- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

2W

-

Brand Name:

-

TKFM

-

Standard or Nonstandard:

-

Standard

-

Body Material:

-

Brass

-

Norminal Pressure:

-

0-1Mpa

-

Connection:

-

Female Thread

-

Drive:

-

Solenoid

-

Applicable Medium:

-

Water/Oil/Gas

-

Applicable Temperature:

-

-10~50℃

-

Voltage:

-

AC220V AC110V DC12V DC24V

-

Size:

-

1/2"-2"

Quick Details

-

Port Size:

-

DN50

-

Warranty:

-

1 years

-

Place of Origin:

-

Liaoning, China

-

Model Number:

-

2W

-

Brand Name:

-

TKFM

-

Standard or Nonstandard:

-

Standard

-

Body Material:

-

Brass

-

Norminal Pressure:

-

0-1Mpa

-

Connection:

-

Female Thread

-

Drive:

-

Solenoid

-

Applicable Medium:

-

Water/Oil/Gas

-

Applicable Temperature:

-

-10~50℃

-

Voltage:

-

AC220V AC110V DC12V DC24V

-

Size:

-

1/2"-2"

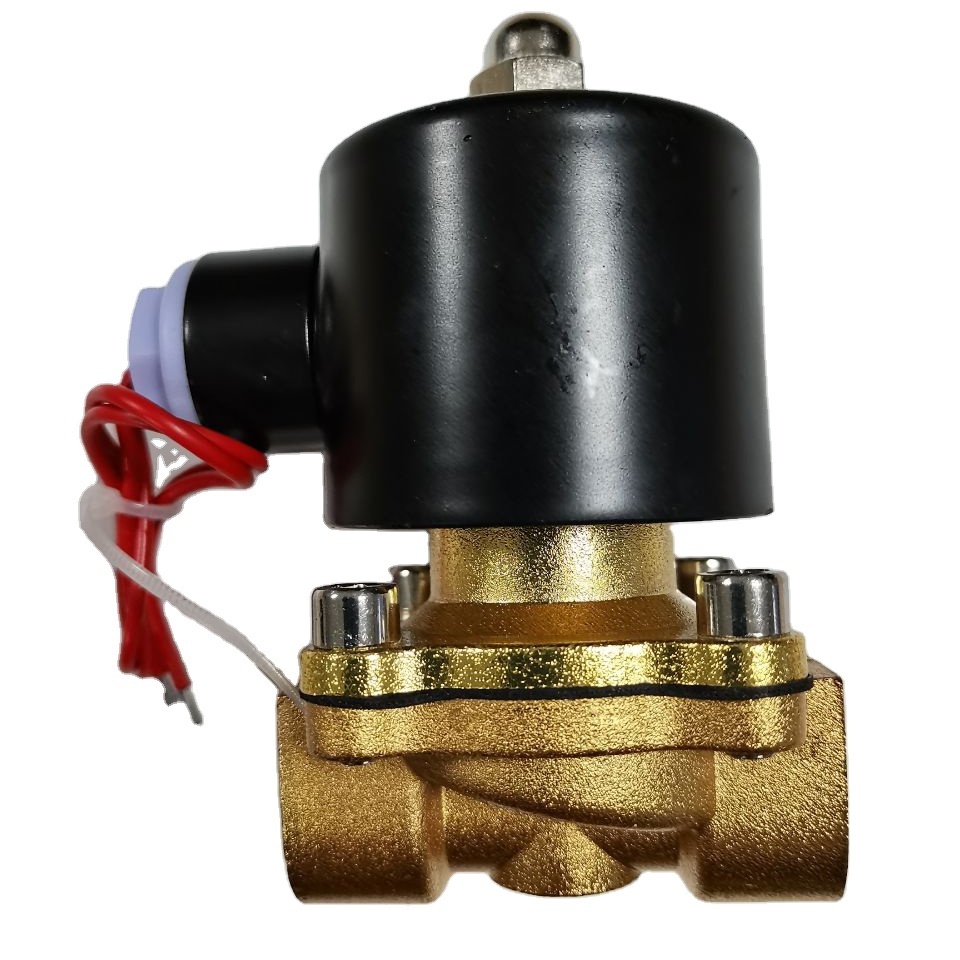

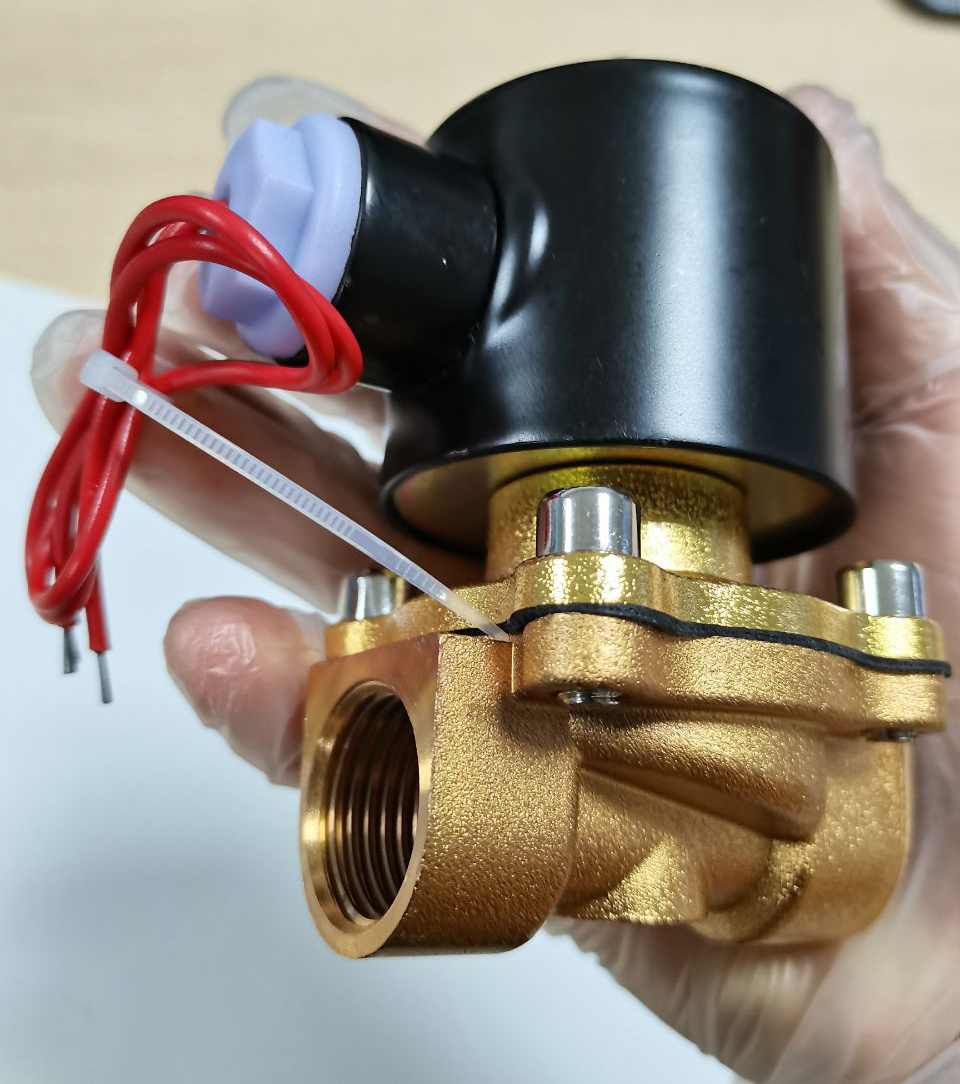

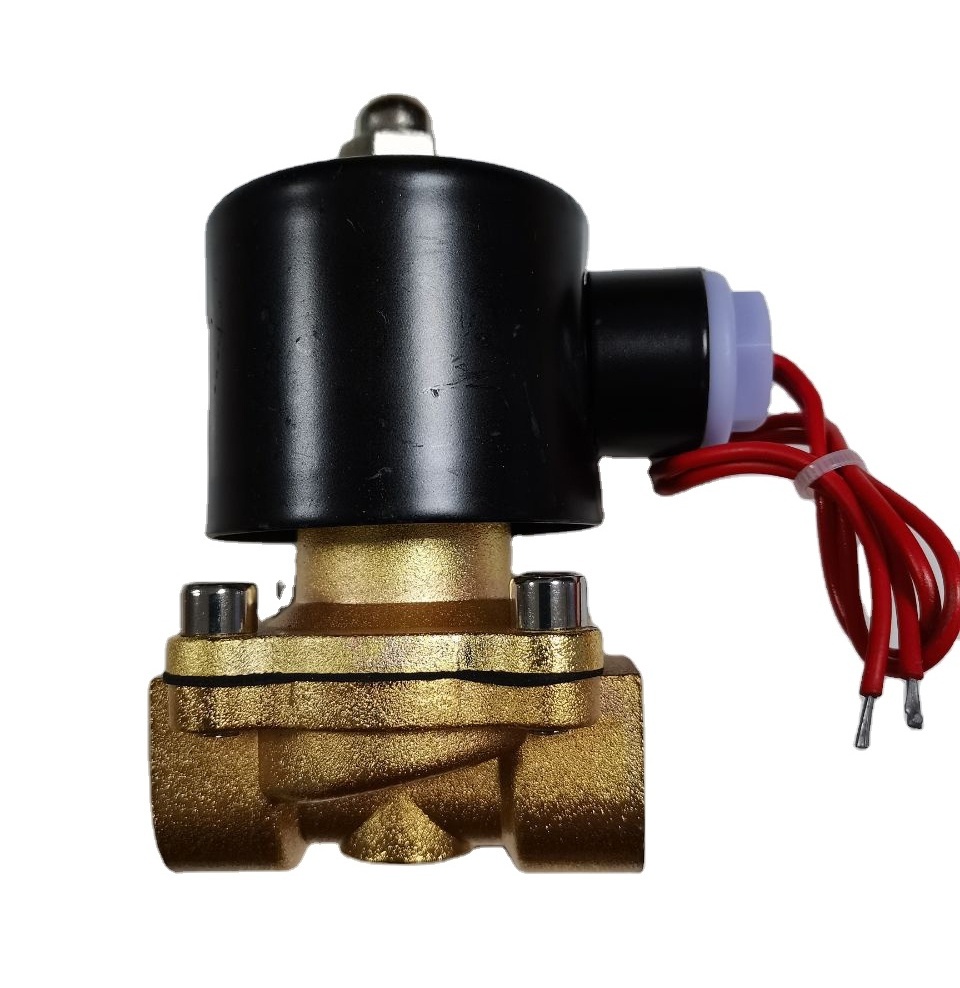

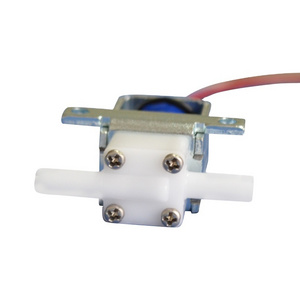

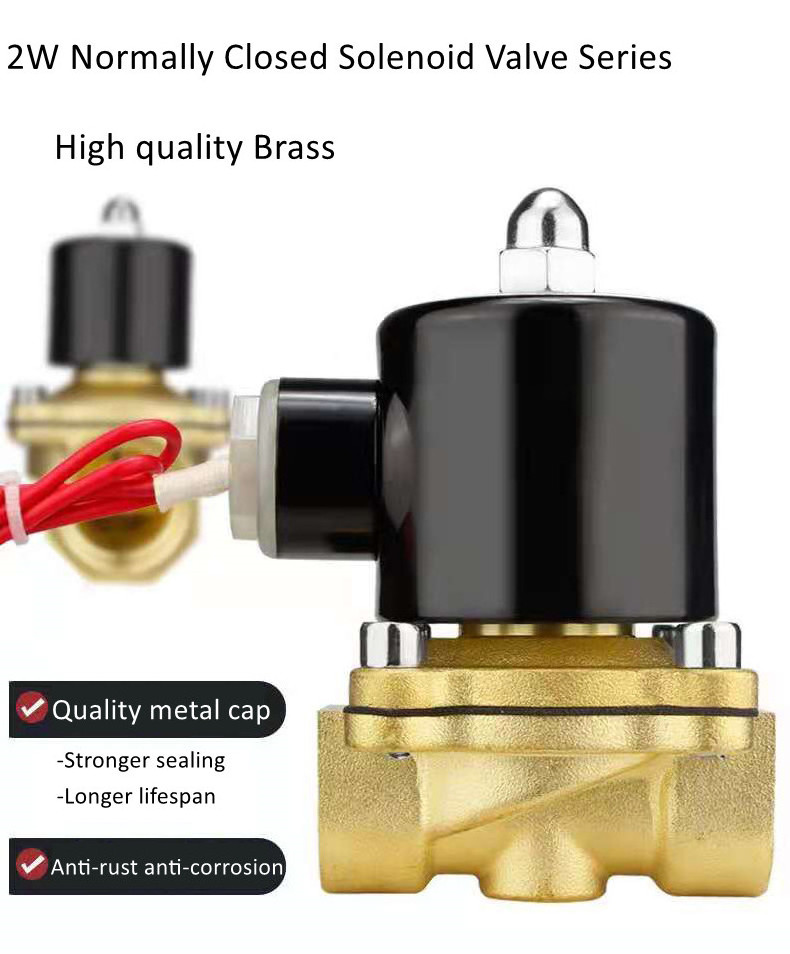

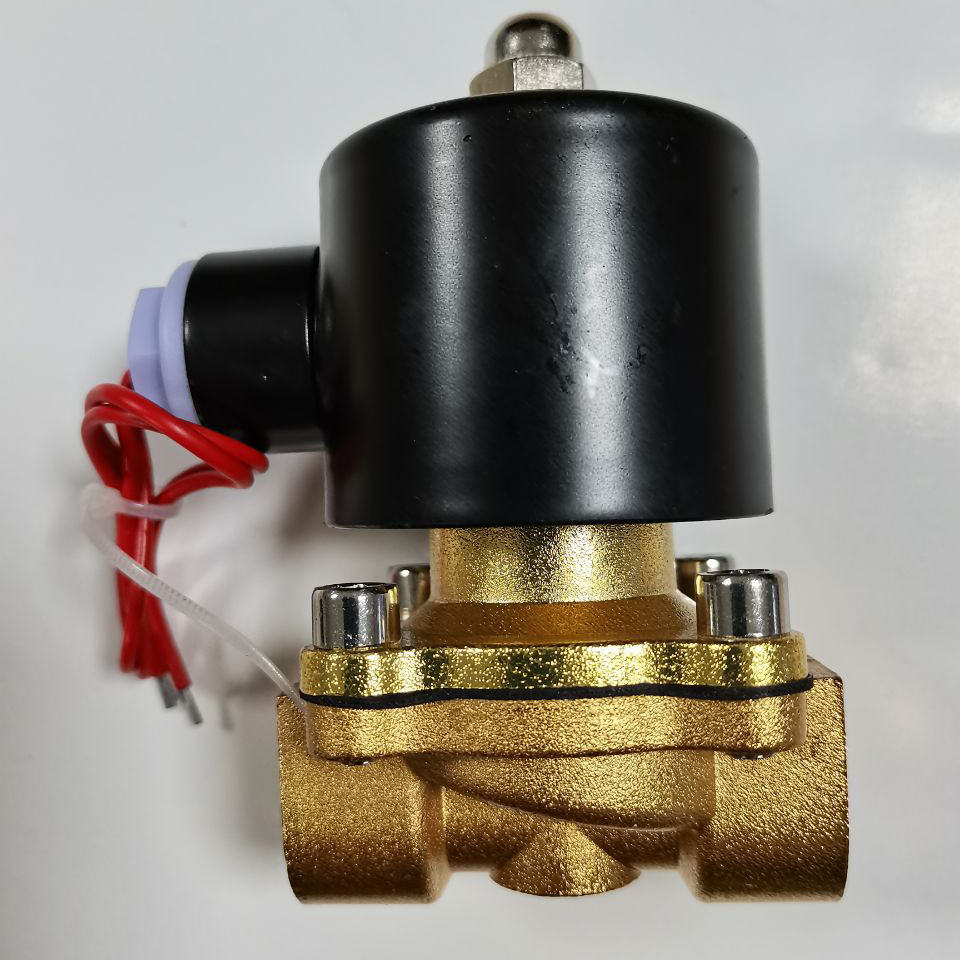

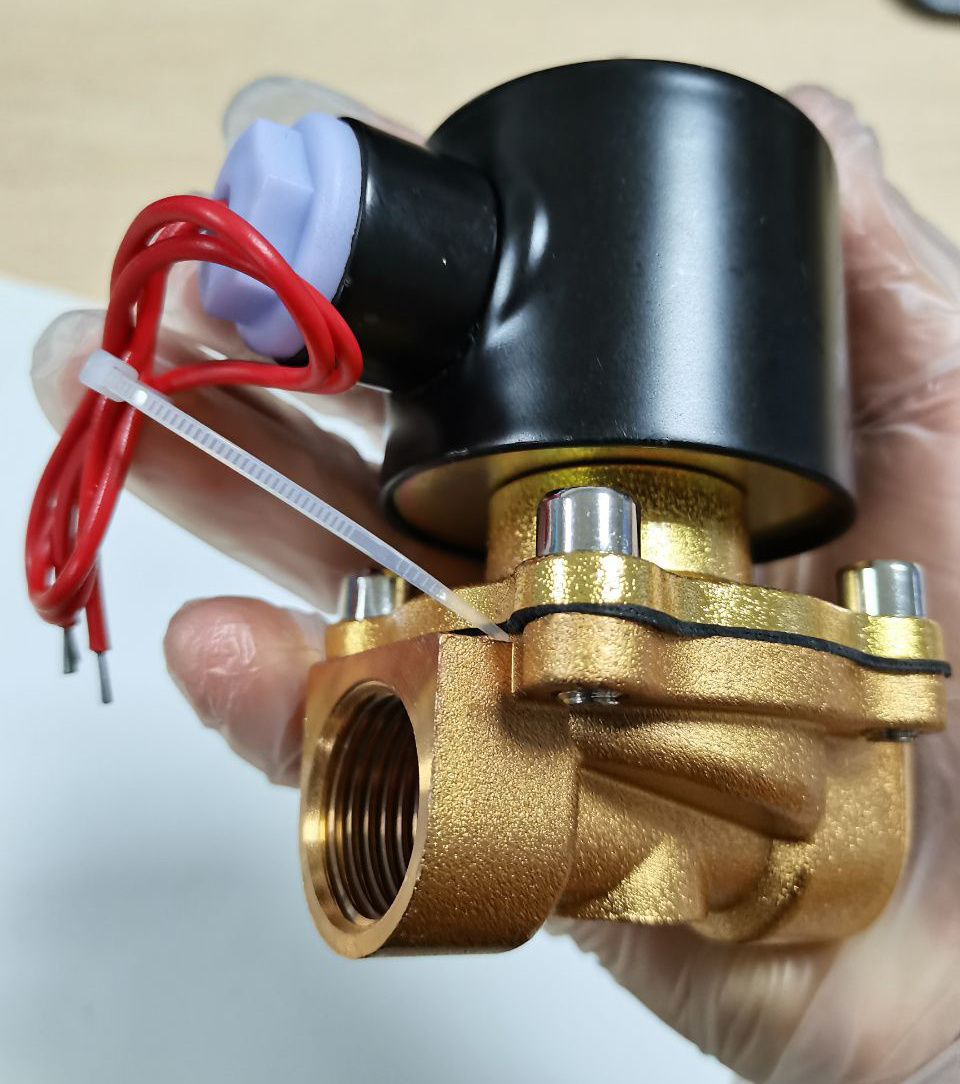

Products Description

SPECIFICATION

|

Name:Solenoid Valve

|

|

|

|

Body material: Forged brass

|

Coil material: copper core coil

|

|

|

Working voltage:AC220V/DC12V/DC24V

|

|

|

|

Temperature:-5℃~80℃

|

Pressure:0-1Mpa

|

|

|

