- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Nylon Rod

-

Density (g/cm3):

-

1.4

-

Friction coefficient:

-

0.6

-

Temperature (continuous):

-

55

-

Rockwell hardness:

-

82

-

Soft temperature:

-

120

-

Anti-electric Strength(KV/mm):

-

20-40

-

Glass transition temperature:

-

87

-

Volume Resistance(Ω.cm):

-

≥1015

-

Linear thermal expansion coefficient:

-

80X10-6

-

Surface Resistivity:

-

≥1013

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Fangdun

-

Model Number:

-

Nylon Rod

-

Density (g/cm3):

-

1.4

-

Friction coefficient:

-

0.6

-

Temperature (continuous):

-

55

-

Rockwell hardness:

-

82

-

Soft temperature:

-

120

-

Anti-electric Strength(KV/mm):

-

20-40

-

Glass transition temperature:

-

87

-

Volume Resistance(Ω.cm):

-

≥1015

-

Linear thermal expansion coefficient:

-

80X10-6

-

Surface Resistivity:

-

≥1013

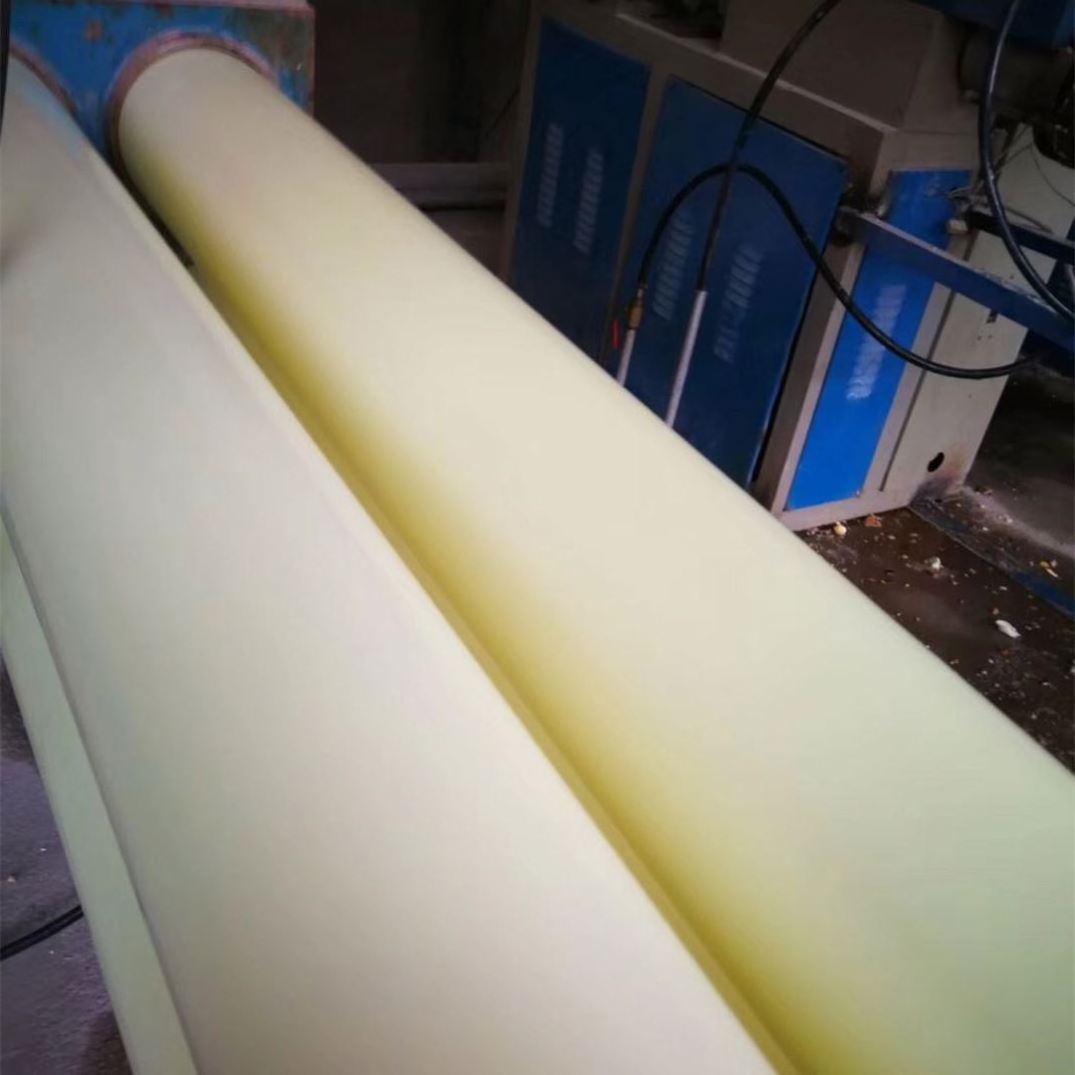

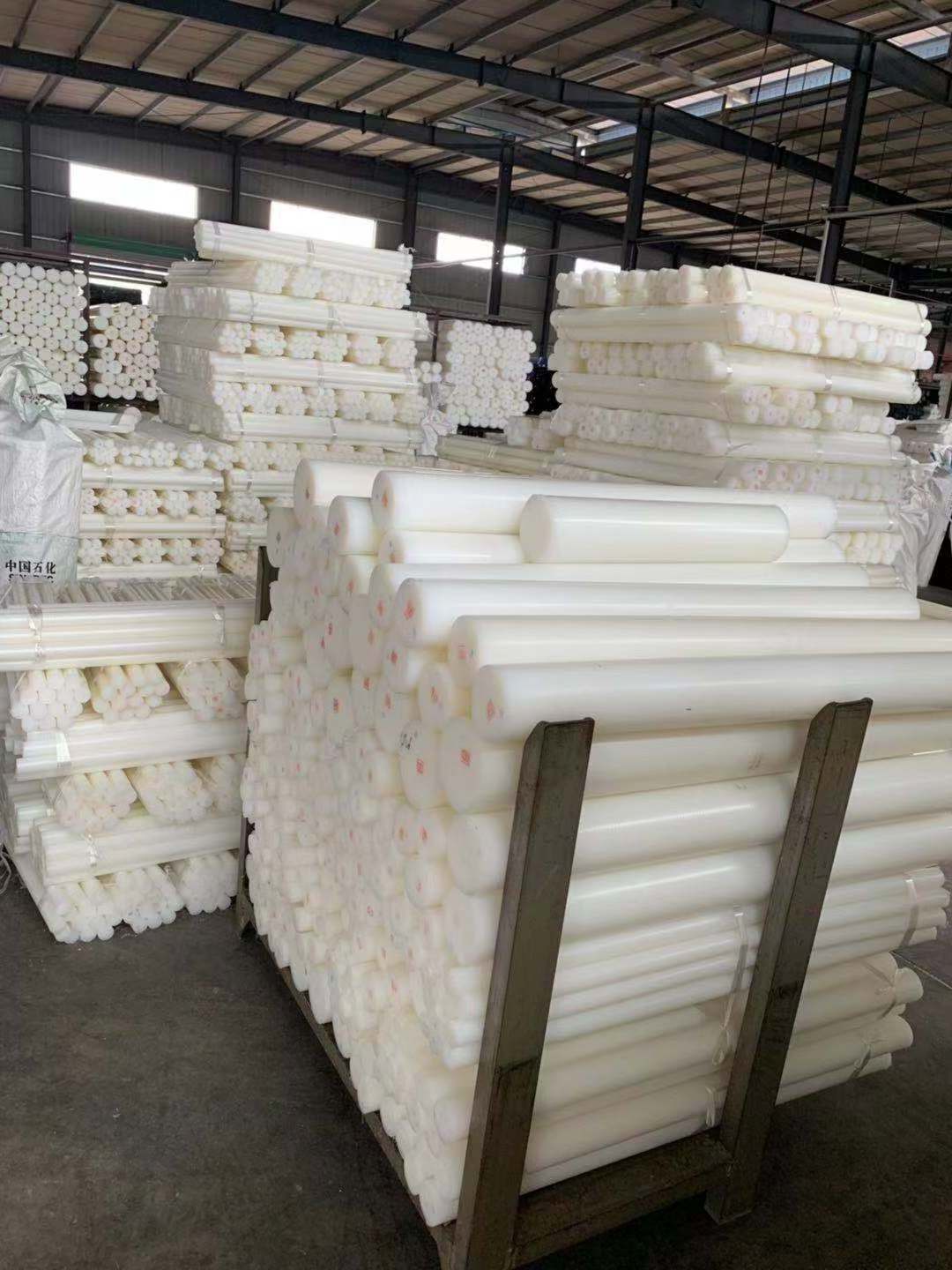

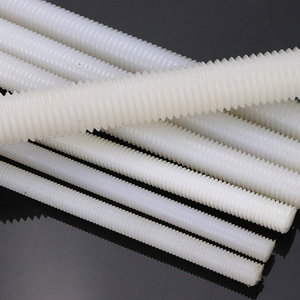

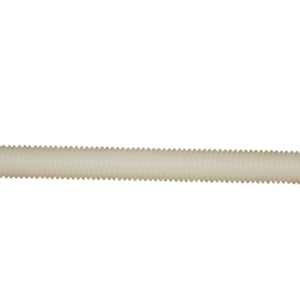

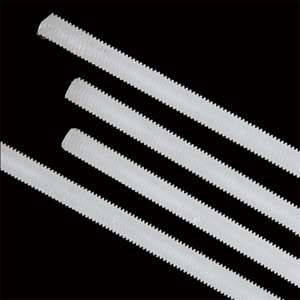

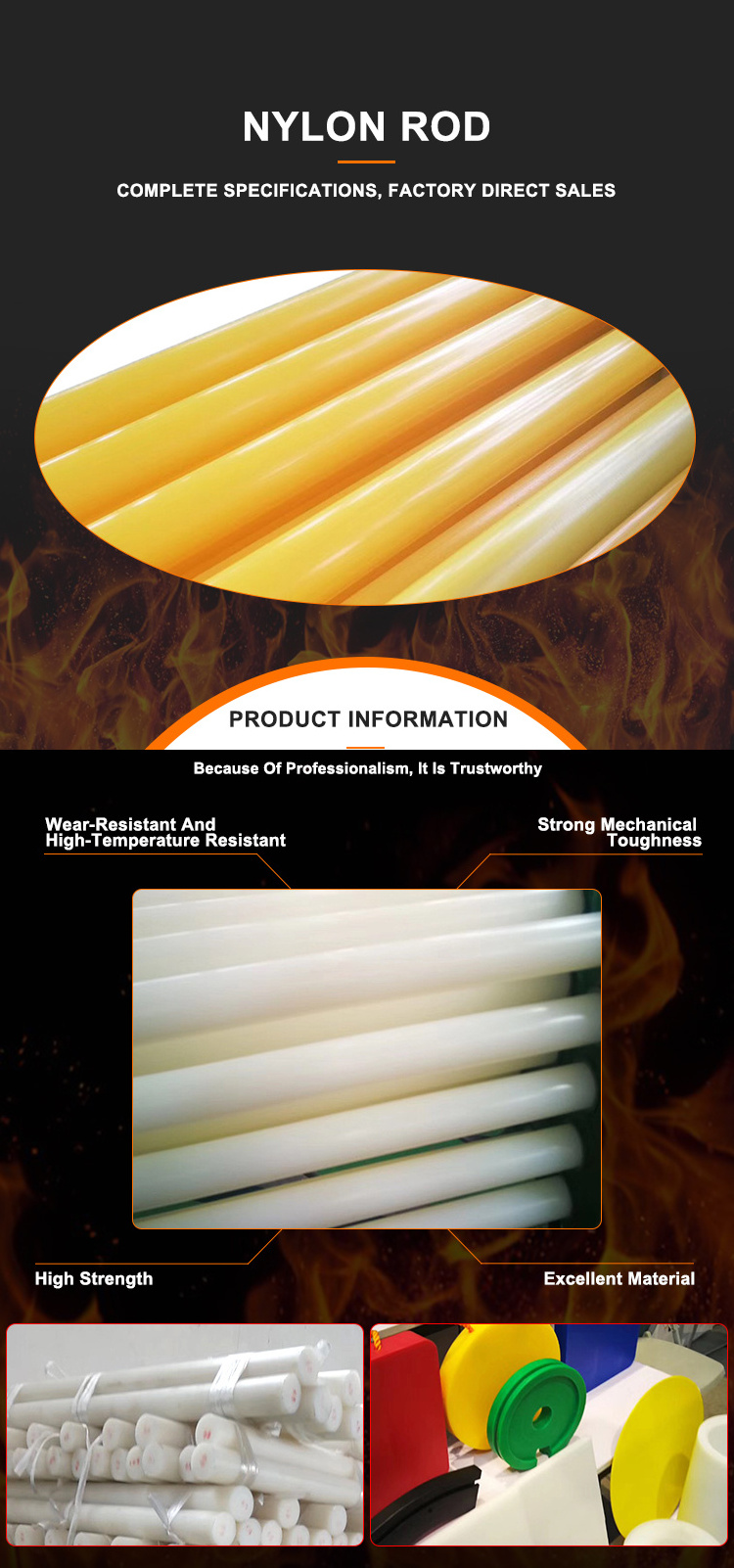

Customized Size Bearing Threaded Nylon Plastic Rod

Description of natural nylon rod

Specifications:

(Thickness)6mm-100mm,(length and width) 1000*1200mm, 1200*2600mm, 1100*3100mm

(Thickness)10mm-200mm,(length and width)1000*1000mm,600*1200mm

Other sizes can be customized.

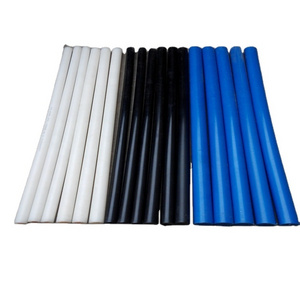

Color:

Natural color, yellow, blue, black, green.

Grade:

