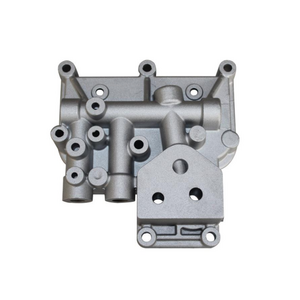

- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

Aluminum die casting parts

-

Material:

-

Aluminum

-

Certification:

-

IATF16949

-

Surface treatment:

-

Custom

-

Mould life:

-

100000

-

MOQ:

-

1000 Pcs

-

Application:

-

Machinery Parts

-

Machinery test report:

-

Provide

-

Cnc machining or not:

-

Cnc machining

-

Style:

-

Modern

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

AKH

-

Model Number:

-

OEM-casting

-

Product Name:

-

Aluminum die casting parts

-

Material:

-

Aluminum

-

Certification:

-

IATF16949

-

Surface treatment:

-

Custom

-

Mould life:

-

100000

-

MOQ:

-

1000 Pcs

-

Application:

-

Machinery Parts

-

Machinery test report:

-

Provide

-

Cnc machining or not:

-

Cnc machining

-

Style:

-

Modern

Details Images

|

Product Name:

|

Aluminum sand casting parts/die casting/gravity casting

|

|

Material:

|

Aluminum alloy A356,adc12,a380, AlSi9Cu3,YL102and others

|

|

Mold led time

|

25-30days,according to quantity and design drawings

|

|

Sample

|

we offer free samples.

|

|

Drawing file

|

.pdf.stp.igs.

|

|

MOQ

|

1000pcs

|

|

Surface Finished:

|

Painting,polished,shot blasting

|

|

Service

|

offer assembly if customer's need

|

Application

Introduction to die casting factory:

Aluminum die cast process is a process in which the molten liquid of aluminum alloy is poured into the mold and solidified into a casting under the action of pressure.

Our factory has 280-1260 tons of cold die casting machine, which adopts high-pressure casting. The product produced by us not only have high surface tolerance grade, good roughness and high strength, but also have high productivity,at least 50000 pcs per month,and our product scrap rate is controlled within 2%. At the same time, we are also equipped with a CMM to detect and control the product tolerance and size within the range of customer requirements,and it's toelrance is 0.0005.We also provide assembly service if customers requires.

Our factory also specialized in customized production and processing of various metal parts, such as automobile and motorcycleprecision die castings spare parts, customized led light housings, electrical parts, communication equipment spare parts,fire-fighting accessories, furniture metal accessories, etc. Some of these metal parts will require high precision to meet the product assembly requirements, so our company is equipped with 24 CNC machining centers and more than 22 CNC milling machines and lathes.The minimum accuracy of our CNC machining machine can reach 0.0005.

Our factory has 280-1260 tons of cold die casting machine, which adopts high-pressure casting. The product produced by us not only have high surface tolerance grade, good roughness and high strength, but also have high productivity,at least 50000 pcs per month,and our product scrap rate is controlled within 2%. At the same time, we are also equipped with a CMM to detect and control the product tolerance and size within the range of customer requirements,and it's toelrance is 0.0005.We also provide assembly service if customers requires.

Our factory also specialized in customized production and processing of various metal parts, such as automobile and motorcycleprecision die castings spare parts, customized led light housings, electrical parts, communication equipment spare parts,fire-fighting accessories, furniture metal accessories, etc. Some of these metal parts will require high precision to meet the product assembly requirements, so our company is equipped with 24 CNC machining centers and more than 22 CNC milling machines and lathes.The minimum accuracy of our CNC machining machine can reach 0.0005.

Recommend Products

Hot Searches