- Product Details

- {{item.text}}

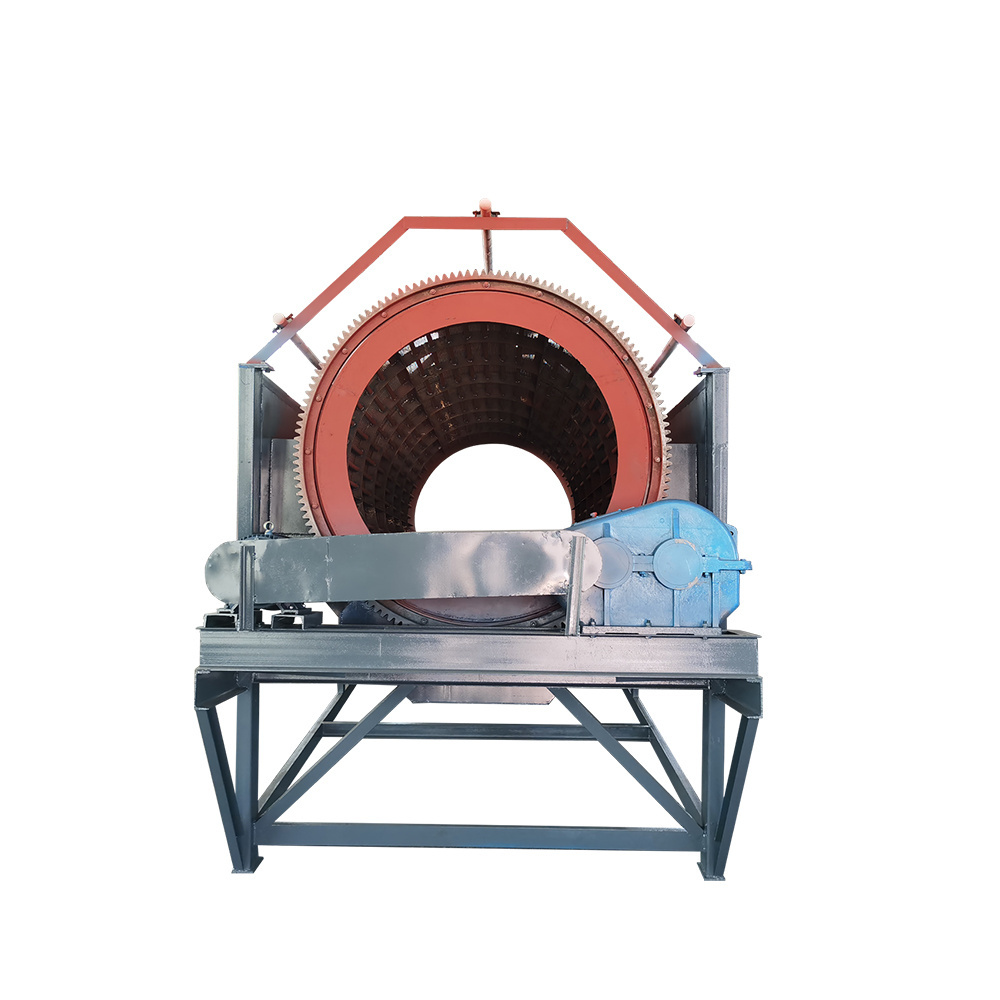

Quick Details

-

Voltage:

-

220v

-

Dimension(L*W*H):

-

2520*1020*1860mm

-

Weight:

-

1600 KG

-

Keyword:

-

Gold Washing Vibrating Screen

-

Product name:

-

Tromme Screen

-

Color:

-

Customers' Request

-

Usage:

-

Mining Separatoion

-

Installation:

-

Engineer Guide

-

Capacity:

-

15-600t/h

-

Recovery rate:

-

99 %

-

Material:

-

Steel

Quick Details

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Jianlong

-

Voltage:

-

220v

-

Dimension(L*W*H):

-

2520*1020*1860mm

-

Weight:

-

1600 KG

-

Keyword:

-

Gold Washing Vibrating Screen

-

Product name:

-

Tromme Screen

-

Color:

-

Customers' Request

-

Usage:

-

Mining Separatoion

-

Installation:

-

Engineer Guide

-

Capacity:

-

15-600t/h

-

Recovery rate:

-

99 %

-

Material:

