- Product Details

- {{item.text}}

Quick Details

-

Power:

-

45KW

-

Dimension(L*W*H):

-

2800*1700*1400mm

-

Weight:

-

3000 kg

-

Product name:

-

Automatic Egg Tray Making Machine

-

Finished Products:

-

Egg Tray Egg Carton

-

Application:

-

Paper Egg Tray Moulding

-

Raw material:

-

Waste Paper Wood Pulp

-

Keyword:

-

Egg Tray Forming Machine

-

Function:

-

Produce Paper Tray

-

Machine type:

-

Egg Tray Molding Machine

-

Advantage:

-

High Effiency

-

Color:

-

Customized Color

Quick Details

-

Production Capacity:

-

1000-7000pcs/h

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220/380V

-

Power:

-

45KW

-

Dimension(L*W*H):

-

2800*1700*1400mm

-

Weight:

-

3000 kg

-

Product name:

-

Automatic Egg Tray Making Machine

-

Finished Products:

-

Egg Tray Egg Carton

-

Application:

-

Paper Egg Tray Moulding

-

Raw material:

-

Waste Paper Wood Pulp

-

Keyword:

-

Egg Tray Forming Machine

-

Function:

-

Produce Paper Tray

-

Machine type:

-

Egg Tray Molding Machine

-

Advantage:

-

High Effiency

-

Color:

-

Customized Color

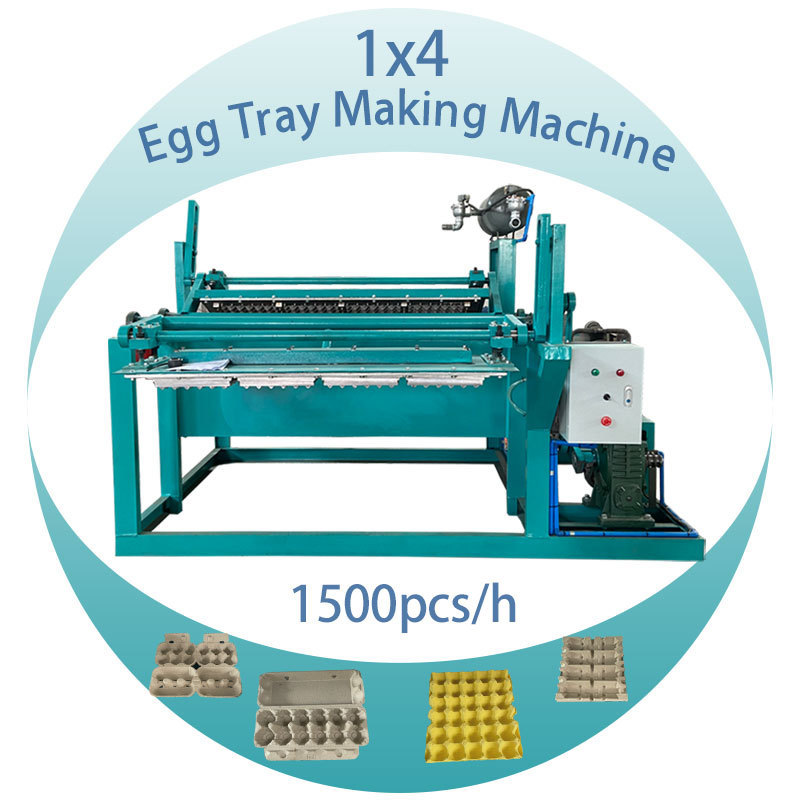

Products Description

Automatic egg box machine waste pulp paper recycle line egg tray making machine

The pulp molding system can use all kinds of waste paper to produce high quality molded fibre products. Such as, egg trays, egg boxes, apple trays, meat portion trays, vegetable portion trays, fruit portion trays, strawberry punnets, kidney trays, wine packs, can trays, seed pots, seed cubes, etc.

Product Paramenters

|

Machine Model

|

1*3/1*4

|

3*4/4*4

|

4*8/5*8

|

5*12/6*8

|

|

Yield(p/h)

|

1000-1500

|

2500-3000

|

4000-6000

|

6000-7000

|

|

Waste Paper(kg/h)

|

80-120

|

160-240

|

320-400

|

480-560

|

|

Water(kg/h)

|

160-240

|

320-480

|

600-750

|

900-1050

|

|

Electricity(kw/h)

|

36-37

|

58-78

|

80-85

|

90-100

|

|

Workshop Area

|

45-80

|

80-100

|

100-140

|

180-250

|

|

Drying Area

|

No need

|

216

|

216-238

|

260-300

|

Our Advantages

High precision servo motor drive,high efficiency and energy-saving drying line.

1,Use precision reducer servo motor forming and transferring to ensure smiith and fast operation.

2,Use absolute encoder to achieve accurate correction.

3,The use of bronze casting static and dynamic ring structure is more suitable for product dewatering process.

4,The use of mechanical structure to ensure that the mold close on both sides evenly.

5,Large capacity; Water content is low;Save the cost of drying.

1,Use precision reducer servo motor forming and transferring to ensure smiith and fast operation.

2,Use absolute encoder to achieve accurate correction.

3,The use of bronze casting static and dynamic ring structure is more suitable for product dewatering process.

4,The use of mechanical structure to ensure that the mold close on both sides evenly.

5,Large capacity; Water content is low;Save the cost of drying.

The raw materials are mainly from various pulp boards such as reed pulp, straw pulp, slurry, bamboo pulp and wood pulp, and waste paperboard, waste paper box paper, waste white paper, paper mill tail pulp waste, etc. Waste paper, widely sourced and easy to collect. The required operator is 5 people/class: 1 person in the pulping area, 1 person in the molding area, 2 people in the cart, and 1 person in the package.

Details Images

Hot Searches