- Product Details

- {{item.text}}

Quick Details

-

Use:

-

ultrasonic plastic welding

-

Voltage:

-

220 v

-

Power (kW):

-

800w

-

Weight (KG):

-

10 KG

-

Product name:

-

Ultrasonic spot welder

-

Ultrasonic Power:

-

800w

-

Frequency:

-

35KHZ

-

Function:

-

Sealing, welding

-

Item:

-

Ultrasonic generator for welding

-

Keyword:

-

Ultrasonic welding

-

Application:

-

Ultrasonic plastic Welding

-

Suitable Materials:

-

Non-woven,plastic

-

Certificate:

-

CE

-

Operation Mode:

-

Manual + Auto

Quick Details

-

Place of Origin:

-

Beijing, China

-

Max. Welding Thickness:

-

customize

-

Dimensions:

-

customize

-

Use:

-

ultrasonic plastic welding

-

Voltage:

-

220 v

-

Power (kW):

-

800w

-

Weight (KG):

-

10 KG

-

Product name:

-

Ultrasonic spot welder

-

Ultrasonic Power:

-

800w

-

Frequency:

-

35KHZ

-

Function:

-

Sealing, welding

-

Item:

-

Ultrasonic generator for welding

-

Keyword:

-

Ultrasonic welding

-

Application:

-

Ultrasonic plastic Welding

-

Suitable Materials:

-

Non-woven,plastic

-

Certificate:

-

CE

-

Operation Mode:

-

Manual + Auto

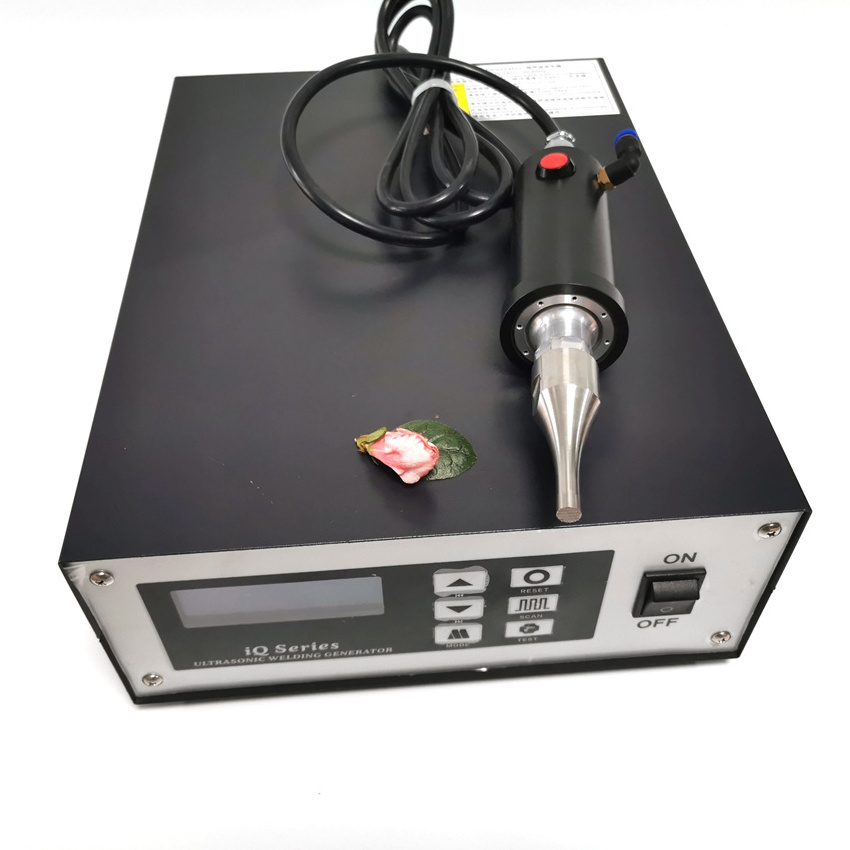

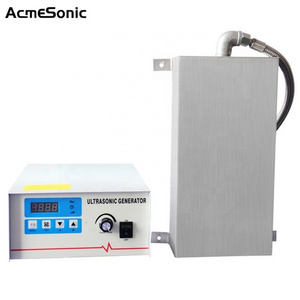

Ultrasonic Spot Welder 28khz/35Khz/40khz 800W With Handheld Titanium Horn For Plastic Parts Welding

