- Product Details

- {{item.text}}

Quick Details

-

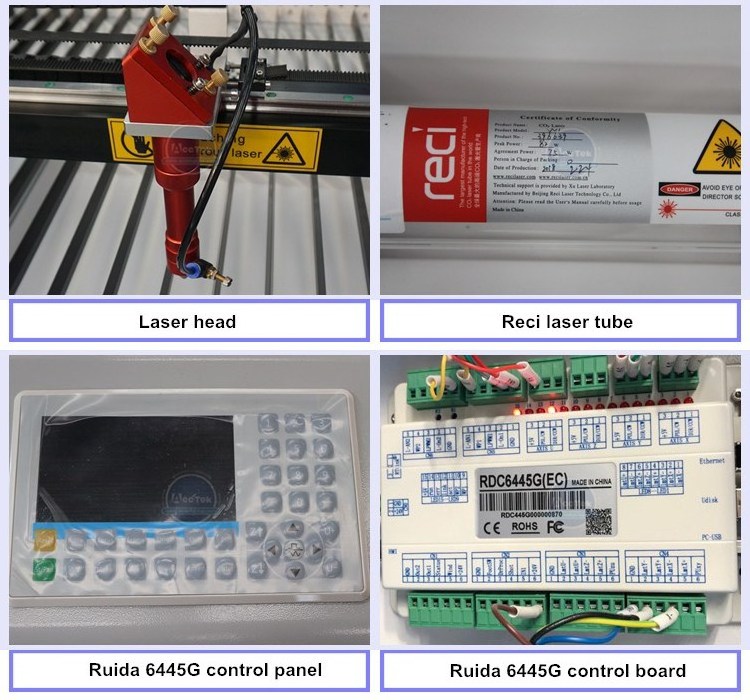

Control System Brand:

-

RuiDa

-

Cutting Area:

-

1300*1800mm (y*x)

-

Cutting Thickness:

-

0-10mm

-

Control Software:

-

Ruida

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AccTek

-

Weight (KG):

-

700 KG

-

Core Components:

-

laser fabric cutting machine

-

Keyword:

-

laser fabric cutting machine

-

Laser type:

-

Seal co2 glass laser tube

-

Laser tube:

-

90W (option:100W, 130W, 150W)

-

Lifetime:

-

8 000-10 000 Hhours

-

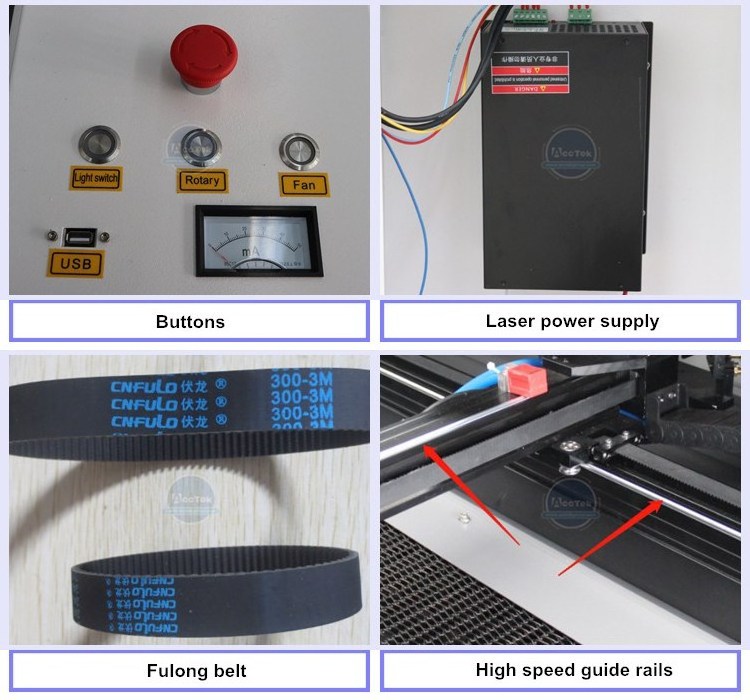

Transmission:

