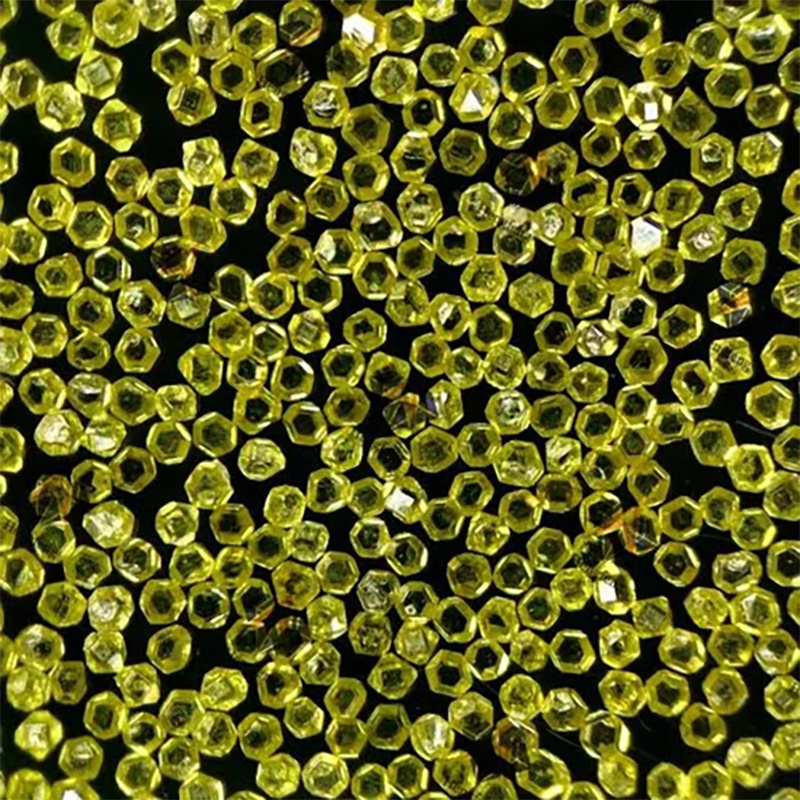

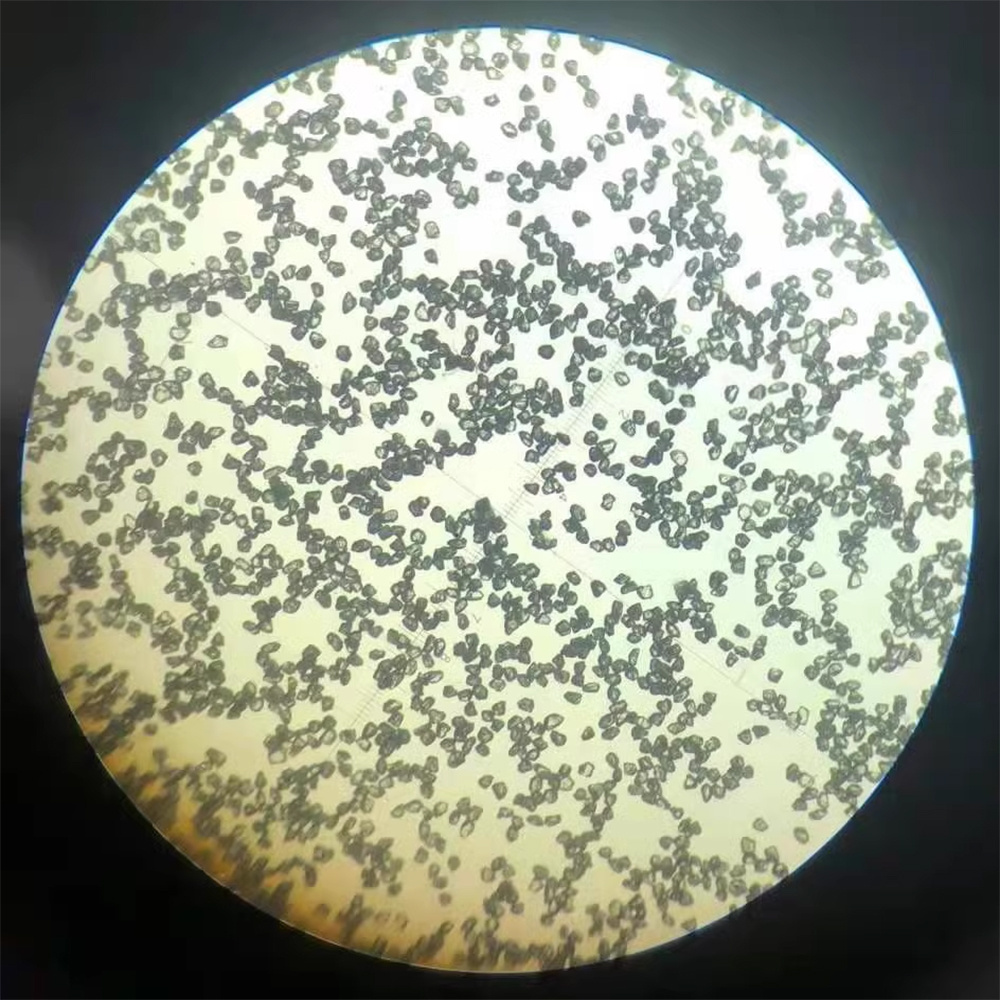

Diamond powder, also known as diamond dust or diamond grit, is a fine abrasive substance composed of small, synthetic, or natural diamond particles. This powder is widely used in various industrial applications and processes due to the exceptional hardness of diamonds.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

XINLI

-

Model Number:

-

Diamond Powder

-

Use:

-

grinding.polishing, lightening, colorant

-

Color:

-

light yellow, grey, green

-

Usage:

-

Resin bonded abrasive tools for grinding and polishing carbide, glass.

-

High temperatur:

