- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ or customized

-

Power:

-

7.5KW

-

Dimension(L*W*H):

-

3mX1.9mX1.6m

-

Weight:

-

2500 kg

-

Name:

-

paper tube machine

-

Output paper:

-

paper core,paper tube

-

Finished Products:

-

toilet tissue paper tube

-

Application:

-

toilet tissue paper

-

Raw material:

-

craft paper roll

-

cutting paper core max thicknes:

-

15mm

-

Control system:

-

PLC+Touch Screen

-

Advantage:

-

Easy Operation Aoto Cutting

-

After-sales Service:

-

Professional Technical Guidance

-

Certification:

-

CE

Quick Details

-

Production Capacity:

-

Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TURUI

-

Voltage:

-

380V 50HZ or customized

-

Power:

-

7.5KW

-

Dimension(L*W*H):

-

3mX1.9mX1.6m

-

Weight:

-

2500 kg

-

Name:

-

paper tube machine

-

Output paper:

-

paper core,paper tube

-

Finished Products:

-

toilet tissue paper tube

-

Application:

-

toilet tissue paper

-

Raw material:

-

craft paper roll

-

cutting paper core max thicknes:

-

15mm

-

Control system:

-

PLC+Touch Screen

-

Advantage:

-

Easy Operation Aoto Cutting

-

After-sales Service:

-

Professional Technical Guidance

-

Certification:

-

CE

Product Description

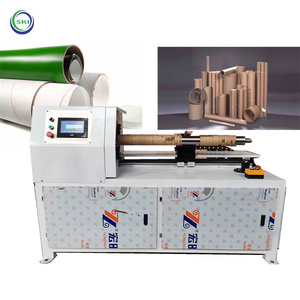

Automatic kraft toilet paper core cutter spiral cardboard paper tube core pipe cutter cutting making machine for sale

paper core tube making machine is mainly used for making paper tube. The tubes made can be used as core of toilet paper roll.We have different model of paper core machine for choice, can make paper tube with different diameter and thickness. The finished tube can be cut and discharged automatically. Infrared and automatic transmission make cutting length more accurate.

Equipment Parameter

Production process

Detail Images

Automatic kraft toilet paper core cutter spiral cardboard paper tube core pipe cutter cutting making machine for sale

1. Strong versatility and high-performance configuration.

2. Using PLC logic control system touch screen man-machine interface operation.

3. The main motor adopts vector-type high-torque frequency converter for speed regulation.

4. Length of photoelectric positioning meter+computer length control, precise cutting of length.

5. Modular electrical layout design makes it more convenient and scientific to use, maintain and repair.

6. It is more convenient to operate and use(for example, it can automatically stop when the paper breaks).

7. Low noise transmission design.

8. Adopting double-sided gluing independent stainless steel glue tank, the finished paper tube has good hardness.

9. Servo screw cuts synchronously, with even gaps, suitable for the production of paper tubes of various tapes, roll paper chemical fiber tubes, and packaging paper cans.

Packaging &Delivery

Packaging:

1. Fixed all the movable parts with plastic films.

2. Polystyrene foam plate wrapped around.

3. Wrapped with tighted plastic films several circles.

4. Fixed machine on the fumigated plywood pallet with iron wire.

5. Wrapped with wooden board around and nailed on.

Shipment:

1. Sea transportation is from Qingdao port or other ports.

2. The delivery time is decided by your needed machines or machine parts. But it also follows your needs.

After Sales:

1.Highly inspecting equipments in every working procedure, quality comes first;

2. Assisting our clients for foundation construction of equipments;

3. Dispatching engineers to install and debug equipments;

4.Training the first-line operators one site;

5. One year warranty, we provide free machine parts within one year.

FAQ

Q: How to choose a suitable machine?

A: Please tell us your requirements and what capacity you need; we will recommend you the most suitable one.

Q: Will you test the machine before delivery?

A: Yes, we will test every machine and production line before delivery and send you the working video. You also can come to us for inspection before delivery.

Q: Do you provide product design according to client’s demands?

A: Yes, we can design the machine according to your demands as a manufacture.

Q: What About installation?

A: For the shredder installation, we will provide you the wire connection drawing and technical support, normally you can finish by yourself; but if you really need our technician, we will send technician to your working site as required.

Q: How About the Spare Parts?

A: We provide spare parts at cost price permanently and will give you the spare parts list when you purchase machine.

Q: How long is your warranty?

A: Within 1 year from the date of installation, when there is the quality problem (except wearing parts), we provide these parts for free.

Hot Searches