Application of ultrasonic plastic welding equipment:

Ultrasonic plastic welding machines are used in the automotive industry, electronics industry, medical industry, home appliance industry, non-woven clothing, office supplies, packaging industry, toy industry, etc. Such as body plastic parts, automobile doors, automobile instruments, lights and mirrors, sun visors, interior parts, filters, reflective materials, reflective road studs, bumpers, cables, plastic filters for motorcycles, and heat dissipation Device, brake fluid tank, oil cup, water tank, fuel tank, air duct, exhaust gas purifier, tray filter plate; plastic electronics: prepaid water meter, communication equipment, cordless phone, mobile phone accessories, mobile phone case, battery case, charger , Valve-controlled sealed maintenance lead-acid batteries, 3-inch floppy disks, U disks, SD cards, CF cards, USB connectors; toys and stationery: folders, photo albums, folding boxes, PP hollow boards, pen sleeves, ink cartridges, toner cartridges; Medical daily use: watches, kitchenware, oral liquid bottle caps, drip bottle caps, mobile phone accessories, gold soft brushes, daily necessities, sanitary products, children's products, air mattresses, hangers, gardening supplies, kitchenware and sanitary ware, gold soft brushes, Welding of shower heads, anti-counterfeiting bottle caps, cosmetic bottle caps, coffee pots, washing machines, air dehumidifiers, electric irons, electric kettles, vacuum cleaners, speaker metal covers, etc.

Principle of ultrasonic plastic welding equipment: The ultrasonic energy is transmitted to the welding area through the upper weldment. Due to the large acoustic resistance at the welding area, that is, the interface between the two weldings, local high temperature will be generated. Due to the poor thermal conductivity of the plastic, it cannot be dissipated in time for a while, gathering in the welding area, resulting in The contact surfaces of the two plastics melt quickly, and after a certain amount of pressure is applied, they fuse into one. After the ultrasonic stops, let the pressure continue for a few seconds to make it solidify and form, thus forming a strong molecular chain, achieving the purpose of welding, and the welding strength can be close to the strength of the raw material.

Features of plastic welding equipment: 1. Novel and fashionable appearance structure design, quick and convenient operation and movement; 2. IC precision control circuit, automatic overload protection system; 3. Four-point balance adjustment of tooling, easy adjustment of welding head; 4. High-quality transducer (vibrator), power output is stronger than peers; 5. There is resonance when no-load and no-load, no need to adjust the welding head frequency; 6. Frequency modulation and frequency automatic compensation circuit; 7. Imported alloy steel/aluminum variable spokes, strong and stable sound waves; 8. Electric lifting body, easy and convenient operation, high strength; 9. Electric precision mechanical limit fine adjustment, with a high accuracy of 0.2mm; 10. With the world's most advanced time welding, deep welding, and collapse welding three welding modes, it is more suitable for high-precision welding occasions.

|

Type |

Power(W) |

Frequency (KHz) |

Input Voltage |

|

OKS-USP -300 |

300W |

28khz |

220V-240V |

|

OKS-USP -300 |

300W |

35KHz |

220V-240V |

|

OKS-USP -300 |

300W |

40khz |

220V-240V |

|

OKS-USP -500 |

500W |

28khz |

220V-240V |

|

OKS-USP -500 |

500W |

35KHz |

220V-240V |

|

OKS-USP -500 |

500W |

40khz |

220V-240V |

|

OKS-USP -800 |

800W |

28khz |

220V-240V |

|

OKS-USP -800 |

800W |

35KHz |

220V-240V |

|

OKS-USP -800 |

800W |

40khz |

220V-240V |

|

OKS-USP -1000 |

1000W |

28KHz |

220V-240V |