-

Belt transmission

-

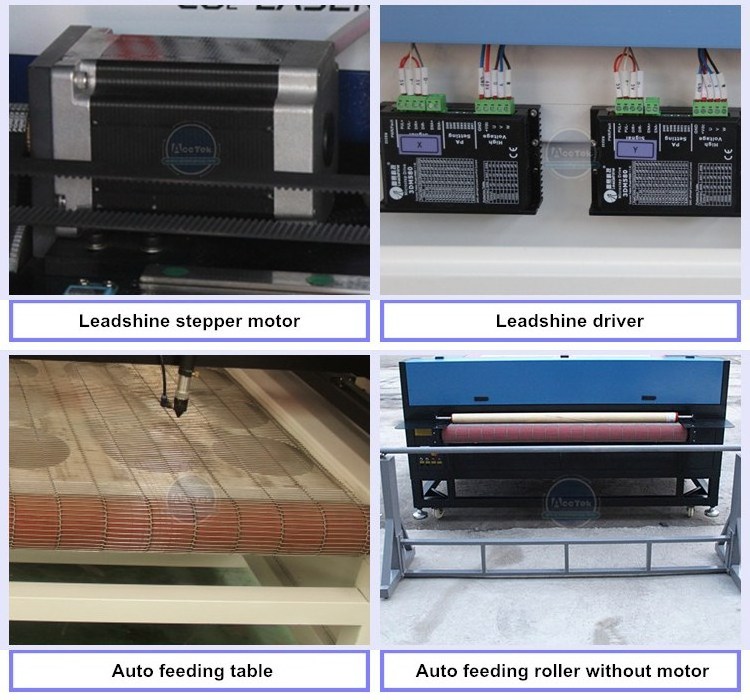

Driving system:

-

High precision 3-phase stepper motor

-

Cooling system:

-

Water pump or water chiller

-

Worktable:

-

Auto feeding worktable

-

Auto feeding roller type:

-

Auto feeding roller without motor

-

Power supply:

-

220V 1 phase (110v can be customized)

Quick Details

-

Laser Type:

-

CO2

-

Cutting Speed:

-

200-600 mm/s

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

RuiDa

-

Cutting Area:

-

1300*1800mm (y*x)

-

Cutting Thickness:

-

0-10mm

-

Control Software:

-

Ruida

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AccTek

-

Weight (KG):

-

700 KG

-

Core Components:

-

laser fabric cutting machine

-

Keyword:

-

laser fabric cutting machine

-

Laser type:

-

Seal co2 glass laser tube

-

Laser tube:

-

90W (option:100W, 130W, 150W)

-

Lifetime:

-

8 000-10 000 Hhours

-

Transmission:

-

Belt transmission

-

Driving system:

-

High precision 3-phase stepper motor

-

Cooling system:

-

Water pump or water chiller

-

Worktable:

-

Auto feeding worktable

-

Auto feeding roller type:

-

Auto feeding roller without motor

-

Power supply:

-

220V 1 phase (110v can be customized)

