- Product Details

- {{item.text}}

Quick Details

-

Application:

-

road construction, road construction

-

Design Style:

-

geogrid

-

Place of Origin:

-

China

-

Brand Name:

-

Schiebel

-

Model Number:

-

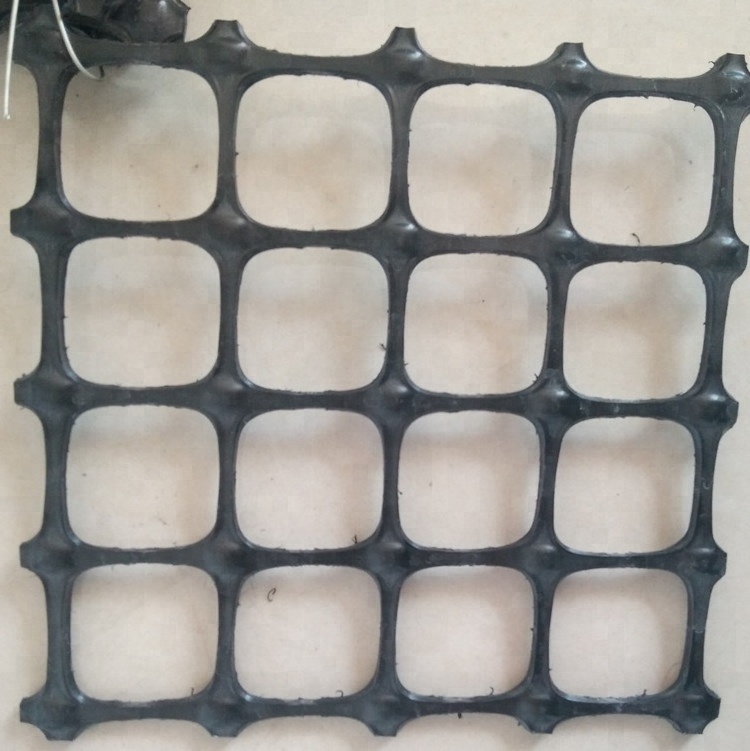

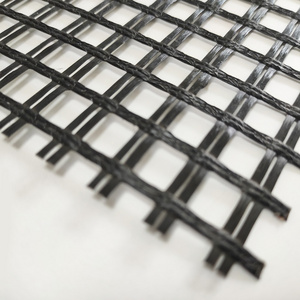

TGSG50-50

-

Color:

-

Black

-

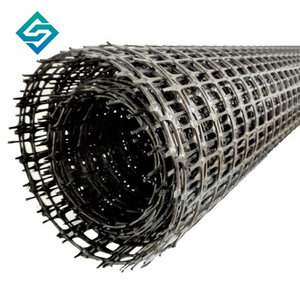

product size:

-

3.95mx50m

-

Material:

-

PP

-

Tensile strength(MD):

-

≥50KN

-

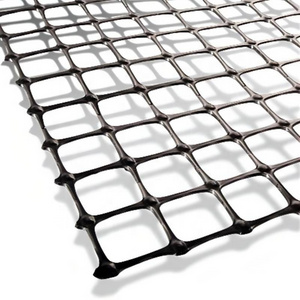

Mesh size:

-

40mmx40mm

-

Tensile strength(CD):

-

≥50KN

-

Elongation at break(MD):

-

≤15%

-

Elongation at break(CD):

-

≤13%

-

Product name:

-

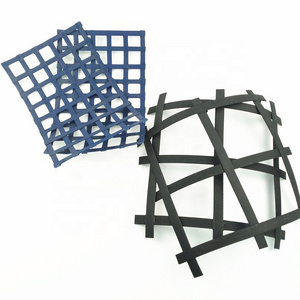

Plastic biaxial geogrid

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

NONE

-

Application:

-

road construction, road construction

-

Design Style:

-

geogrid

-

Place of Origin:

-

China

-

Brand Name:

-

Schiebel

-

Model Number:

-

TGSG50-50

-

Color:

-

Black

-

product size:

-

3.95mx50m

-

Material:

-

PP

-

Tensile strength(MD):

-

≥50KN

-

Mesh size:

-

40mmx40mm

-

Tensile strength(CD):

-

≥50KN

-

Elongation at break(MD):

-

≤15%

-

Elongation at break(CD):

-

≤13%

-

Product name:

-

Plastic biaxial geogrid

Plastic biaxial geogrid is made of high polymer through extrusion, board, punching process and then lengthwise and transversely stretching. The material has great tensile strength in both the longitudinal and transverse directions. This structure also provides an ideal interlocking system for the more effective force bearing and diffusion in the soil, adapting to large-area permanent bearing. Foundation reinforcement.

Since the polymer of the two-way plastic geogrid is realigned and oriented along with the heating extension process, the bonding force between the molecular chains is strengthened, and the strength is improved. Its elongation is only 10% to 15% of the original board. If an anti-aging material such as carbon black is added to the geogrid, it can have good durability such as acid resistance, alkali resistance, corrosion resistance and aging resistance.

The two-way plastic geogrid is suitable for reinforcement of various dams and subgrades, protection of slopes, reinforcement of cave walls, and reinforcement of permanent foundations such as large airports, parking lots and terminal yards.

(1).Two-way plastic geogrid is used to increase the bearing capacity of the road (ground) base and extend the service life of the road (ground) base.

(2).The two-way plastic geogrid is used to prevent the road (ground) surface from collapsing or cracking, and to keep the ground beautiful and tidy.

(3).Two-way plastic geogrid is convenient for construction, saving time, labor, shortening construction period and reducing maintenance costs.

(4).Two-way plastic geogrid is used to prevent cracks in the culvert.

(5).Two-way plastic geogrid is used to strengthen the slope and prevent soil erosion.

(6).Two-way plastic geogrid is used to reduce the thickness of the cushion and save cost.

(7).The two-way plastic geogrid is used to support the stable greening environment of the grass planting mat.

Main Features of two-way plastic geogrid

(1). High strength, small creep, adapt to various environmental soils, can fully meet the use of high retaining walls in high-grade highways.

(2). It can effectively improve the interlocking and biting of the reinforced bearing surface, greatly enhance the bearing capacity of the foundation, effectively restrain the lateral displacement of the soil, and enhance the stability of the foundation.

(3).Compared with the traditional grille, it has the characteristics of high strength, strong bearing capacity, corrosion resistance, anti-aging, large friction coefficient, uniform hole, convenient construction and long service life.

(4).It is more suitable for deep sea operation and embankment reinforcement, which fundamentally solves the technical problems of low strength, poor corrosion resistance and short service life caused by other materials used for stone cage erosion due to long-term seawater erosion.

(5).can effectively avoid the construction damage caused by the rolling and damage of the machine during the construction process.