- Product Details

- {{item.text}}

Quick Details

-

Power:

-

7.5kw

-

Color:

-

yellow

-

Raw material:

-

wheat maize, corn, paddy, rice, sesame, soybean, sorghum

-

Total power:

-

6.5kw

-

Dimension:

-

4228*2750*9871mm

-

Drying time:

-

16h

-

Filled with grain time:

-

1h

-

Heat Source:

-

biomass hot blast stove,diesel stove, natural gas,electric burner

Quick Details

-

Place of Origin:

-

Henan, China

-

Name:

-

grain dryer

-

Capacity:

-

15 tons per batch

-

Power:

-

7.5kw

-

Color:

-

yellow

-

Raw material:

-

wheat maize, corn, paddy, rice, sesame, soybean, sorghum

-

Total power:

-

6.5kw

-

Dimension:

-

4228*2750*9871mm

-

Drying time:

-

16h

-

Filled with grain time:

-

1h

-

Heat Source:

-

biomass hot blast stove,diesel stove, natural gas,electric burner

China suppliers rice paddy dryer tower drying plants 32 ton per batch grain dryer mixed folw grain dryer

The machine adopts the low-temperature mixed-flow indirect hot air drying method to dry wheat, soybean, sorghum, rice, and corn . It effectively improves drying speed and drying quality of grain,and reduces equipment idle time.The high heat utilization can remove large amounts of dust from the grain.The water vapor the grain material generated is discharged by the dryer exhaust system,and the fuel consumption is low.This machine is suitable for food processing plants, vocabulary processing plants, farms, grain stations, grain farmers, cooperatives and other user groups.

Advantage s of grain dryer:

1. Dry different materials without replacing parts; electrostatic spray.

2. High thermal efficiency, low unit energy consumption and high productivity.

3. Uniform heat, low thermal damage, low breakage rate, full and complete particles, high seed germination rate.

4. Environmentally friendly hot blast stove, low noise, weak vibration, fuel saving, low cost and long service life.

5. Easy to disassemble and ship, occupying a small area and low labor operation intensity.

6. Simple structure, high quality and low price, low investment cost and no site restrictions.

7. The combustion chamber is made of 310s high temperature resistant stainless steel.

8. PLC control box, fully automatic control system, touch screen display, easy to operate.

The machine with screw conveyors are used to dry small weight grains to achieve the best drying effect. However, t he machine with s elf-flowing circulation base can reduce the breakage rate caused by the collision of grain and conveyor blades,It works better when drying larger grain granules.

|

Model |

SL-15 |

SL- 32 |

|

Capacity |

15 tons per batch |

32 tons per batch |

|

D imension |

4228*2750*9871 mm |

4770*5090*11430 mm |

|

Total power |

6.5kw |

13kw |

|

Net weight of the complete machine |

3200kg |

7500kg |

|

Drying time |

16h |

|

|

Filled with grain time |

1h |

|

|

Heat Source |

biomass hot blast stove, diesel stove, natural gas,electric burner |

|

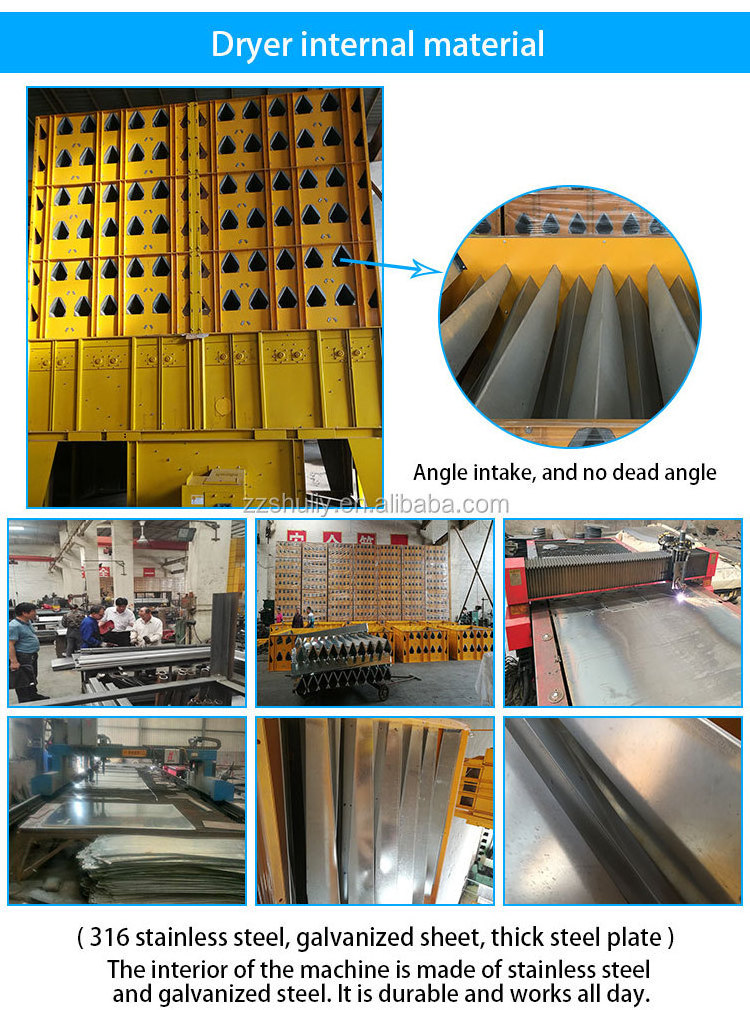

The g rain crops are imported from the top of the tower by bucket elevators , and keep the equipment at full load during operation by the distribution device.The hot air enters the inside of the tower through the induced draft fan.Through the combination of the bottomless V-shaped baffle turned inward and the multi-row V-shaped baffle arranged in a staggered arrangement,the grain crop can be mixed with the hot air,and also serves as an inlet and outlet passage for the dry air.The water vapor generated by drying the material is discharged by the dryer exhaust system, so the fuel consumption is small.

1.online /sale services:

a. super and solid quality

b.fast and punctual delivery

c.standard export package or customized

2.After - sale services:

a.assistance to build your project

b.repairing and maintenance with any problems in the warranty .

c .spare parts and wearing parts for free or with big discount

d . any feedback of the machine can be told us so that we can give you best service

3.Other cooperation services:

a. technology knowledge share

b .business expansion advising

c .video technical support