Using way: Straight-through

|

Available range: liquid, gas

|

|

|

Size: 1/4” 3/8” 1/2” 3/4” 1” 1.2” 1.5” 2”

|

|

|

Production Show

Feature

INSTALLATION STEPS

1. Wrap the threaded interface around the raw material tape

2. Intervene the solenoid valve in the direction

3. Connect the power supply according to its standard

4. Test the tightness and its circuit

1. Wrap the threaded interface around the raw material tape

2. Intervene the solenoid valve in the direction

3. Connect the power supply according to its standard

4. Test the tightness and its circuit

INSTALLATION NOTES

1. Try to keep the pipeline clean before installation

2. When installing the solenoid valve, be sure to wrap a suitable raw material tape on the pipe thread and characterize the

position of the solenoid valve

3. Pay attention to the insulation of the circuit

4. Please install the solenoid valve in the direction of water flow

1. Try to keep the pipeline clean before installation

2. When installing the solenoid valve, be sure to wrap a suitable raw material tape on the pipe thread and characterize the

position of the solenoid valve

3. Pay attention to the insulation of the circuit

4. Please install the solenoid valve in the direction of water flow

SOLENOID VALVE FAULT AND TROUBLESHOOTING

|

Solenoid valve not work after energizing?

|

|

|

Check whether the power supply wiring is in good condition and the working pressure is appropriate

|

Re-wire and connect the connector, adjust the valve with the pressure difference commensurate

|

|

Whether the solenoid valve voltage matches the power supply voltage and whether the current is appropriate

|

Equipped with the corresponding power supply DC24V/12V valve, please equip with 2A or more than 2A power supply

|

|

Whether there are impurities that cause the main valve core and moving iron core of the solenoid valve to jam

|

Clean up and replace with new ones if the seals are damaged

|

|

Whether the coil is short-circuited (whether the coil is burned out)

|

Replace with a new coil

|

Our company

Hot Searches