- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

GT

-

Voltage:

-

220V,380V

-

Power:

-

5.5 Kw/ Set

-

Dimension(L*W*H):

-

1530*1181*1300MM

-

Weight:

-

1520 KG

-

Name:

-

bobbin winder machine/yarn winder machine

-

After-sales Service Provided:

-

YES

-

Keyword:

-

yarn winder machine

-

Speed:

-

900M/MIN

-

Color:

-

Green

-

MOQ:

-

1 Set

-

Package:

-

Container

-

Certification:

-

ISO

-

Kw:

-

5.5

-

SIZE:

-

1530*1181*1300MM

Quick Details

-

Marketing Type:

-

New Product

-

Application:

-

Winding

-

Production Capacity:

-

300-1000meters/min

-

Place of Origin:

-

China

-

Brand Name:

-

GT

-

Voltage:

-

220V,380V

-

Power:

-

5.5 Kw/ Set

-

Dimension(L*W*H):

-

1530*1181*1300MM

-

Weight:

-

1520 KG

-

Name:

-

bobbin winder machine/yarn winder machine

-

After-sales Service Provided:

-

YES

-

Keyword:

-

yarn winder machine

-

Speed:

-

900M/MIN

-

Color:

-

Green

-

MOQ:

-

1 Set

-

Package:

-

Container

-

Certification:

-

ISO

-

Kw:

-

5.5

-

SIZE:

