- Product Details

- {{item.text}}

Quick Details

-

Power:

-

0-10kw

-

Dimension(L*W*H):

-

various in different tank

-

Weight:

-

1000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Commodity:

-

beer equipment

-

Material:

-

SUS304

-

Fermenter cone:

-

60/72

-

Manhole:

-

top /side

-

Thickness:

-

2-4mm / Inside:3.0mm

-

Heating mothed:

-

Steam

-

Inner surface treatment:

-

Interior polish Ra0.4

-

name:

-

fermentation equipment

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

METO

-

Voltage:

-

380v/3phrase /50hz

-

Power:

-

0-10kw

-

Dimension(L*W*H):

-

various in different tank

-

Weight:

-

1000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Commodity:

-

beer equipment

-

Material:

-

SUS304

-

Fermenter cone:

-

60/72

-

Manhole:

-

top /side

-

Thickness:

-

2-4mm / Inside:3.0mm

-

Heating mothed:

-

Steam

-

Inner surface treatment:

-

Interior polish Ra0.4

-

name:

-

fermentation equipment

-

Certification:

-

CE ISO

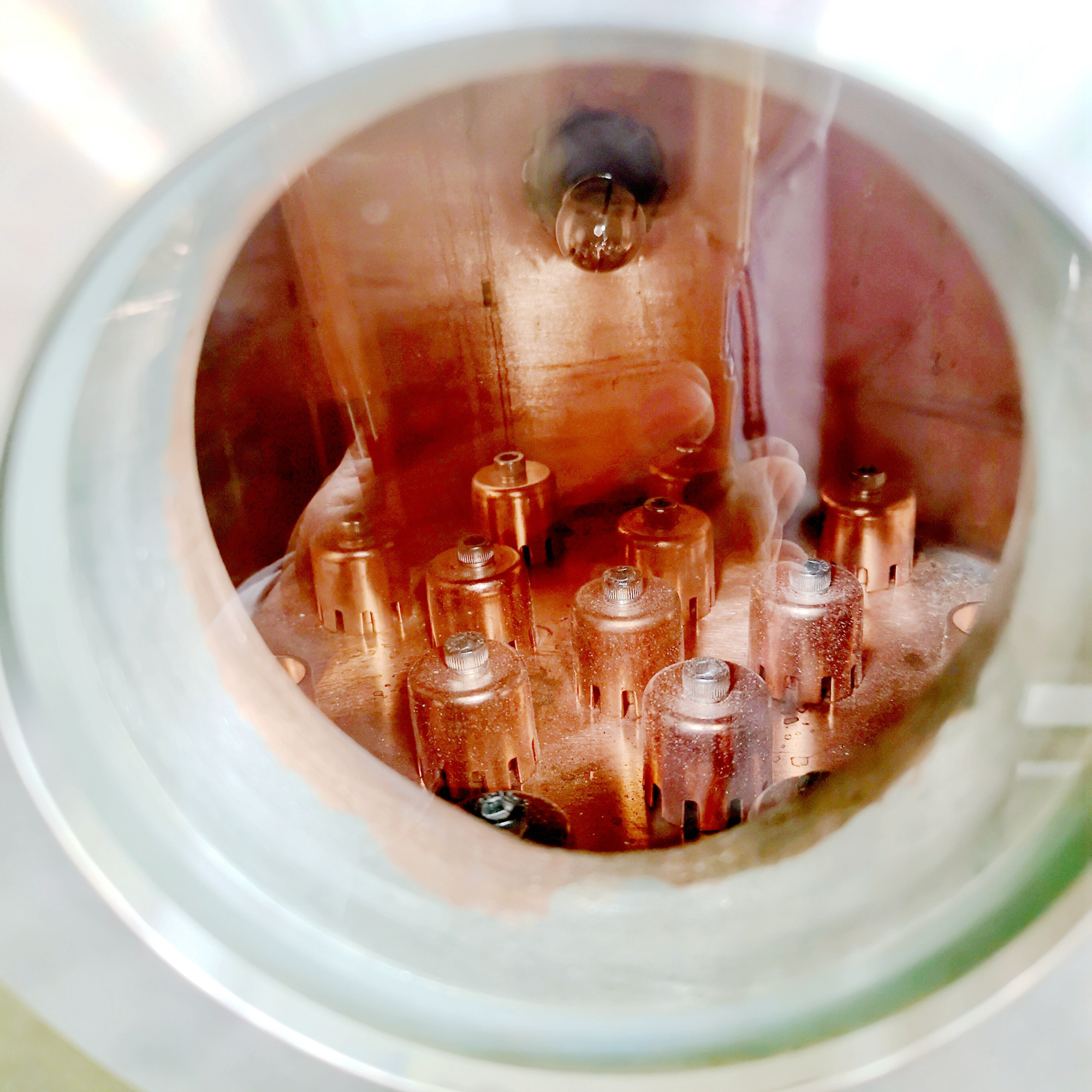

METO alcohol distiller boiler copper pot still distillation machine whiskey distillery equipment for sale

Main Technical Parameter of METO FERMENTER:

| Descriptions | Parameters |

| Model | MTFV-300L |

| Test Pressure | 3 Bar |

| Useful Pressure | 1.5 Bar |

| Material | sus 304 |

| Interior shell thickness | 3mm |

| Exterior shell thickness | 2mm |

| Conical Degree | 60° or 72 ° |

| Surface Roughness of Inner Shell | ≤Ra0.4µm |

| Head Type | Butterfly head |

| Cooling Jacket Type | Dimple plate jacket |

| Insulation Material | Polyurethane insulation 80mm |

| Top Manhole | Pressure manhole |

| Beer outlet | φ32 - φ51 |

| Ice Water inlet/outlet | G3/4 -G1 |

| Temperature Display | PT100 |

METO Advantages:

--METO Beer Equipment certificated by ISO TUV SGS production process inspection, the tanks ’ design and quality can be according to GB/CE/PED/ASME standard.

--Local service in EUROPE, AUSTRALIA etc.

