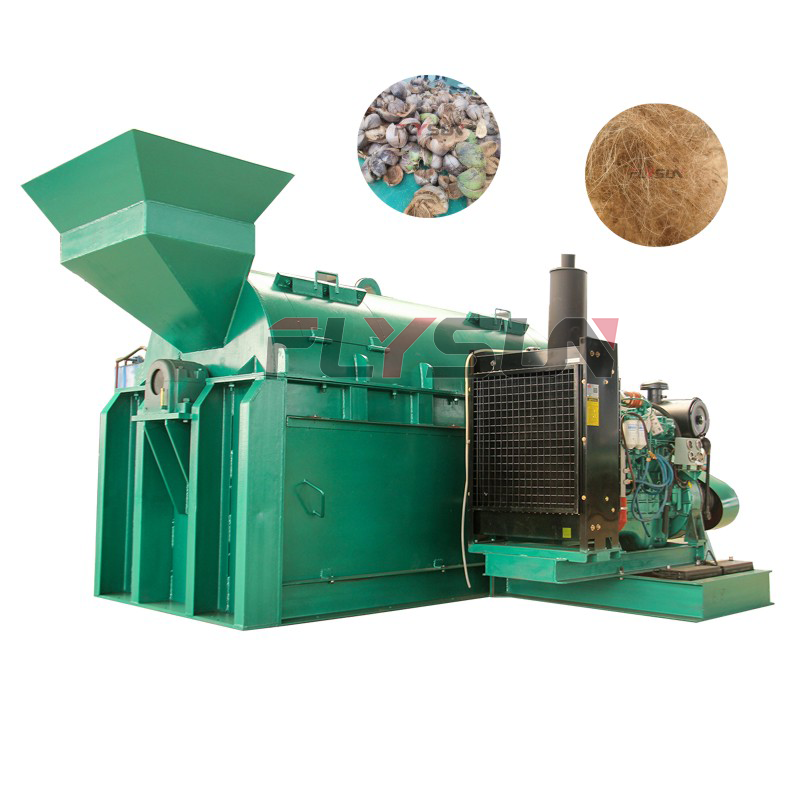

Coconut husk defibering machine can extract fiber and peat, Our company has developed and produced advanced coconut shell fiber

separators. Advantage

1.High degree of automation.

2.Simple structure.

3.Strong practicability.

4 Realized the large-scale production.

5.High capacity.

- Product Details

- {{item.text}}

Quick Details

-

Features:

-

Easy Operation High Efficiency

-

Production Capacity:

-

120-1800 kg/h

-

Dimension(L*W*H):

-

2700X2100X1900mm

-

Power:

-

110kw

-

Voltage:

-

380V(can customized)

-

Weight (KG):

-

3500

-

Video outgoing-inspection:

-

Provided

-

Machinery Test Report:

-

Provided

-

Marketing Type:

-

New Product 2023

-

Warranty of core components:

-

1 Year

-

Name:

-

Coconut Fiber Extracting

-

Usage:

-

Agricultural Machinery Farm Machinery

-

Keywords:

-

Coconut Fiber Processing Machine

-

Color:

-

Customized Color

-

After-sales Service Provided:

-

On-site Installation

-

Advantage:

-

High Performance Labor Saving

-

Raw material:

-

cocount shell

-

Type:

-

Farm Equipment

-

Raw material application:

-

cocount shell

-

Certificate:

-

CE ISO9001

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Flysun

-

Application:

-

Separate coconut fiber silk and coconut bran

-

Features:

-

Easy Operation High Efficiency

-

Production Capacity:

-

120-1800 kg/h

-

Dimension(L*W*H):

-

2700X2100X1900mm

-

Power:

-

110kw

-

Voltage:

-

380V(can customized)

-

Weight (KG):

-

3500

-

Video outgoing-inspection:

-

Provided

-

Machinery Test Report:

-

Provided

-

Marketing Type:

-

New Product 2023

-

Warranty of core components:

-

1 Year

-

Name:

-

Coconut Fiber Extracting

-

Usage:

-

Agricultural Machinery Farm Machinery

-

Keywords:

-

Coconut Fiber Processing Machine

-

Color:

-

Customized Color

-

After-sales Service Provided:

-

On-site Installation

-

Advantage:

-

High Performance Labor Saving

-

Raw material:

-

cocount shell

-

Type:

-

Farm Equipment

-

Raw material application:

-

cocount shell

-

Certificate:

-

CE ISO9001

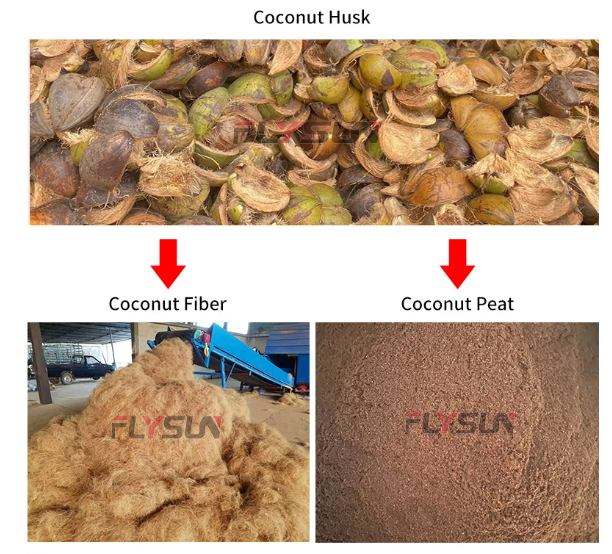

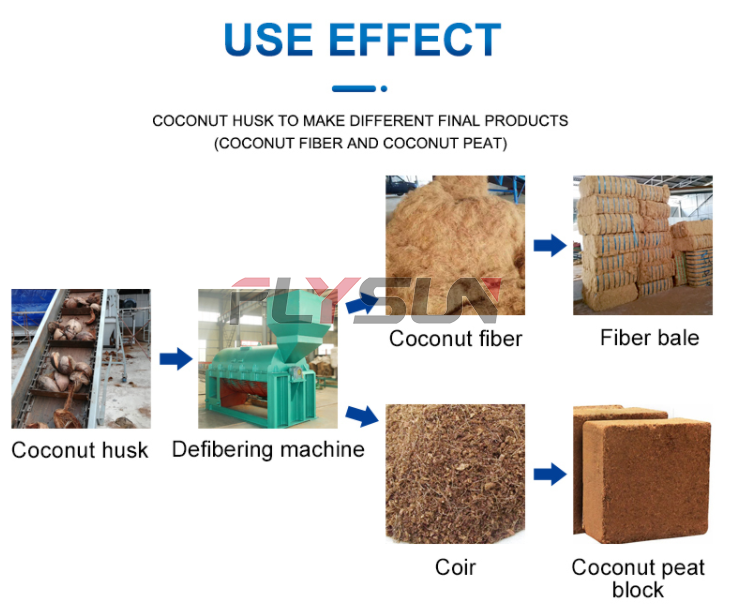

Products Description

Defibering Machine

Defibering machine is also called coconut skin grater, palm crusher, coconut shell silk making machine, etc., is a kind of coconut shell, palm shell, bamboo, sugar cane and other materials after crushing, processing into fiber filaments, is a professional fiber extraction equipment.

The machine is composed of a frame, top cover, rotary cutter, wire cutter, motor, electric control cabinet, etc. The rotary cutter is mounted on the frame of the wire cutter through the bearing, the motor drives the rotary cutter through the triangle belt to rotate at high speed, and the electrical box and starting electrical apparatus control the machine.

Product A

dvantages:

1. Stable Structures, Running Safety.

2. Output Coco fiber size could be adjustable based on requirements.

3. Coconut Coir Machine Fully Automatic running, Easy operate and maintain.

4. Engineer will go to customer working site installation guidance.

Working Principle

The raw material is put into the machine from the feed port by conveyer or manual, and the machine is driven by the triangle belt to rotate the wire cutter and beat the coconut peel into the machine, so that the coconut silk and coconut bran are separated to crush and open the material, and the impurity part is separated through the screen, while the fibrous palm silk is directly discharged from the discharge port. At the same time, it can be connected with the conveyor system of the next process for further screening, drying, compression packaging or crushing and other deep processing. The bran falls through the hole under the fuselage.

