Application for portable induction heater

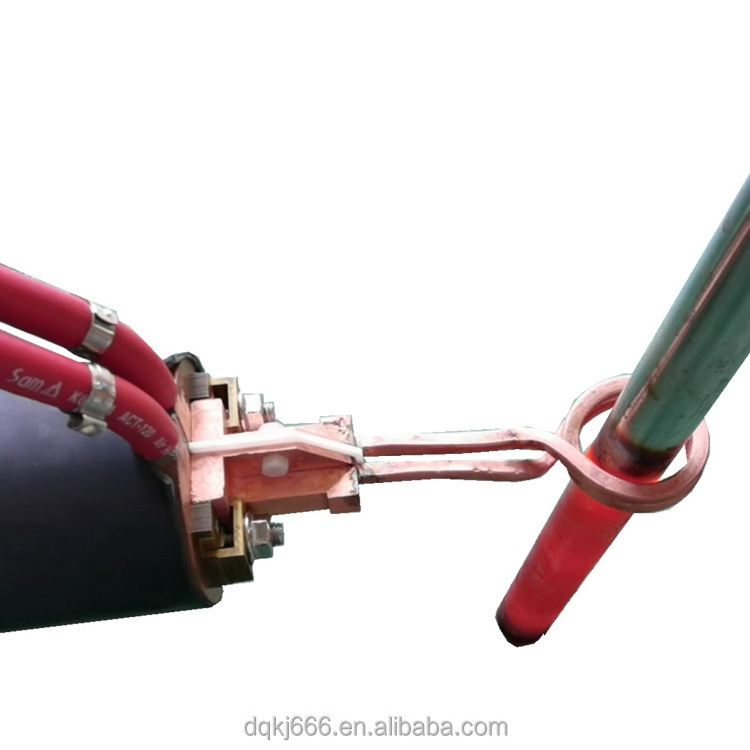

1. metal tube welding:

such as copper tube, steel tube, and aluminum tube’s butt welding, plug welding and welding sets.

2. alloy cutter welding:

such as alloy turning, milling cutter, planer, saw blades, reamer, boring knife.

3. carbide saw blade welding:

diamond saw blade welding, marble saw blade welding,woodworking saw blade welding, cut grass piece of welding, cut aluminum welding,

4. metal welding:

such as: towel rack, soap nets, towel holder, auto-accessories,moto accessories, metal terminals, hardware pieces, electric heating tube parts and fasteners.

5. customized service:

make machine according to customers' actual working situation.

Main Characteristics for induction brazing equipment:

1. Adopted European MOSFET, IGBT solid power module and advanced inverter technology.

2. Can set the time of three stages:“Heating”,”Maintain Temperature”,”Cooling”,separately.Furthermore,the function of adjusting the power of ”Maintain Temperature” independently will be effective to control the heating curve and the heating temperature.

3. Include “over-current, over voltage, water shortage, lack of phase and other fault state self-protected and display”,also some other necessary functions which will ensure our heater’s higher reliability and durability.

4. Easily operate and the output voltage is safe for operator.

5. Hundred Percent Rated Duty Cycle design,can work 24 hours continuously.