-

700-800℃

-

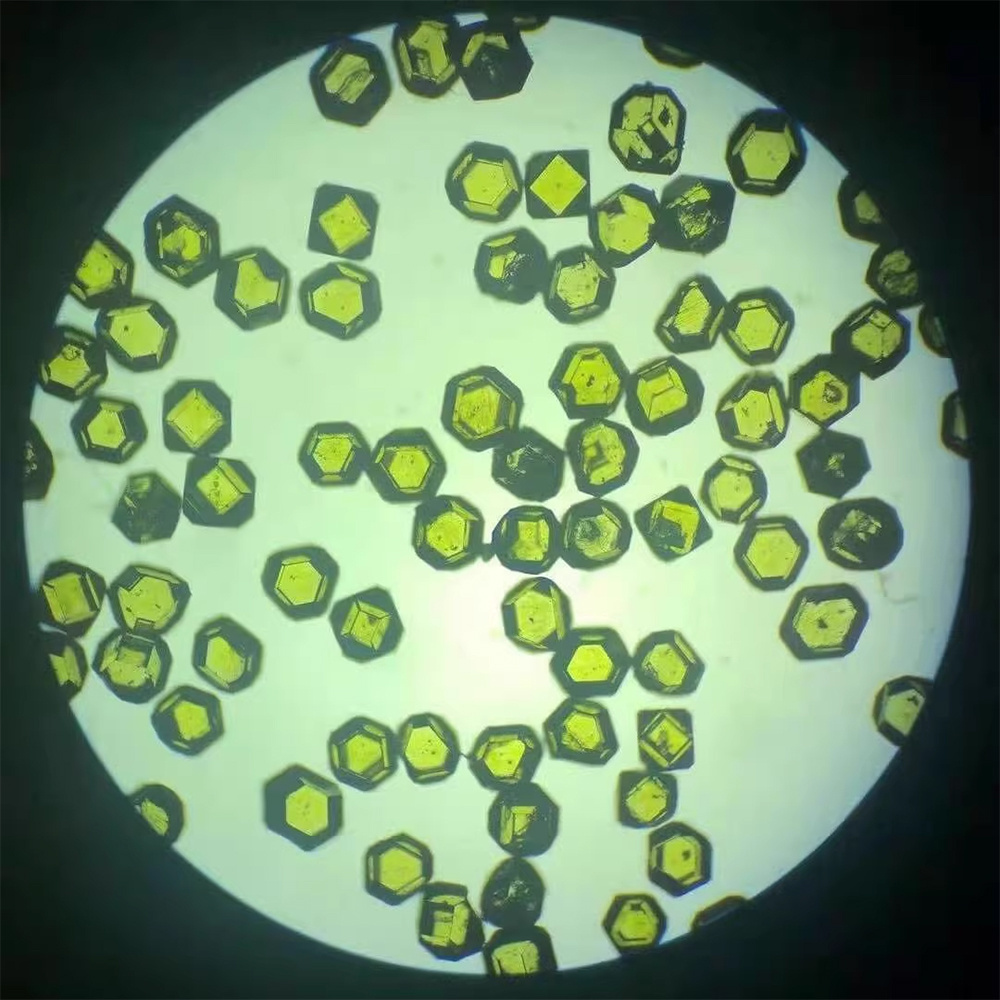

Shape:

-

Regular

-

Sample:

-

Available

-

Package:

-

Plastic Bag or Bottle

-

Feature:

-

High Efficiency

-

Product Name:

-

synthetic diamond powder

-

Certification:

-

ISO9001

Quick Details

-

Type:

-

Cutting, drilling, grinding

-

Abrasive Grain Sizes:

-

50#-500#, Requirement

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XINLI

-

Model Number:

-

Diamond Powder

-

Use:

-

grinding.polishing, lightening, colorant

-

Color:

-

light yellow, grey, green

-

Usage:

-

Resin bonded abrasive tools for grinding and polishing carbide, glass.

-

High temperatur:

-

700-800℃

-

Shape:

-

Regular

-

Sample:

-

Available

-

Package:

-

Plastic Bag or Bottle

-

Feature:

-

High Efficiency

-

Product Name:

-

synthetic diamond powder

-

Certification:

-

ISO9001

Product Description

Diamond Powder/Dust

Features and Advantages

Diamond can be used for mirror polishing of wire drawing dies, and can also be used for mirror polishing of crystals and silicon wafers. It has excellent wear resistance, corrosion resistance, and thermal conductivity; it has high purity, smooth polishing effect, and the main impurity content is less than 1ppm; the surface Roughness is less than 0.8nm.

|

Diamond Powder Specification

|

|

|

|

Model

|

Applicable scope

|

|

|

W0.25

|

Super mirror polishing and grinding

|

|

|

W0.5

|

Super mirror polishing and grinding

|

|

|

W1.0

|

Mirror polishing and grinding

|

|

|

W1.5

|

Mirror polishing and grinding

|

|

|

W2.5

|

Fine polishing and grinding

|

|

|

W3.5

|

Fine polishing and grinding

|

|

|

W5.0

|

Fine polishing and grinding

|

|

|

W7.0

|

Fine polishing and grinding

|

|

|

W10

|

Ordinary polishing and grinding

|

|

|

W14

|