Technical Parameters

Single Drum Shredded Coconut fiber extracting machine

|

Model

|

Power

|

Capacity(kg/h)

|

Weight(kg)

|

Dimension(mm)

|

|

JPD-I

|

37

|

300

|

1800

|

1800×1200×1600

|

|

JPD-II

|

45

|

400

|

2100

|

2000×1500×1600

|

|

JPD-III

|

55

|

500

|

2500

|

2200×1700×1700

|

|

JPD-XI

|

75

|

600~700

|

3100

|

2500×2000×1900

|

|

JPD-XII

|

110

|

800~900

|

3500

|

2700×2100×1900

|

|

JPD-XY

|

110

|

1200~1500

|

4200

|

3100×2200×2000

|

Double Drum Shredded Coconut fiber extracting machine

|

Model

|

Power(kw)

|

Capacity(kg/h)

|

Weight(kg)

|

Dimension(mm)

|

|

JZD-I

|

37+55

|

500

|

3400

|

3410×2300×1720

|

|

JZD-II

|

55+75

|

600-700

|

4100

|

4800×2250×1800

|

|

JZD-III

|

75+95

|

900-1000

|

4800

|

5750×2400×1900

|

|

JZD-XI

|

95+110

|

1500-1800

|

5100

|

6100×2600×2100

|

Coconut husk defibering machine

Coco coir screening machine

Coco coir screening machine also called coconut fiber and peat separation equipment. it can be used for screening some different

raw material, such as coconut, etc.Our Coco Coir screeing machine has a wide range of applications, not only for screening coco

coir.

Advantage

1.Easy to operate and low noise,

2.Automatic screening,

5.High capacity

6.The screening hole size can be customized.

raw material, such as coconut, etc.Our Coco Coir screeing machine has a wide range of applications, not only for screening coco

coir.

Advantage

1.Easy to operate and low noise,

2.Automatic screening,

5.High capacity

6.The screening hole size can be customized.

Coconut fiber baller machine.

Coconut fiber baller machine can be used for packing loose materials such as shredder coconut,coconut peat and fiber, straw etc

Our hydraulic coconut fiber baller machine has a wide range of applications, not only for packaging coconut fiber. Advantage

1.Easy to move and install,

2.Easy to operate, low noise,

3.High pressure, fast compaction.

4.Automatic bag pushing and turning design

5.High capacity

6.The baling length can be set at random,.

Our hydraulic coconut fiber baller machine has a wide range of applications, not only for packaging coconut fiber. Advantage

1.Easy to move and install,

2.Easy to operate, low noise,

3.High pressure, fast compaction.

4.Automatic bag pushing and turning design

5.High capacity

6.The baling length can be set at random,.

Coconut peat belt filter machine

Coconut Peat belt filter machine

Our coconut peat belt filter machine manufacturing technology is mature, and the equipment can operate for a long time. Advantage

1. Simple design and efficient work,

2. Automatic control, stable operation,

3. Few faults, low noise and vibration.

Our coconut peat belt filter machine manufacturing technology is mature, and the equipment can operate for a long time. Advantage

1. Simple design and efficient work,

2. Automatic control, stable operation,

3. Few faults, low noise and vibration.

Coconut peat press block machine

Our coconut peat press block machine is hydraulically driven to quickly press coconut bran peat into solid bricks.

Advantage

1.High configuration,

2. Good quality,

3. Stable operation

Advantage

1.High configuration,

2. Good quality,

3. Stable operation

Coconut husk processing production line

Our coconut husk processing line processes waste coconut shells into valuable coconut fiber silk and coconut bran peat. Coconut fiber silk is used to make mattresses and

brooms

, and coconut bran peat is used to cultivate vegetables, flowers. This line not only solves environmental pollution but also achieved waste reuse. It is a good choice for investors.

Customer Case

Philippines customer coconut husk processing line

In 2017, we designed and installed a coconut husk processing line with a daily output of 8 tons for Philippines customers.the picture is coconut fiber extracting machine which is part of the whole processing line.

Malaysia customer coconut husk processing line site

In 2019, we designed and installed a 12 tons per day coconut husk processing line for a Malaysia customer. Pictured is a coconut fiber packaging machine, which is part of the entire producessing line.

Packaging and shipping

Hot Searches