-

1530*1181*1300MM

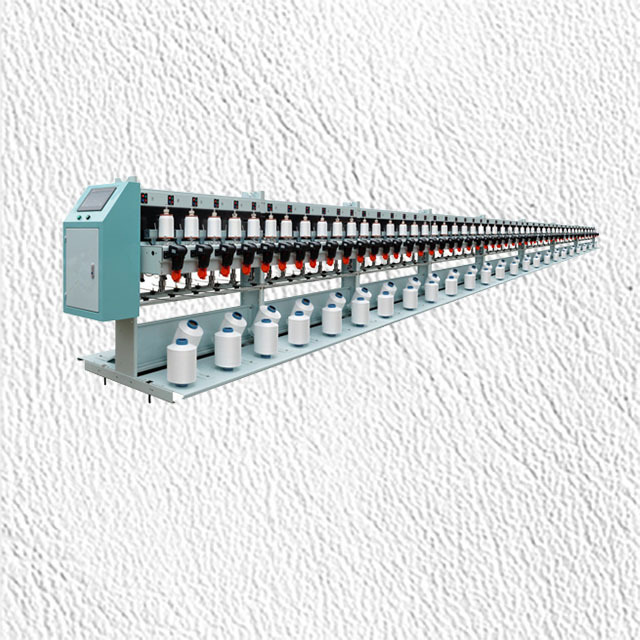

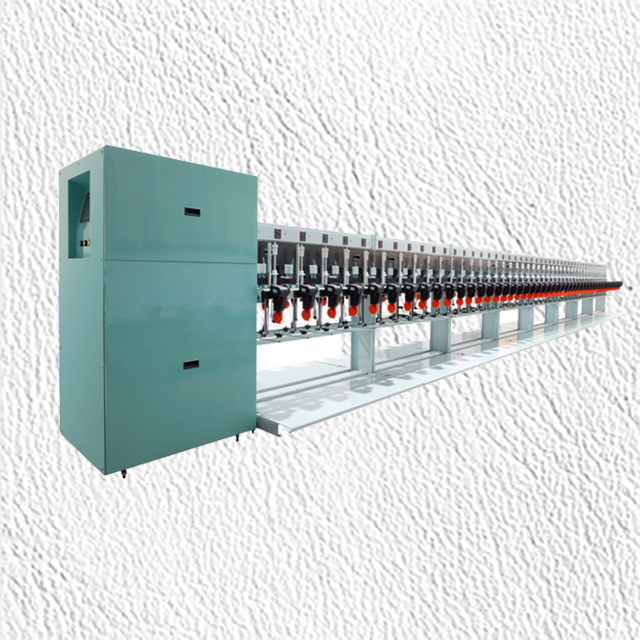

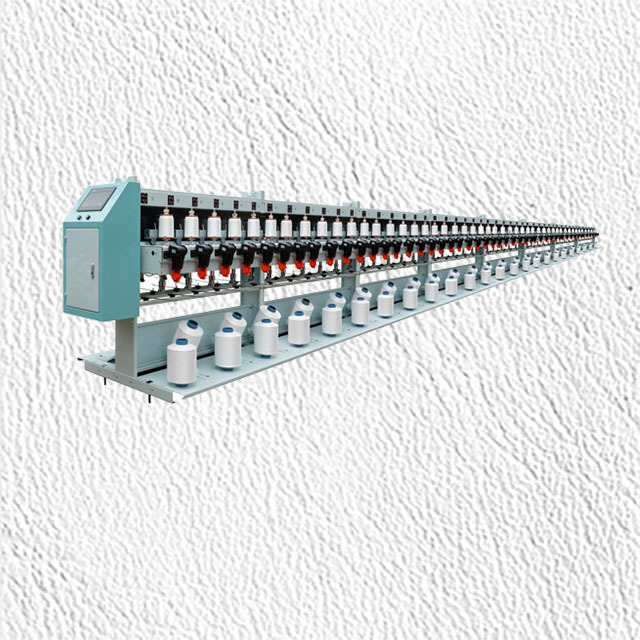

bobbin winder machine/yarn winder machine

It is suitable for parallel winding of common bobbin with the same diameter and single coning winding of different bobbin with high precision damping tensioner, and the tension value is stable and easy to adjust. Third, the use of new digital fixed length instrument, fixed length accuracy is high, tension fluctuation is stable, easy to adjust. The use of new spindle: fixed spindle base, to ensure that there will be no travel deviation due to long-term use of the bobbin friction damage, no operator inspection. The ingot spacing is large, which is conducive to the large roll yarn tube on the machine. The volume of the simple tube is increased by 50%-100% compared with the same period last year, which significantly reduces the labor of the whole process and realizes the production of large-roll non-jointing yarn. New spindle and single spindle motor, special structure design, running speed up to 1200 m/min, while using a simple structure design, reduce maintenance costs.

The pictures of our bobbin winder machine/yarn winder machine

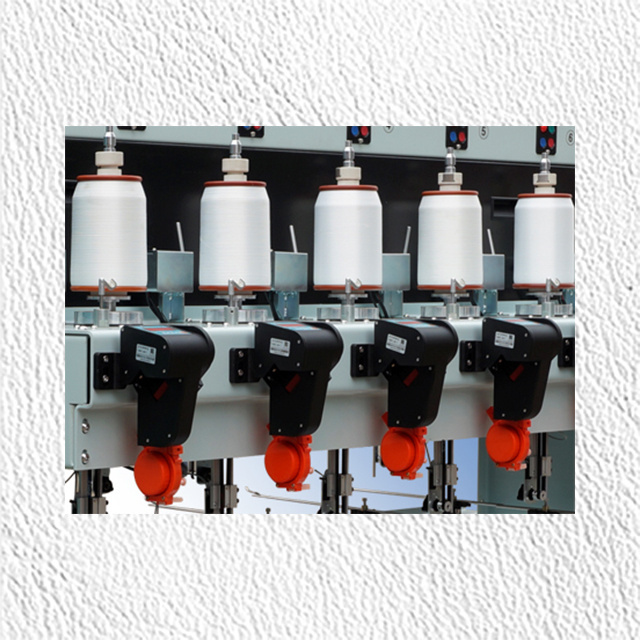

The details of our yarn winding machine

The technical data of our yarn winding machine

The features of our yarn winding machine

| 1. Applicable to parallel winding of common bobbins with the same diameter andsingle-sided awl-shaped winding of bobbins with different diameters. |

| 2. The high-precision damping tensioner is used,with stable tension value,whichis convenient to adjust. Suitable for more than 15D yarn. |

| 3. The new digital length apparatus is used,with high precision and stable tension,which is convenient to adjust. |

| 4. New spindles with fixed spindle seat, so as to ensure no deviation of strokecaused by the abrasion due to long-term use of the bobbin, and no operatorinspection is required |

|

5. Large spindle gauge is conducive to placing large packages of yarns on the

machine. |

| 6. The take-up volume capacity is increased by 50%-100%,which can obviouslyreduce the labor in the complete process, thereby realizing the production ofthe large-package jointless yarn. |

| 7. The new spindles and single spindle motor are used,with special structure andrunning speed up to 1200 m/min, and the simplified structure is adopted, thusreducing the later maintenance cost. The reduction of the bobbin unwindingside coil is beneficial to the unwinding of filaments or yarns,thereby reducingthe number of bobbin configurations of different sizes. The large spindle gauigeis beneficial to the winding operation of large-package yarn, and the large-capacity single-sided cone can be easily realized, with stable unwindingtension in the later stage and good consistency of basis weight. |

| 8. Equipped with the functions of automatic edge finding and half-bobbin yarnsplicing at any time,the machine can reduce labor and improve productionconvenience. |

| 9. Various shift production data and real-time monitoring of single spindle areprovided,thus facilitating the production management and subsequentdigitization and informatization of the factory. |

About our company

Certificates

If you have any question about yarn winding machine, welcome to contact me.