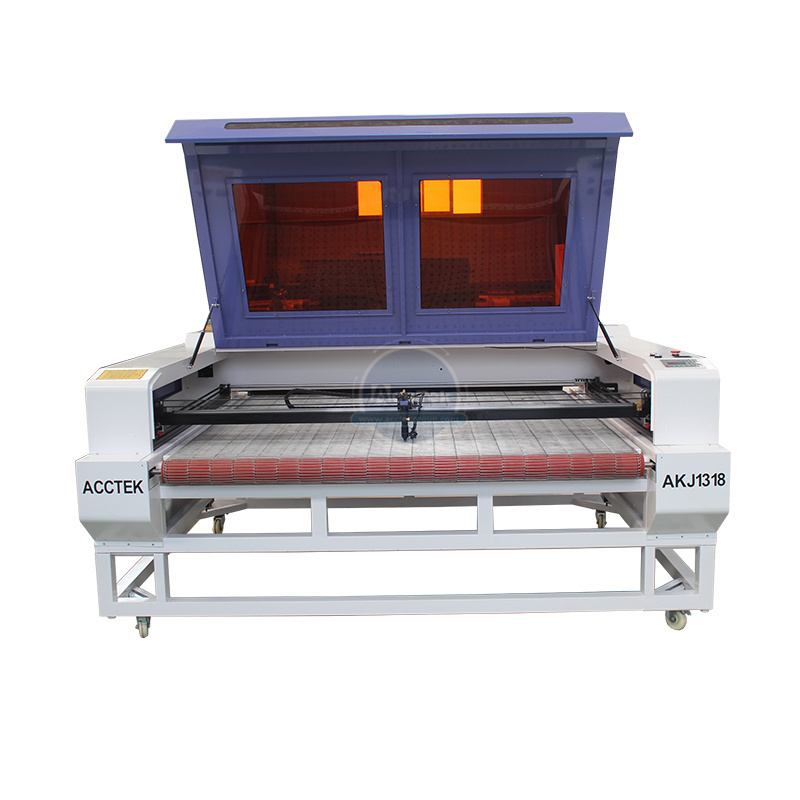

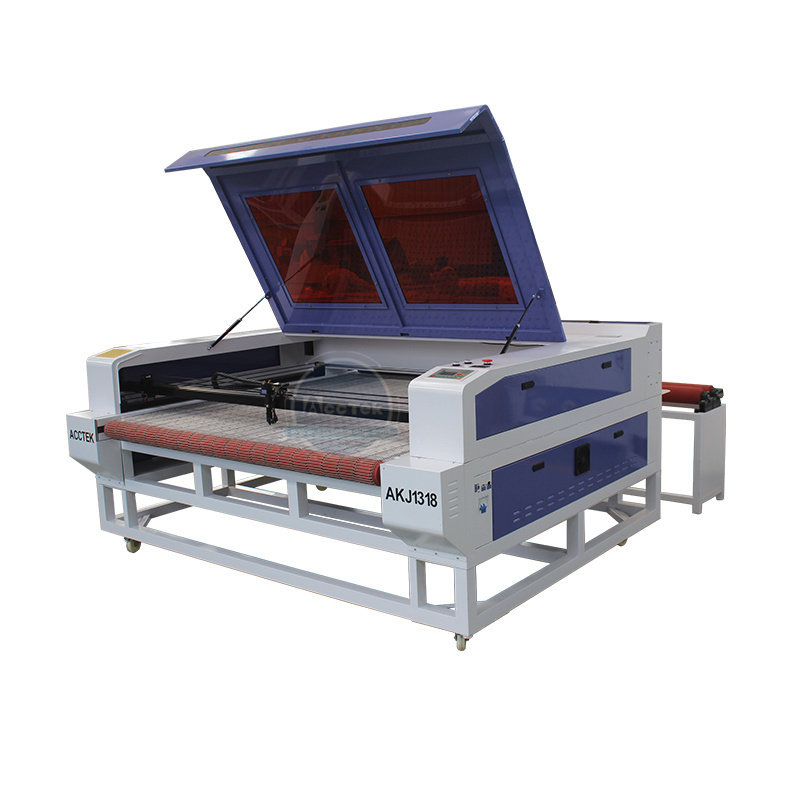

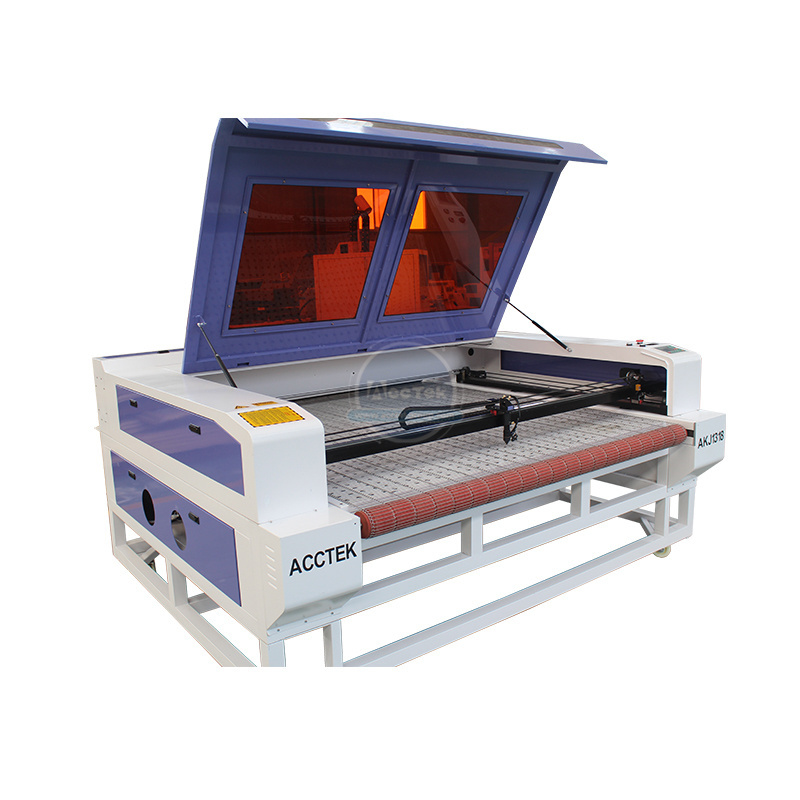

High Speed Auto Feeding CNC Laser Fabric Cutting Machine For Making Clothes AKJ1318

Machine Show

Machine Advantages

1)

Specially caters to small batch and much varieties garment fabrics cutting, especially suitable for made-to-measure clothing.

2)

Effective cutting area is 1300*1800mm. Machine can cut fabrics of any graphics within the cutting area with smooth cutting edge, automatic edge-sealing and no fraying.

3)

Conveyor working table with vacuum adsorption function ensures smooth cutting fabric.

4)

Following top exhaust suction system to synchronize laser head and exhaust suction system. Good suction effect, saving energy.

5)

Optional automatic feeding and rewinding system with auto-position correcting device realizes precise feeding and cutting. The system can do extra-long nesting and full format continuous auto-feeding cutting on a single pattern that exceeds the cutting area of the machine.

6)

Optional projection system, large area recognition system and pattern copying system, applicable to garment with stripes/plaids auto-recognition cutting.

Detail Show

Technical Parameters

|

Model

|

AKJ1318

|

|

X,Y Working Area

|

1300*1800mm

|

|

Laser Power

|

90W (option: 100W, 130W, 150W)

|

|

Laser type

|

Sealed co2 laser tube

|

|

Lifetime of Laser Tube

|

8 000-10 000 hours

|

|

Control System

|

Ruida (USB interface)

|

|

Driving System

|

Leadshine Stepper motor and driver

