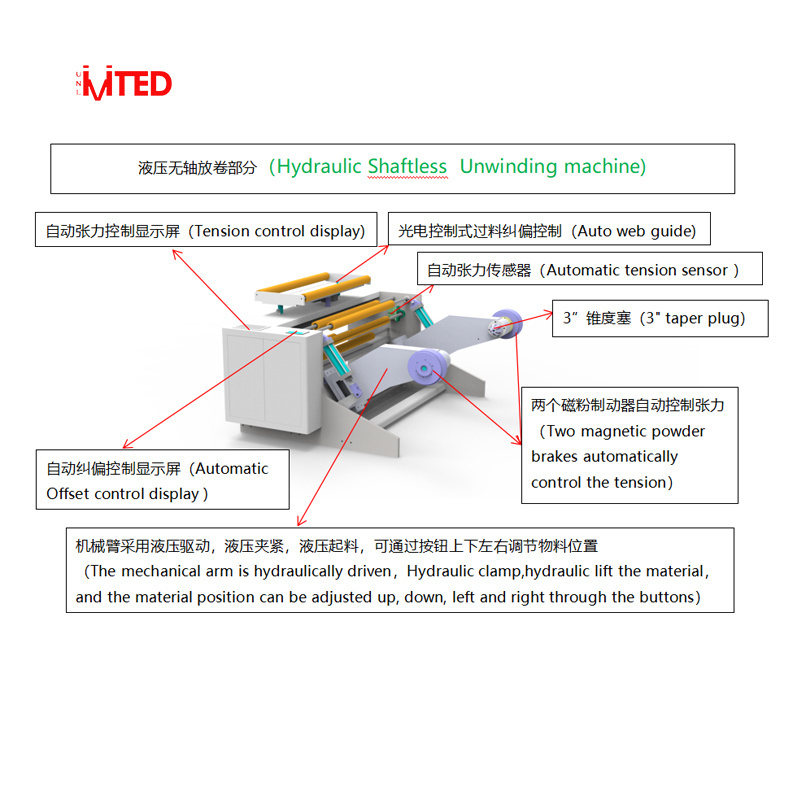

UNWINDING PART

1.Single work station

2.Hydraulic clamp,hydraulic lift the material , hydraulic control the unwinding material width,it can adjust left and right movement.

3.Magnetic powder brake auto tension control.

4.Auto web guide

PRINTING PART

1.Pneumatic lifting and lowing printing plate cylinders auto lifting plate cylinder when the machine is stopped. After that can run ink automatically. When the machine is opening,it will make alarm to start the auto lowering plate printing cylinder.

2.Inking with ceramic anilox chambered doctor blade ,ink pump circulation

3.High precision planetary gear oven 360°circulation longitudinal register

4.±0.20mm transverse register

5.Adjust inking press and printing pressure press by manual

REWINDING PART

1.Back to back rewinding

2.Pneumatic tension control

3.2.2kw motor,vector frequency conversion control

4.3 inch air shaft

5.Hydraulic lowering the material

Enterprise Advantage

We will send technician to your factory to install the machine, and teach your workers to use it

Exhibition

Product packaging

FAQ

Q: Are you a factory or trading company?

A:We are a factory, established in 2003, with a professional team to solve various problems of environmentally friendly paper bags for you

Q: How does your factory do regarding quality control?

A: We have a professional QC department in charge of products' quality.

Q: How long is the warranty period?

A: 12 months calculated from the date of shipment from our factory.During warranty period, except the artificial factor, the spares are free to replace,beyond the warranty time, the buyer needs to pay the spare charge and shipping cost.

Q: How to install the machine?

A: We will send technician to your factory to install the machine, and teach your workers to use it. You pay all related costs, including visa charge, double-way tickets, hotel, meals, and technician salary.

Q: Where is your factory located? How can we visit there?

A: Our factory is located in WENZHOU city,. We will provide transporation service during your visit at our factory.

Q: What information should I let you know if I want to get a quotation?

A: First, Paper raw material: Reel paper or Sheet Paper. Second, sizes of the paper bag, thickness of paper.

Send sample bag picture if available. Then we will recommend the right machine to you!

Hot Searches