-- 5 Years warranty for tanks.

--0 trade risk verified by more than 30 00 breweries.

--20 Years experience design customization.

--Electrical parts CSA/UL certificated available.

METO Fermentation tank:

Cylindroconical fermenters are the most commonly used fermentation systems used today to produce both lagers and ales. As the name implies, the vessels are vertical cylinders with a conical base (usually 60°cone) and normally, a dished top . This design allows for easy yeast collection and CIP cleaning. Beer Brewing Equipment Fermentation Tank 5000l 6000l Commercial Beer Brewing Equipment Brewery Turnkey Project

Beer Brewing Equipment Fermentation Tank 5000l Commercial Beer Brewing Equipment Brewery Turnkey Project are very suitable for micro breweries and brewpubs, bars etc. It ’ s self-cooled with glycol water inlet and outlet, so the temperature of beer during fermentation can be controlled easily. In addition, each beer fermentation tank is equipped with 360°rotated CIP spraying ball. the tank inner could be cleaned completely. This can ensure the food-grade sanitary of beer production.

The 1000L fermenter is usually installed with 500L and 1000L beer brewery equipment.

Based on different beer types requirements on output and fermentation cycle, usually 4-20 sets beer fermentation tanks are needed by most of the customers.

Standard Features:

Material: 304 stainless steel

Interior and exterior finish polished to a sanitary finish

Interior finish pickled and passivated

Exterior brushed, Fully welded exterior shell

60-72 degree cone bottom, with an average of 25% head space

Rotating racking port

Top manhole or side manhole

Dual zone dimple cooling jackets

Polyurethane insulation 80mm

CO2 blow off arm

CIP arm and spray ball

Sanitary tri-clamp connection

Dry hop port

Stainless steel handle butterfly valve,sample vale

Safety valve(Breathing valve),Water seal co2 exhaust valvee

Clamps and gaskets, pressure gauge

Stainless steel legs with stainless leveling footpads