- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

800 r.p.m

-

Spindle Bore(mm):

-

enquiry us

-

Width of bed (mm):

-

45 mm

-

Spindle Motor Power(kW):

-

22-30

-

Travel (X Axis)(mm):

-

600 mm

-

Travel (Z Axis)(mm):

-

500 mm

-

Place of Origin:

-

China

-

Brand Name:

-

DONGS

-

Weight (KG):

-

10800

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

VTC1000

Quick Details

-

Type:

-

VERTICAL

-

Max. Length of Workpiece (mm):

-

1000

-

Year:

-

2023

-

Max. Spindle Speed (r.p.m):

-

800 r.p.m

-

Spindle Bore(mm):

-

enquiry us

-

Width of bed (mm):

-

45 mm

-

Spindle Motor Power(kW):

-

22-30

-

Travel (X Axis)(mm):

-

600 mm

-

Travel (Z Axis)(mm):

-

500 mm

-

Place of Origin:

-

China

-

Brand Name:

-

DONGS

-

Weight (KG):

-

10800

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

VTC1000

Product Description

Specification

|

item

|

Unit

|

VTC1000

|

|

Maximum rotation diameter of workpiece

|

mm

|

1000

|

|

Block type

|

mm

|

900

|

|

Hydraulic chuck diameter

|

mm

|

800

|

|

Spindle speed

|

rpm

|

50-800

|

|

Spindle model

|

/

|

A2-11

|

|

Spindle output torque

|

NM

|

1050

|

|

Vertical movement distance of tool carrier

|

mm

|

700

|

|

Horizontal moving distance of tool rest

|

mm

|

-50-550

|

|

Track width

|

mm

|

55 Heavy load roller

|

|

X/Z-axis fast moving speed

|

m/min

|

15/12

|

|

Tool holder form

|

/

|

4/8-station servo turret/multiple spindle cutter

|

|

Cutter bar section

|

mm

|

32x32 Boring tool holder 40/50

|

|

Main motor power

|

KW

|

22-30(Low frequency high torsion)

