- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

UT-800

-

Power:

-

25KW

-

Marketing Type:

-

New Product 2024

-

Weight (KG):

-

1200 kg

-

Name:

-

Aluminum Plastic Recycling Machine

-

Material / Metal Processed:

-

waste medical blister

-

Keyword:

-

Aluminum Plastic Recycle

-

Input Materials:

-

medical blister aluminum plastic

-

Application:

-

aluminum and plastic separate, Aluminum-plastic waste trea

-

Function:

-

Aluminum Plastic Recycling

-

Product name:

-

Metal Powder&Plastic Powder

-

Key Words:

-

Aluminum Plastic Separating Plant

-

Voltage:

-

220/380V

-

Tell:

-

008618037187350

Quick Details

-

Production Capacity:

-

2000L/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

UT

-

Model Number:

-

UT-800

-

Power:

-

25KW

-

Marketing Type:

-

New Product 2024

-

Weight (KG):

-

1200 kg

-

Name:

-

Aluminum Plastic Recycling Machine

-

Material / Metal Processed:

-

waste medical blister

-

Keyword:

-

Aluminum Plastic Recycle

-

Input Materials:

-

medical blister aluminum plastic

-

Application:

-

aluminum and plastic separate, Aluminum-plastic waste trea

-

Function:

-

Aluminum Plastic Recycling

-

Product name:

-

Metal Powder&Plastic Powder

-

Key Words:

-

Aluminum Plastic Separating Plant

-

Voltage:

-

220/380V

-

Tell:

-

008618037187350

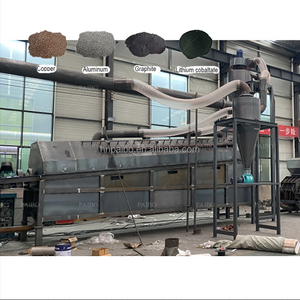

Fully Automated Waste Car Lead Acid Battery Recycling Machine Provided UT Used Mobile Phones for Sale in France 2 Years 1200

Used for separating metals and non-metals in materials, such as waste circuit boards, CCL, circuit boards, bits and

pieces, and recovering metals and resin powder in those materials.

1. The entire assembly line uses the PLC intelligent programming automatic control and man-machine interface touch screen, so that the even feeding of the entire production line and coordinated work can be realized.

2. Compact structure, reasonable layout, stable performance, noise reduction treatment of the crushing equipment.

3. The crushing part uses shredding, smashing and crushing processes, and circulating water cooling is used inside and outside the crushing chamber.

4. Use the negative pressure feeding system and pulse dust removal system to purify the working environment.

5. The sorting part adopts the proportion sorting combined with the static careful selection, so that the metal recovery rate can reach up to more than 99%.