- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZOZEN

-

Design fuel:

-

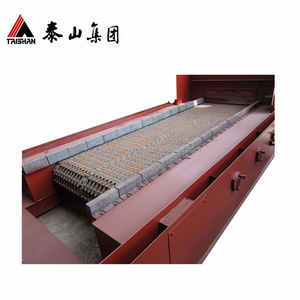

chain grate Coal firing system with standard accessories

-

Brand:

-

ZOZEN

-

Product thermal capacity:

-

10 t/h

-

Outlet temperature:

-

184-350 ℃

-

Feature:

-

Low Operating Cost

-

Operation:

-

Industrial Intelligent Controller

-

Advantages:

-

Top 1 A-Class Boiler

-

Color:

-

Customer's Requirement

Quick Details

-

Type:

-

Chain Grate Coal

-

Weight (KG):

-

100000

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ZOZEN

-

Design fuel:

-

chain grate Coal firing system with standard accessories

-

Brand:

-

ZOZEN

-

Product thermal capacity:

-

10 t/h

-

Outlet temperature:

-

184-350 ℃

-

Feature:

-

Low Operating Cost

-

Operation:

-

Industrial Intelligent Controller

-

Advantages:

-

Top 1 A-Class Boiler

-

Color:

-

Customer's Requirement

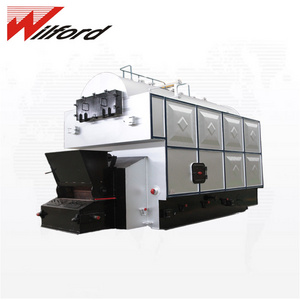

SZL series vertical dual drums chain grate water tube steam and hot water boiler, adopts quick fitting and assembly structure. The 4-6t/h boiler is of quick fitting tube structure, exit shop after completely assembled, the boiler of 6-35t/h is composed of 2 main components. The upper assembled component is the boiler proper heat absorbing part, and the lower assembled component is of combustion equipment. The former part of the boiler proper is arranged a membrane wall, the upper part of it is connected to boiler cylinder, and its lower part is connected to collective chest, so as to form a combustion room and absorb the radiated heat from the furnace. Its rear part is arranged with dense convection tubes between upper and lower boiler cylinders. The high temperature smog after combustion shall stand for twice returning flushing transversely to the heat accepting surfaces, and shall be introduced to coal saver singly arranged, and flow into duster and exhausted from chimney in the end.

materials, wine, hospital

|

Model

|

Rated evaporation(t/h)

|

Rated working pressure(MPa

|

Rated steam temperature

|

Thermal efficiency(%)