A (Density 1.18-1.2 g/cm 3 )

B (Density 1.2-1.25 g/cm 3 )

C (Density 1.3-1.5 g/cm 3 )

MC Nylon sheet (PA6) also named Monomer Casting Nylon is a engineering plastic sheet which is widely

usded in all industrial area. It’s light, high strength, wear-resisting, insulating and so on. So it is mainly

used as gears and parts, chemical machinery, electric parts, automobile parts, chemical equipment, etc.

Applications of natural nylon rod

1) Used in the mechanical performance requirements of a high motor, electrical equipment and

insulating structural parts.

2) ICT, ITE rule the processing of the insulation parts, test fixtures, silicon rubber keypads mold.

3) Fixture plate, mold plywood, countertops grinding plate, packaging machines, comb, etc.

Technical of natural nylon rod

Density (g/cm3) 1.4 Friction coefficient 0.6

Temperature (continuous) 55 Rockwell hardness 82

Soft temperature 120 Anti-electric Strength(KV/mm) 20-40

Glass transition temperature 87 Volume Resistance(Ω.cm) ≥1015

Linear thermal expansion coefficient 80X10-6 Surface Resistivity ≥1013

Flammability V-O Tensile modulus of elasticity(Mpa) 3000

| Density (g/cm3) | 1.4 | Friction coefficient | 0.6 |

| Temperature (continuous) | 55 | Rockwell hardness | 82 |

| Soft temperature | 120 | Anti-electric Strength(KV/mm) | 20-40 |

| Glass transition temperature | 87 | Volume Resistance(Ω.cm) | ≥1015 |

| Linear thermal expansion coefficient | 80X10-6 | Surface Resistivity | ≥1013 |

| Flammability | V-O | Tensile modulus of elasticity(Mpa) | 3000 |