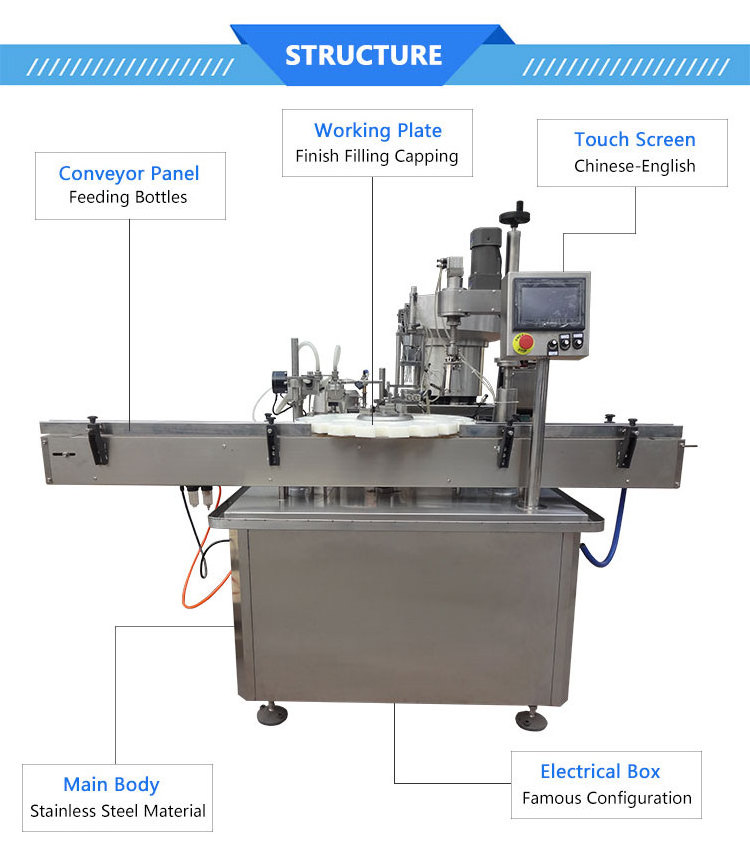

1. Filling:

via a conveyor belt to carry the bottom of the bottle to the filling head and the bottle was blocked by the dial to

step forward, this time-synchronous filling heads into the bottom of the bottle and completed filling by a quantitative piston

pump.

2. Put Cover:

caps vibrate through an electromagnetic oscillator, so cover up the delivery chute, through the bottle fell to the

track, and then was pressed by press head.

3. Capping:

filling finished bottle-fed by a conveyor belt on the turntable, the turntable through the sheave box for intermittent

operation. When a bottle with a cap carries to the bottle caper housing for intermittently pauses, the capping head will be

pressed lower by a cam and rotate clockwise, thus boosting the cap tightened.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%, ±1%

-

Voltage:

-

380

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Boom

-

Dimension(L*W*H):

-

2500*1450*1650mm

-

Weight:

-

600 KG

-

Keyword:

-

Automatic Liquid Filling Capping Machine

-

Filling Capacity:

-

5-50ml (replace filling pump)

-

Productivity:

-

60-70 bottles/min (customization)

-

Filling Nozzles:

-

1 Head or customized

-

Function:

-

Filling + Capping

-

Control System:

-

Touch Screen + PLC Control

-

Feature:

-

High Precision Filling Level

-

Bottle Type:

-

PET Plastic Bottle Glass Bottle

-

Suitable for:

-

Vial, Eyedrop, Essential Oil, Dropper Bottle, etc.

Quick Details

-

Machinery Capacity:

-

4000BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Milk, Water, Oil, Juice, Powder

-

Filling Accuracy:

-

±1%, ±1%

-

Voltage:

-

380

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Boom

-

Dimension(L*W*H):

-

2500*1450*1650mm

-

Weight:

-

600 KG

-

Keyword:

-

Automatic Liquid Filling Capping Machine

-

Filling Capacity:

-

5-50ml (replace filling pump)

-

Productivity:

-

60-70 bottles/min (customization)

-

Filling Nozzles:

-

1 Head or customized

-

Function:

-

Filling + Capping

-

Control System:

-

Touch Screen + PLC Control

-

Feature:

-

High Precision Filling Level

-

Bottle Type:

-

PET Plastic Bottle Glass Bottle

-

Suitable for:

-

Vial, Eyedrop, Essential Oil, Dropper Bottle, etc.