|

|

SZL4-1.25-AI

|

4

|

1.25

|

194

|

82.8

|

|

SZL4-1.60-AI

|

4

|

1.6

|

204

|

82.8

|

|

SZL4-2.45-AI

|

4

|

2.45

|

225

|

82.8

|

|

SZL6-1.25-AⅡ

|

6

|

1.25

|

194

|

82.8

|

|

SZL6-1.60-AⅡ

|

6

|

1.6

|

204

|

82.8

|

|

SZL6-2.45-AⅡ

|

6

|

2.45

|

225

|

82.8

|

|

SZL8-1.25-AⅡ

|

8

|

1.25

|

194

|

83.2

|

|

SZL8-1.60-AⅡ

|

8

|

1.6

|

204

|

83.2

|

|

SZL8-2.45-AⅡ

|

8

|

2.45

|

225

|

83.2

|

|

SZL10-1.25-AⅡ

|

10

|

1.25

|

194

|

83.2

|

|

SZL10-1.60-AⅡ

|

10

|

1.6

|

204

|

83.2

|

|

SZL10-2.45-AⅡ

|

10

|

2.45

|

225

|

83.2

|

|

SZL20-1.25-AⅡ

|

20

|

1.25

|

194

|

85.8

|

|

SZL20-1.60-AⅡ

|

20

|

1.6

|

204

|

85.8

|

|

SZL20-2.45-AⅡ

|

20

|

2.45

|

225

|

85.8

|

|

SZL30-1.25-AⅡ

|

30

|

1.25

|

194

|

86

|

|

SZL30-1.60-AⅡ

|

30

|

1.6

|

204

|

86

|

|

SZL30-2.45-AⅡ

|

30

|

2.45

|

22 5

|

86

|

|

SZL35-1.25-AI

|

35

|

1.25

|

194

|

82.8

|

|

SZL35-1.60-AI

|

35

|

1.6

|

204

|

82.8

|

|

SZL35-2.45-AI

|

35

|

2.45

|

225

|

82.8

|

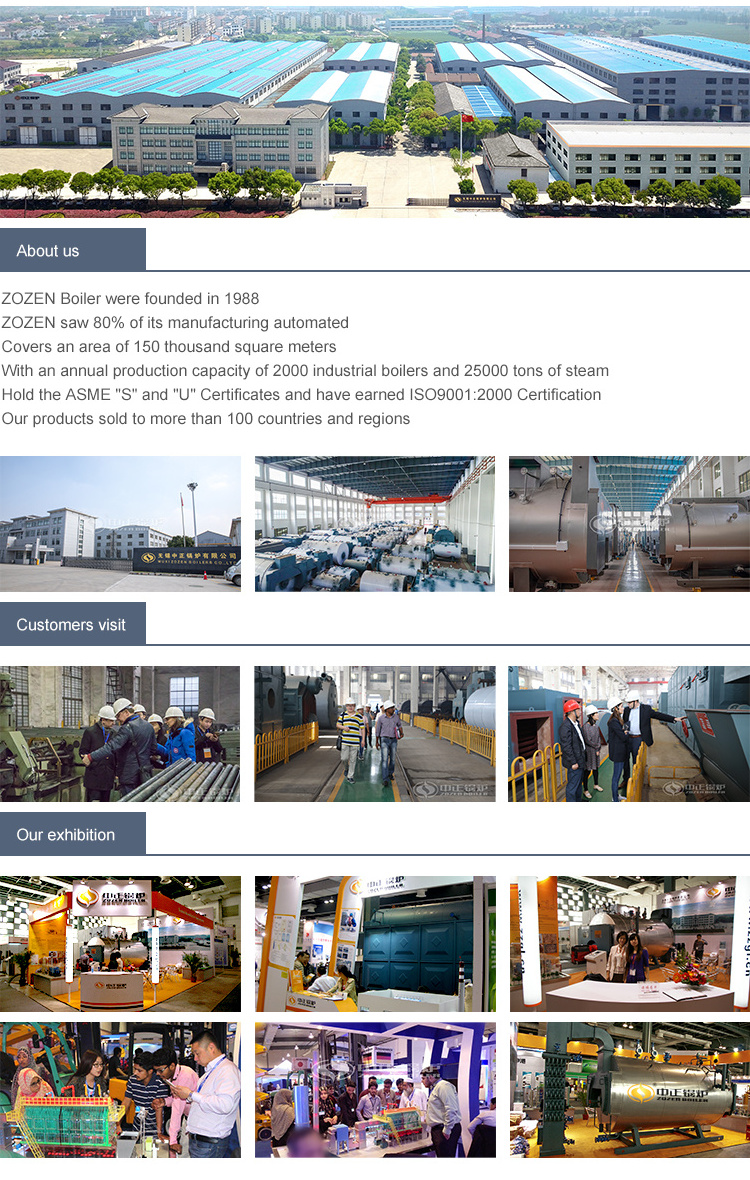

1. How can you get the best price quickly?

(1) We need to know the boiler capacity, the fuel you plan to use and the steam pressure you need, and then we can confirm the boiler model.

(2) Customer needs to provide us your name, email address and company name, and then we will send you price list immediately.And if you use whatsapp, skype or wechat, you can provide us your ID, it will be more convenient for our communication.

2. Why should you believe our boiler quality?

(1).Strength calculation report with applied materials information;

(2).100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3).100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler;

(4).Hydrostatic test: ensure the standard working pressure and safety;

(5).Third-party inspection report:By Jiangsu Boiler Inspection Institute;

(6).Passed ISO:9001 ,ISO14001,OHASA18001 and ASME(S and U) and A-class boiler certificate.

3. Quality warrantee

The seller guarantee quality of the machines for a period of 12 months from the date of trial run finish, but not to exceed 18 months from date on which the goods leave factory. If any parts (excluding easily damaging parts) are found defective in quality in the first year, the seller should replace free-of-cost.

4. Quality warrantee

The seller guarantee quality of the machines for a period of 12 months from the date of trial run finish, but not to exceed 18 months from date on which the goods leave factory. If any parts (excluding easily damaging parts) are found defective in quality in the first year, the seller should replace free-of-cost.

5.Terms of payment

T/T 30% of total contract value as down payment;

T/T or L/C 70% of total contract value before delivery.

6.Claim

Any claims by the buyers regarding the machines shipped should be filed within 30 days after arrival of machines at the destination specified in the relative B/L and supported by a survey report issued by a surveyor approved by the sellers, otherwise the sellers shall refuse to consider. Claims in respect of matters within responsibility of insurance company and/or shipping company will not be considered by the seller.

7. What is the using life of your boiler?

A:Normally the boiler is designed for 20 years life span, but with right operation and good maintenance,the boiler can be used for 20-25 years.