- Product Details

- {{item.text}}

Quick Details

-

Type:

-

insulation

-

Rated Voltage:

-

10kv-800kv

-

Tensile Strength:

-

High

-

Sample:

-

Free

-

lead time:

-

about 7-15 days

-

logo:

-

yes

-

supply type:

-

customization

-

Standard:

-

IEC61109

-

Certificate:

-

ISO9001,CE,Rosh

-

Product name:

-

frp rod

-

Feature:

-

Insulation, chemical resistant,Good electrical performance

-

Special advantage:

-

epoxy resin ECR glass

Quick Details

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

TID POWER

-

Model Number:

-

TECR

-

Type:

-

insulation

-

Rated Voltage:

-

10kv-800kv

-

Tensile Strength:

-

High

-

Sample:

-

Free

-

lead time:

-

about 7-15 days

-

logo:

-

yes

-

supply type:

-

customization

-

Standard:

-

IEC61109

-

Certificate:

-

ISO9001,CE,Rosh

-

Product name:

-

frp rod

-

Feature:

-

Insulation, chemical resistant,Good electrical performance

-

Special advantage:

-

epoxy resin ECR glass

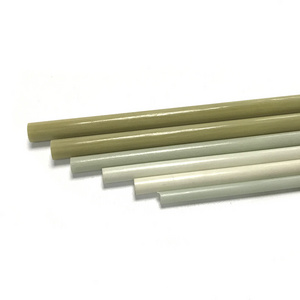

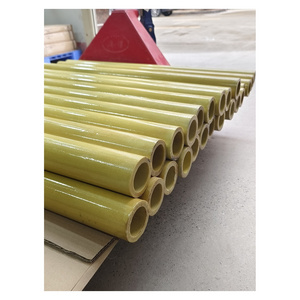

Core Rod is the major component of the polymer insulator. It is essential for the insulator as it provides the mechanical strength as well as electrical insulation properties. In the recent days this core rod is widely made up of glass fibre reinforced plastic (FRP).

The following are the properties possessed by FRP:

- High Thermal Insulation

- Cost effective

- Good Chemical and corrosion resistance

- Can be bonded readily with dissimilar materials

- High mechanical strength at low weight

- Technique – Pultrusion Process

- Standard – IEC61109, GB, SGS

Technical Parameters

| NO. | Parameter | Unit | Specification Value |

| 1 | Density (at 20℃±2℃) | g/cm3 | ≥2.2 |

| 2 | Water absorption rate(at 20℃±2℃) | % | ≤0.05 |

| 3 | Tensile Strength | Mpa | ≥1200 |

| 4 | Bending Strength | Mpa | ≥960 |

| 5 | Dye Penetrated Test | Min | ≥15 |

| 6 | Water diffusion Test | mA | ≤0.1 |

| 7 | Shearing Strength alone laminas | Mpa | ≥50 |

| 8 | Volume Resisivity(140℃,96h) | Ω·M | ≥1010 |

| 9 | DC withstand voltage(10mm) | kV | ≥50 |

| 10 | Lighting Surge withstand voltage | Times | ≥50 |

| 11 | Bending Strength at heating Conditions | Mpa/150℃ | ≥350 |

| 12 | Torsion Strength | Mpa | ≥800 |

Exiting rod diameter

machining process

1- Continuous roll of reinforced fibers/woven fiber mat

2 - Tension roller

3 - Resin Impregnator

4 - Resin soaked fiber

5 - Die and heat source

6 - Pull mechanism

7 - Finished hardened fiber reinforced polymer

Routine Test Equipment

How to choose a good core rod?