SHUOXIN TF-600 model Fertilizer Spreaders are produced with Single discs, 600 Kgs capacities and 8-12meters working width.

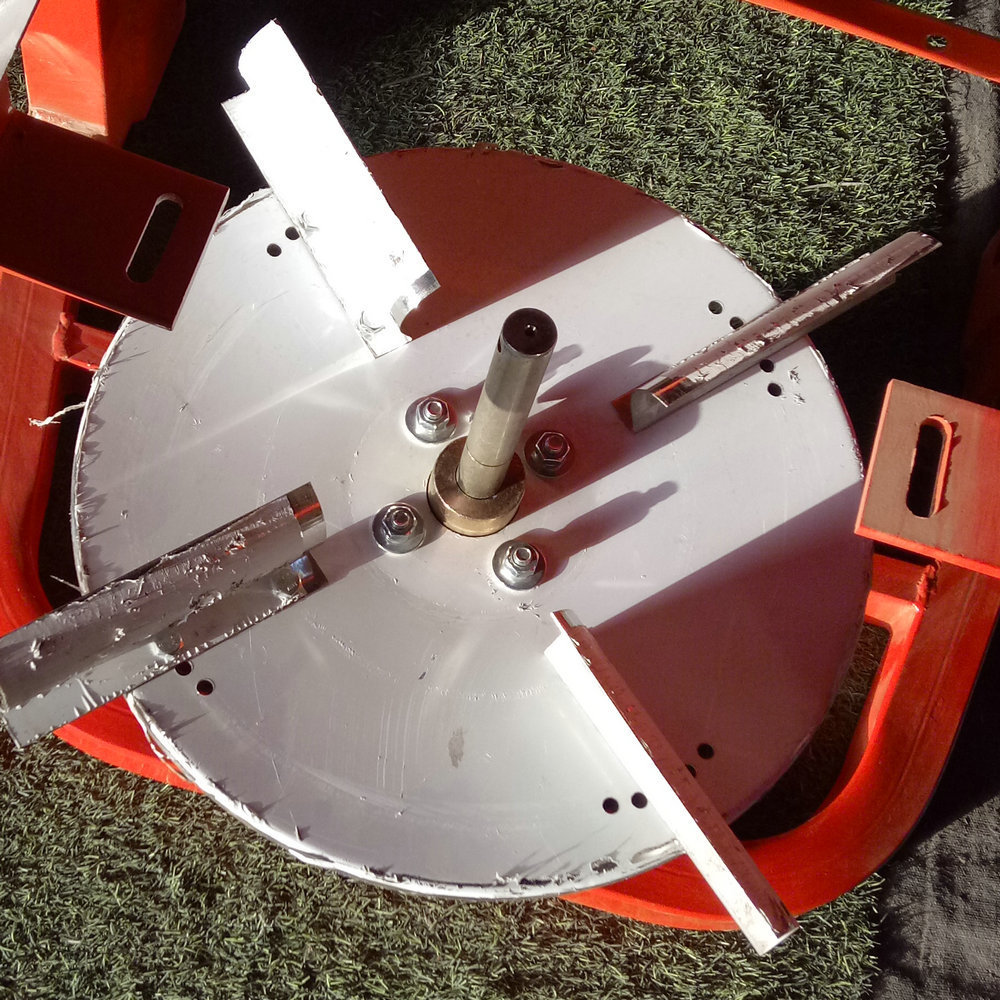

These mounted type fertilizer spreaders are mounted to tractor's universal three point linkage system and hydraulic top link. Spreading discs made from stainless steel material. Horizontal mixer provides falling of fertilizer onto spreading discs easily. Fertilizer spreading degree can be easily adjusted by means of hydraulic lift.

When fertilizing the agricultural fields surrounding, the limiter mounted on the machine enables the prevention of fertilizing out of the field. The limiter prevents the mineral fertilizer to harm the environment and enables the most efficient use of the fertilizer. The limiter can be mounted on the right of left side of the machine. It would be sufficient to use the limiter on just one side.