- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Vacorda

-

Flow rate range:

-

0.03m/s~ 12m/s

-

Pipe size:

-

DN25~DN1200mm

-

Accuracy:

-

±1%

-

Medium:

-

Single liquid medium

-

Output signal:

-

4-20mA+RS485

-

Power supply:

-

Battery powered 3000mAh

-

Protection class:

-

Split display IP65; Probe: IP68

-

Cable:

-

Standard 5m

-

Working temperature:

-

-40~+80℃;-40~+130℃

Quick Details

-

Type:

-

Variable Area Water Flowmeters, Variable Area Petrolum Flowmeters, Variable Area Oil Flowmeters

-

Warranty:

-

12 months

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

Vacorda

-

Flow rate range:

-

0.03m/s~ 12m/s

-

Pipe size:

-

DN25~DN1200mm

-

Accuracy:

-

±1%

-

Medium:

-

Single liquid medium

-

Output signal:

-

4-20mA+RS485

-

Power supply:

-

Battery powered 3000mAh

-

Protection class:

-

Split display IP65; Probe: IP68

-

Cable:

-

Standard 5m

-

Working temperature:

-

-40~+80℃;-40~+130℃

Ultrasonic Meter Pure Water Sewage No Breaking Tube High Accuracy Ultrasonic Flowmeter

Accessories

1. Carrying Case*1pc.

2. Transmitter (Electronic)*1pc.

3. Transducer (Sensor) *1 pair.

4. Mounting track *1 set, ST or DT

5. Pipe straps *2 pairs.

6. Coupling compound (Grease)*1 pc, Battery charge*1pc , Output cable*1pc and Tapeline*1

Parameters

|

Pipe size |

DN25—DN1200mm |

|

Flow rate |

0.03m/s——12m/s |

|

Accuracy |

±1% |

|

Medium |

S ingle liquid medium |

|

Output signal |

4-20mA + RS485 |

|

Power supply |

Battery powered 3000mAh |

|

Protection class |

Split display IP65; Probe: IP68 |

|

Cable |

S tandard 5m |

|

Working temperature |

-40~+80℃; -40~+130℃ |

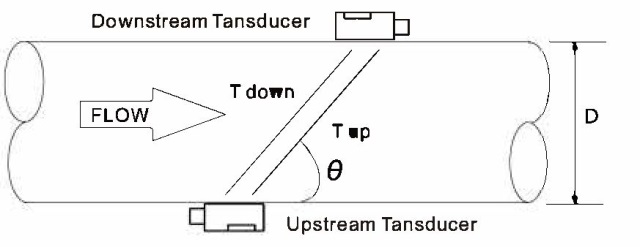

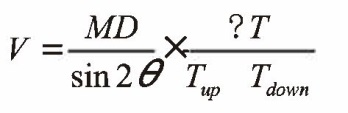

Measuring Principle

This series of ultrasonic flowmeter is an industrial time-difference type ultrasonic

flowmeter. It applies the latest industrial-level PFGA 700-thousand- gate-array chip , which extremely improves the signal sampling frequency and bubble tolerance rate; the self-developed TGA technology makes it be capable of dealing with more complex

logic and calculation to provide more accurate and faster measurements, and ensures the flowmeter could endure non-continuous bubbles or impurities within 5 sec. In addition, it could be installed and operated in a convenient way with no need to break the pipe or cut off the fluid or stop work. Time-difference type ultrasonic measurement indicates determining the fluid flow along the average velocity with the time difference between two ultrasonic signals transmitting downstream or upstream in the same stroke.

In which,

v

Fluid velocity

M

Ultrasonic reflections

D

Pipe diameter

θ

Included angle between ultrasound signal and fluid

Tup

Time that downstream transducer sends signal to

upstream

Tdown

Time that upstream transducer sends signal to

downstream

T =Tup-Tdown

Application Scope

It mainly applies for measuring the flow of homogeneous medium fluid in the following fields:

Domestic wastewater flow measurement, crude oil flow measurement, cementing slurry flow measurement, oily sewage flow measurement in oil fields, water injection flow measurement in oil wells, raw water flow measurement in rivers and reservoirs, tap water flow measurement, process flow measurement of petrochemical products, industrial circulating water flow measurement, water consumption measurement in production, mineral slurry flow measurement, pulp flow measurement, chemical flow measurement, circulated cooling water flow measurement, generating coil cooling water flow measurement (super small diameter), juice flow measurement, milk flow measurement, and so on.

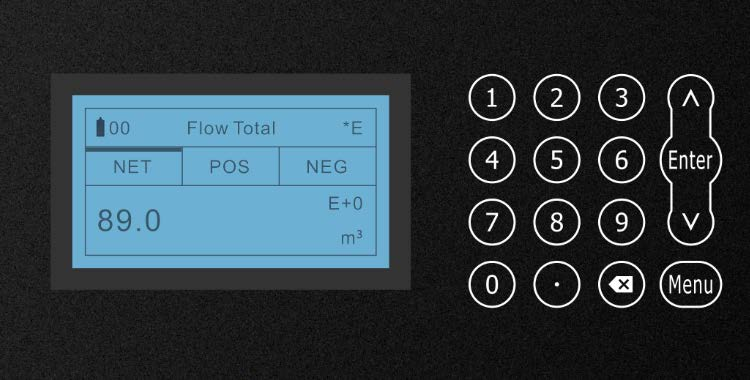

Keyboard Operation

Use digits [0~9] and [ . ] to input digits or menu number.

[

] key is us ed for left backspace or deleting the characters on left.

[ ] and [ ] keys are used for entering the pre vious or next menu; the key is plus or minus when

inputting digits.

[Menu] key is used for choosing menus. Press the key and then input menu number to enter

related menu.

[Enter] key is used for entering the edit mode and confirm the corrections.

4.3.2 Keyboard Operation Methods

The flowmeter menu is divided into six modules according to the functions and field demands.

You can directly input the menu number to enter the menu and you also can switch through [ ]

and [ ] keys.

If you need to correct the flowmeter parameters, please firstly switch to related menu, find out

the parameter you want to correct and then press [Enter] to confirm; input the data and then

press [Enter] to confirm your corrections.