- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380 v

-

Dimension(L*W*H):

-

2000 x 1550 x 850 mm

-

Weight (T):

-

5 T

-

Power (kW):

-

3

-

Product Name:

-

Mini melting furnace

-

Melting Material:

-

Ferro scrap,alloy,aluminium ect.

-

Application:

-

Melting iron

-

Melting Rate:

-

420 kg / h

-

Power Factor after Compensating:

-

0.97 CosO

-

Rating of blower:

-

2.2 kw

-

Port:

-

Xiamen,Fuzhou,Quanzhou

-

Color:

-

Support customized

-

Max temperature:

-

500C - 1800C (custom Made)

Quick Details

-

Place of Origin:

-

Fujian, China

-

Marketing Type:

-

metal casting machine

-

Brand Name:

-

DL Induction Melting Furnace

-

Voltage:

-

380 v

-

Dimension(L*W*H):

-

2000 x 1550 x 850 mm

-

Weight (T):

-

5 T

-

Power (kW):

-

3

-

Product Name:

-

Mini melting furnace

-

Melting Material:

-

Ferro scrap,alloy,aluminium ect.

-

Application:

-

Melting iron

-

Melting Rate:

-

420 kg / h

-

Power Factor after Compensating:

-

0.97 CosO

-

Rating of blower:

-

2.2 kw

-

Port:

-

Xiamen,Fuzhou,Quanzhou

-

Color:

-

Support customized

-

Max temperature:

-

500C - 1800C (custom Made)

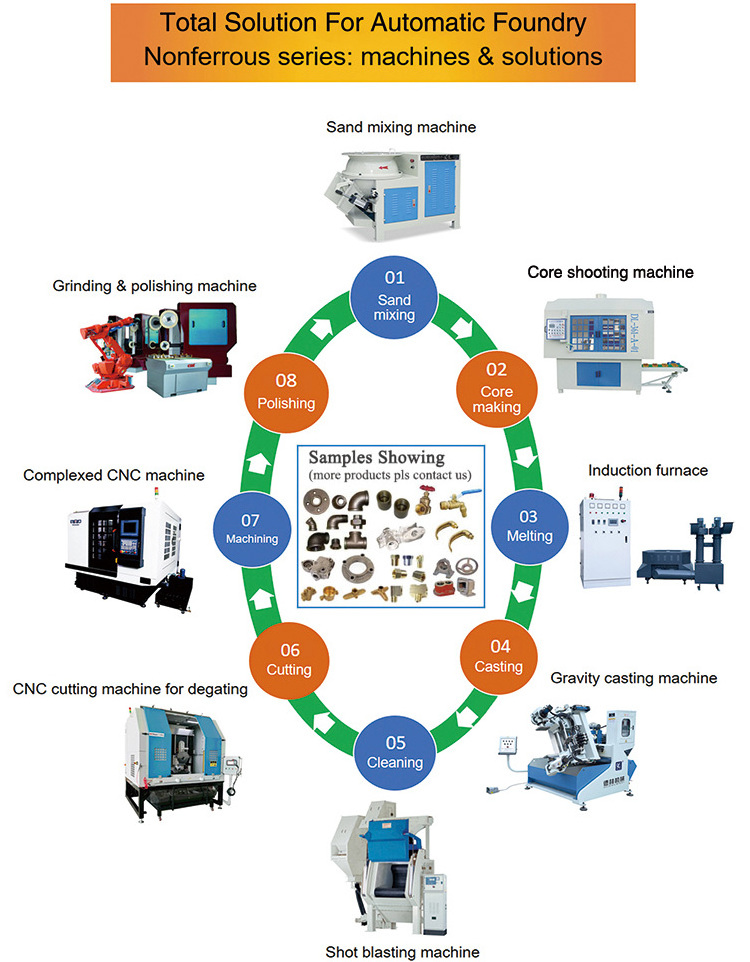

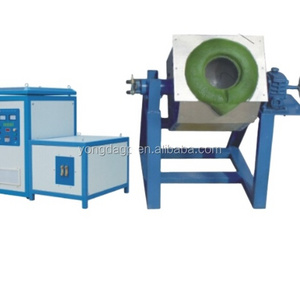

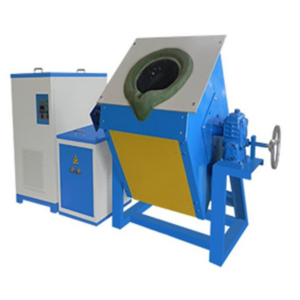

Hot Sale Induction Furnace

Furnace Main Function

1. Turn on and turn off easily,and power save.

2. Adopt constant power to control the circuit, furnace can maintain constant power while melting and keep faster melting rate.

3. Set up over voltage, over current and water deficient protector, and run safely.

4. The motherboard of furnace adopts CAD technology, integrated circuit board, low-fault-rate, easy-manipulating,effortless maintenance.

5. Zero voltage starts up softly, high initial owner, no impact for the furnace electric network.

6. Apply to melting ferrous metal and non-ferrous metal materials like copper, brass, zinc,steel,iron,stainless steel alloy,metal ore,etc. .