Ordinary polishing and grinding

|

|

|

W20

|

Ordinary polishing and grinding

|

|

|

W28

|

Ordinary polishing and grinding

|

|

|

W40

|

Rough grinding, polishing and grinding

|

|

|

W50

|

Rough grinding, polishing and grinding

|

|

|

W60

|

Rough grinding, polishing and grinding

|

|

Applications

Nanodiamond powder is widely used in aerospace, aircraft manufacturing, precision machinery, optical instruments, automobile manufacturing and other industries;

1. A powerful polish that achieves an atomically polished surface. Used for the finishing and polishing of various hard material products such as fine ceramics, integrated circuit chips, various gemstones, ferrite heads, quartz chips, superhard alloys, optical lenses, etc.;

2. High hardness and high wear resistance electroplating and non-electroplating layers;

3. High hardness and high wear-resistant metal composite materials;

4. Low friction, low wear, high load, long life lubrication system (such as lubrication of various cylinders) and super

lubricating oil.

5. PTFE-based composite material with high wear resistance and good lubricity;

6. It is a good material for producing polycrystalline diamond and diamond films.

7. It is the main material for producing nanodiamond thermal penetration.

2. High hardness and high wear resistance electroplating and non-electroplating layers;

3. High hardness and high wear-resistant metal composite materials;

4. Low friction, low wear, high load, long life lubrication system (such as lubrication of various cylinders) and super

lubricating oil.

5. PTFE-based composite material with high wear resistance and good lubricity;

6. It is a good material for producing polycrystalline diamond and diamond films.

7. It is the main material for producing nanodiamond thermal penetration.

Hot Searches