|

|

X power and torque of feed motor

|

KW/NM

|

2.8/18

|

|

Y power and torque of feed motor

|

KW/NM

|

2.8/18

|

|

Diameter of X/Z axis ball screw

|

mm

|

5010/5010

|

|

Repeated positioning accuracy of machine tool

|

mm

|

±0.005

|

|

The weight of the machine tool is about

|

T

|

10.8

|

|

Outline dimension of machine tool

|

m

|

2.9*2.9*3.5

|

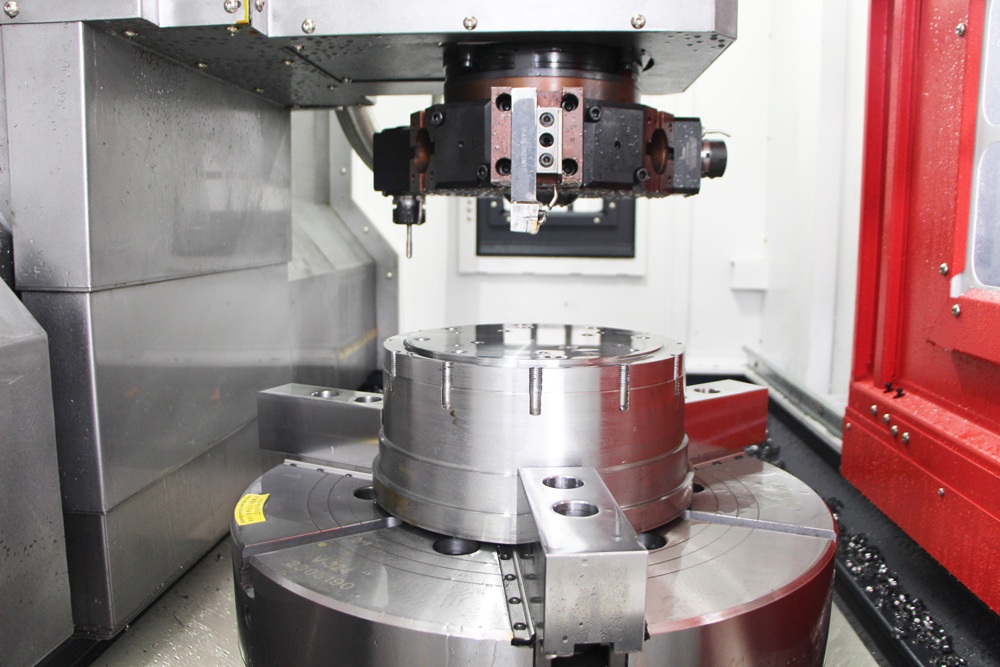

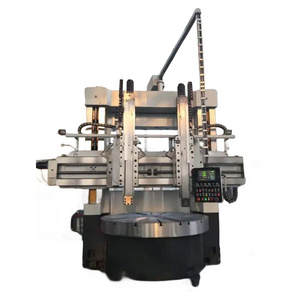

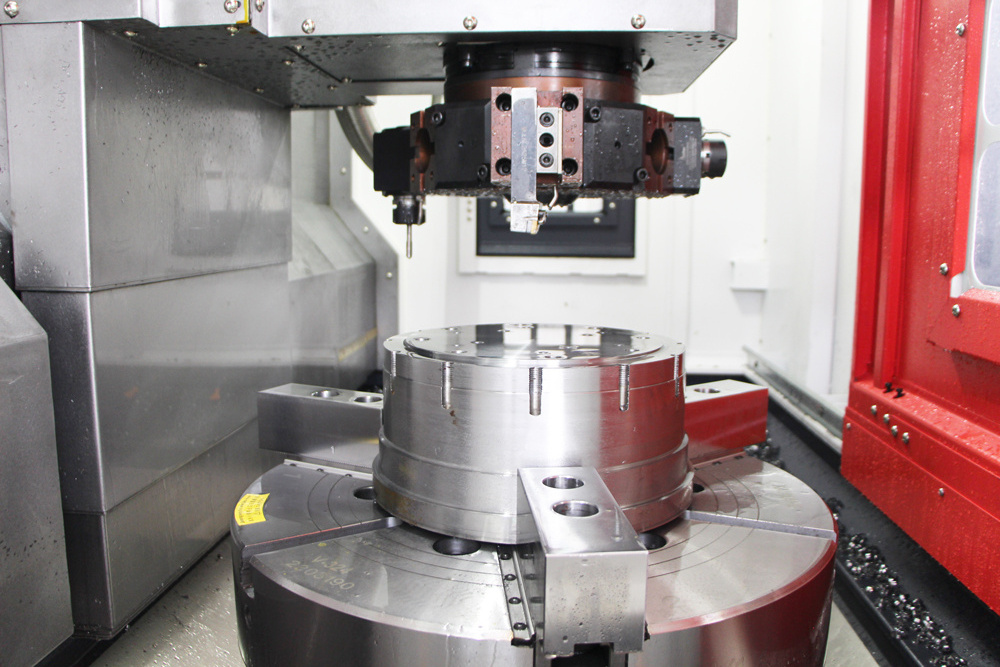

Details Images

Main structural performance of machine tools

★This machine tool consists of a bed, a base, a workbench, a crossbeam, a crossbeam lifting mechanism, a tool holder, a CNC system, a ball screw, an electric motor, a hydraulic system, an electrical system, a button station, etc.

★The main drive of this machine tool is driven by a main motor. The spindle of the worktable is equipped with NN3000 double row cylindrical roller bearings on the upper and lower parts. The inner ring has a taper that can be adjusted, and the radial clearance ensures smooth operation of the spindle at high speed accuracy. The main drive mechanism and worktable guide rail are lubricated by pressure oil. The servo motor is decelerated by a planetary reducer to increase torque, and then drives the ball screw to move the slide and pillow, achieving X and Z axis feed. Horizontal and vertical manual feed are controlled by electronic handwheels.

★The crossbeam is firmly clamped onto the column. Press the button to stand on the crossbeam lifting button, and use the electromagnetic slide valve to change the direction of oil intake, so as to relax the crossbeam and move it up and down by the motor.

Hot Searches