|

|

Engraving Speed

|

0-600mm/s

|

|

Cutting Speed

|

0-200mm/s

|

|

Resetting Positioning Accuracy

|

±0.03mm

|

|

Working Table

|

Conveyor belt

|

|

Graphic Format Supported

|

BMP, PLT, DST, DXF, and AI

|

|

Accessories

|

Exhaust Fan 550w, Air pump

|

|

Power Supply

|

220V±10% 50Hz or 110V±10% 60Hz

|

|

Package Dimension

|

2620*2150*1360mm

|

Application

1)

Fast fashion apparel and made-to-measure garment cutting

2)

Career suits, business suits and uniforms cutting

3)

Garment with stripes/plaids fabric cutting

4)

Digital printing fabric for sportswear cutting

5)

Zephyr garment and evening dress cutting

6)

Garment pattern cardboard cutting and marking

Working Samples

After Sale Services

1) Guarantee

36 months guarantee of the whole machine, 6 months

guarantee of the laser tube.

2) Software issue

Our technician is able to re-install or set up by remote for free.

3) Hardware issue

Main parts(excluding the consumables) shall be replaced/repaired free of charge, if there is any problem during the warranty period.

4) Support online

Our technician is able to teach you online to run the machine or eliminate the fault for free.

5) Training in AccTek factory

We are able to train your staff after placed order in our factory for free.

6) On-site training

(Recommended, the most effective way)

We are able to send technician to your workshop to do the installation and training.

You will need bear the related costs(flight, visa, hotel, training costs, etc.)

About AccTek

Hot Searches