Furnace Specification

| Item No. | DL - GYT - 12 |

| Rated Capacity of Furnace | 1 t |

| Rated Capacity of Furnace | 1.2 t |

| Power Rating | 125 kw |

| Voltage Rating | 380 v |

| Voltage Range | 90 - 380 v |

| Melting Rate ( Brass ) | 420 kg / h |

| Weight of Furnace | ~ 5 t |

| Rating of Blower | 2.2 kw |

|

Size of Appearance of Air - Cooling Furnace ( L*W*H ) |

power distribution cabinet : 1050 x 1000 x 2000 stove : 2000 x 1550 x 850 |

|

Size of Appearance of Water - Cooling Furnace ( L*W*H ) |

power distribution cabinet : 1600 x 600 x 2000 stove : 2000 x 1550 x 850 |

* some parameters can be customised by client's requirement.

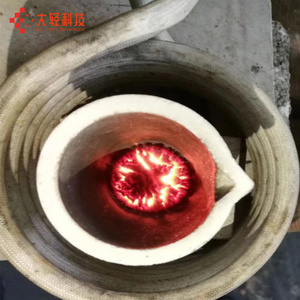

Furnace Work Diagram

Melting Materials

Induction Furnace Assembly Process

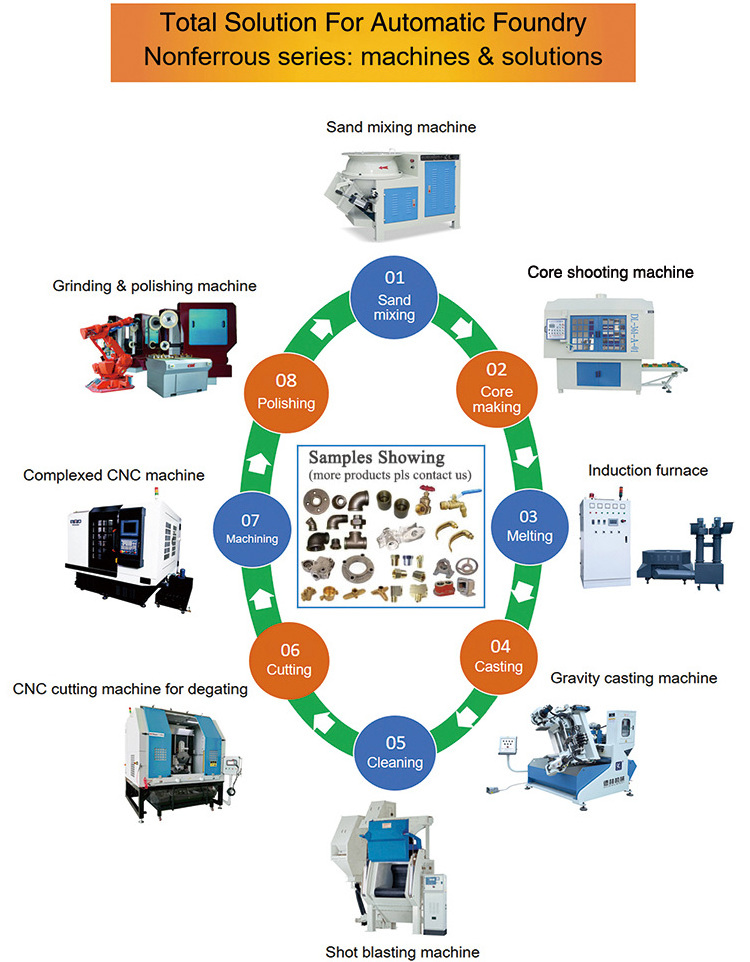

Related Machine ( we have the foundry whole produciton line machinery,which widely used to processing plumbing, sanitaryware, car spares, vaives, iron cast lines and so on. )

Main equipment : a utomatic SPM m achining e quipment , such as h orizontal CNC drilling / milling / tapping machine ; automatic sand mo u lding machine, low-pressure die casting machine, g ravity casting machine, furnace, core shooting machine, mixing sand machine, shot blasting machine (abrator),polishing machine e tc .

1. Before payment

a. Free contact for the most suitable furnace machine.

b. Free professional design for each customer especially.

c. Welcome to visit our factory.

2. After-Sales Service

We will send engineers / technicians to make commissioning at buyer’s factory, train the furnace works well, and also supply the technical support for free and spare parts at good price always.

3. Guarantee Period

One year. During the guarantee period, the seller guarantee to solve all problems may occur due to furnace's quality or wrong design, and to provide all necessary spare parts for repair, Seller can send the technician to buyer's factory on seller's account if problem is serious and can't be solved by Buyer.

4. Payment Terms

30% as deposit, 70% after the melting furnace is ready before delivery.

5. Lead Time

Our delivery time generally it is 20-30 days if the furnace are in stock , or it is 30-50 days if the induction furnace are not in stock, it is according to quantity.