PRODUCT DESCRIPTION

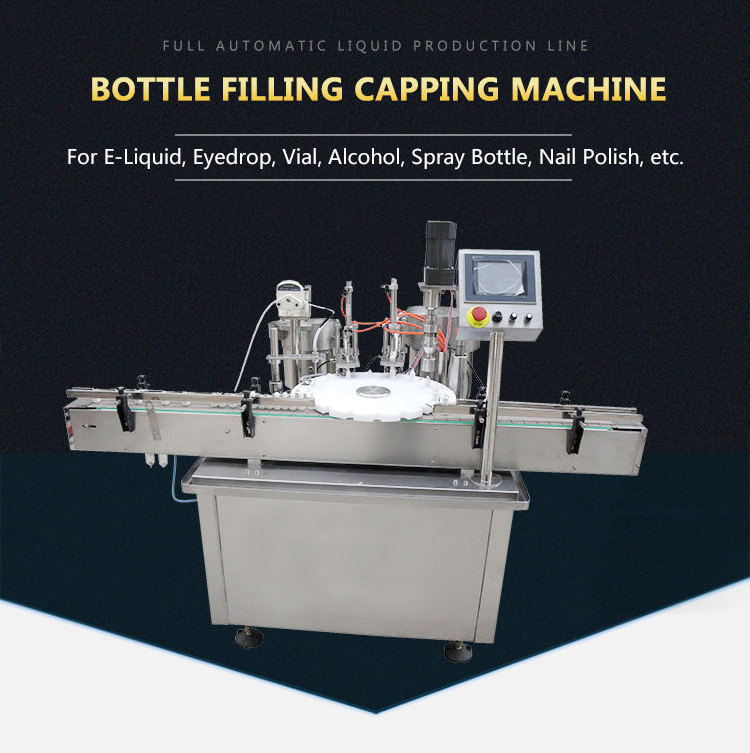

Fully Automatic 10 ML Liquid Vial Bottle Filling Capping Machine

The filling and capping machine is a new generation utility product, developed from the most advanced technology to suit market demand, the machine adopts an SS304 volumetric injection pump, auto cap orienting, and capping together. With the economic utility and low plant cover, the machine is widely applied to liquid packing in the market of pharmaceuticals, pesticides, chemicals, foodstuffs, cosmetics, etc, to meet the requirement of GMP.

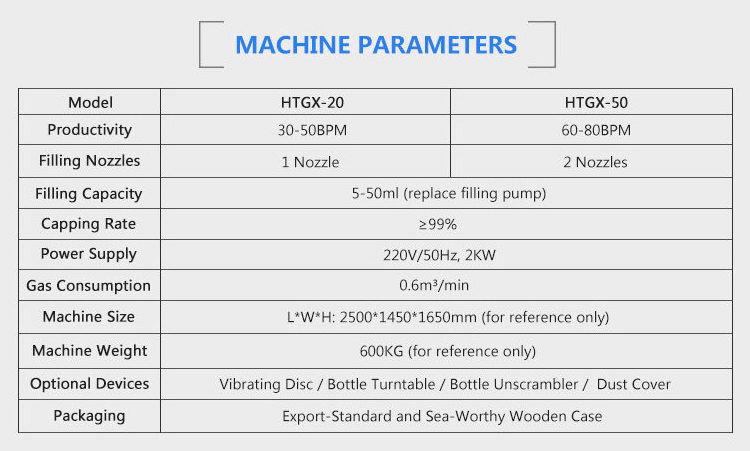

SPECIFICATIONS

|

Parameters

|

Number Reference

|

|

|

|

Model

|

HTGX-20

|

HT-NC-2, HT-KC-2

|

|

|

Productivity

|

30-50BPM

|

60-80BPM

|

|

|

Filling Head

|

1 Head

|

2 Heads

|

|

|

Filling Volume

|

5-50ml (replace filling pump)

|

|

|

|

Filling Accuracy

|

±1%

|

|

|

|

Control System

|

Touch Screen + PLC Control

|

|

|

|

Gas Consumption

|

0.6m³/min

|

|

|

|

Power

|

3KW

|

|

|

|

Voltage

|

AC380V/220V, 50Hz/60Hz

|

|

|

|

Machine Dimension

|

2500*1450*1650mm (for reference only)

|

|

|

|

Machine Weight

|

600KG (for reference only)

|

|

|

FEATURES AT A GLANCE

Working Process:

RECOMMEND PRODUCTS

PACKAGING

COMPANY PROFILE

Hot Searches