-

Steel

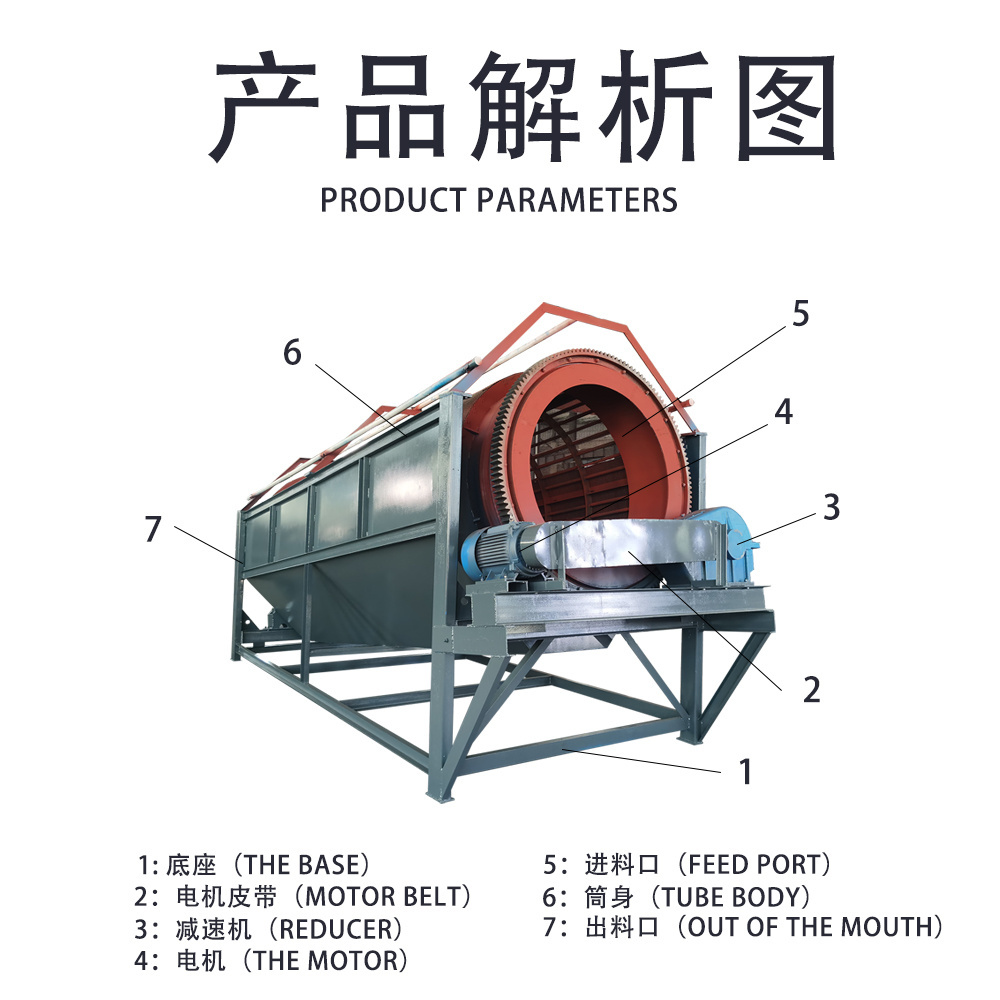

The roller device is tilted on the frame. The motor is connected with the drum device by a reducer through a coupling and drives the drum device to rotate around its axis. When the material into the drum device, due to the tilt and rotation of the drum device, the screen surface of the material turnover and rolling, so that qualified material (screen products) through the bottom of the end of the drum discharge mouth, unqualified material (screen products) through the end of the drum discharge mouth. Due to the material in the roller of the turnover, rolling, so that the material stuck in the screen can be ejected, to prevent the screen clogging

Scope of application

One. Stone yard used for grading large and small stones. And the separation of soil and stone dust.

Two. Sand yard with sand and stone separation.

Three. Coal industry for the separation of lump coal and coal powder and coal washing (part of coal washing machinery)

Four. Chemical industry, mineral processing industry for the size of the block classification and separation of powdery substances.

Operation and maintenance .

1, boot must first open the cage roller screen, and then open the feeding equipment; Reverse when parking;

2. The bearing seat and gearbox should be regularly checked for lubrication, and timely refueling and oil change. Large shaft bearings use no. 2 lithium grease, normally, every two months to add grease, the amount of filling should not be too much, otherwise it is easy to cause the bearing overheating. Bearings should be cleaned and inspected once a year.

Ganzhou Jianlong Machinery Equipment Co., LTD

Ganzhou Jianlong Machinery equipment Co., Ltd. is an over 30 years professional manufacturer and exporter of mining machinery for crushing, screening, grinding, flotation,separation etc. in China. have a complete service system which can provide customer full service in mining field and after sales service.By now, equipments and services are exported to over 60 countries,include America, Russia, India, Africa,Brazil, Chile,South Africa,Zambia etc. Sincerely welcome customers to visit our factory.

Customer Photos

Successful Cases

One Stop solution for beneficiation plant service:

1.Engineering consulting available,it makes clients have a comprehensive understanding of beneficiation plant,including mine value,useful elements,mineral processing technology,plant scale,essential equipments,etc.

2.Arrange mineral beneficiation experiment after received the material sample and beneficiation test report will be done after test.

2.Arrange mineral beneficiation experiment after received the material sample and beneficiation test report will be done after test.

3.After reaching agreement with client,we start to engineering design,including planning,investigation,data collection, project evaluation etc. and then comes up with design scheme of beneficiation plant construction and working drawings.

4.Manufacturing the necessary equipments and arrange the shipment.

4.Manufacturing the necessary equipments and arrange the shipment.

5.Complete services for Installation and commissioning and technical training(operating training,common problem solving training).

After-sale Service:

Regularly visit customers to provide after- sale technical supports and to solve problems of beneficiation plant. For equipments supplied,we could provide one-year warranty and provide spare parts with preferential price in the long term and be responsible for any problems with the them.

●Pre-sales service:

We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

●Sales service:

Send technicians to the site to guide the installation and commissioning, train the operators, and

complete the acceptance with you.

complete the acceptance with you.

●After-sales service:

To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

●Lifelong service:

One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

●How is the quality of your products?

Answer:

Our products are manufactured strictly according to national and international standard, and we will take a test on every equipment before delivery.

●How about the Guaranteed?

Answer:

All of our products are guaranteed for one year. If products quality is not consistent with the description as wedescribed or the promise before you place order, we promise 100% refund.

●How about price?

Answer:

For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

●How about the service and payment terms?

Answer:

We can accept T/T or other payment ways you request; 40% deposit, 60% balance before delivery, which is

international trade practice; Finished product pictures will provide to customers before delivery.

international trade practice; Finished product pictures will provide to customers before delivery.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches